Water system electrolyte and application thereof

A water-based electrolyte and electrolyte technology, applied in the field of electrochemical energy storage, can solve the problems of low decomposition voltage, restricting the development of water-system energy storage, hydrogen evolution, oxygen evolution reaction, etc., to increase the decomposition voltage, improve the capacity retention rate and use Life, the effect of inhibiting electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The concrete composition of the aqueous electrolyte of this example is water, potassium acetate, lithium acetate, and its preparation method is as follows:

[0026] Each component was weighed according to the weight ratio of water / potassium acetate / lithium acetate=1.5 / 7.5 / 1, and dissolved in water to obtain the aqueous electrolyte solution of this example. Wherein, potassium acetate accounts for 75% of the total mass fraction.

[0027] In addition, an aqueous electrolyte with a low concentration of potassium acetate was prepared as a comparison. Specifically, each component was weighed according to the weight ratio of water / potassium acetate / lithium acetate=8 / 1 / 1, and dissolved in water to obtain a potassium acetate concentration of 10% by mass aqueous electrolyte, as a comparison.

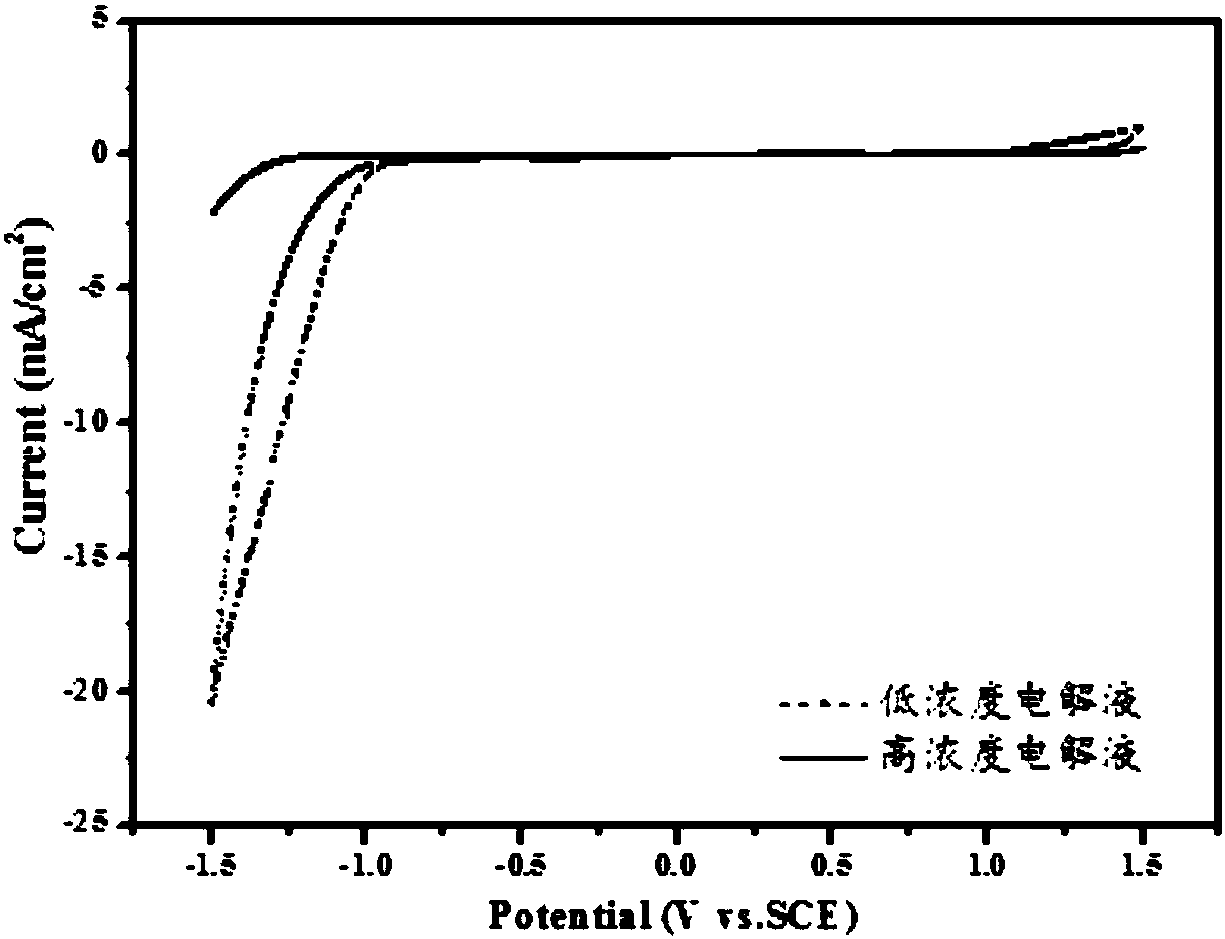

[0028] Three-electrode cyclic voltammetry was used to test the cyclic voltammetry curve of the aqueous electrolyte prepared in this example, wherein the working electrode and the counter e...

Embodiment 2

[0032] The concrete composition of the aqueous electrolyte of this example is water, potassium acetate, lithium acetate, and its preparation method is as follows:

[0033] Each component was weighed according to the weight ratio of water / potassium acetate / lithium acetate=1 / 7 / 1, and dissolved in water to obtain the aqueous electrolyte solution of this example. Among them, potassium acetate accounts for 77.8% of the total mass fraction.

[0034] Using the same method and conditions as in Example 1, the cyclic voltammetry curve test was carried out on the electrolyte of this example. The results showed that the oxygen evolution potential of the anode was 1.0V (vs. SCE), and the hydrogen evolution potential of the cathode was -1.2V (vs. SCE). The voltage window reaches 2.2V.

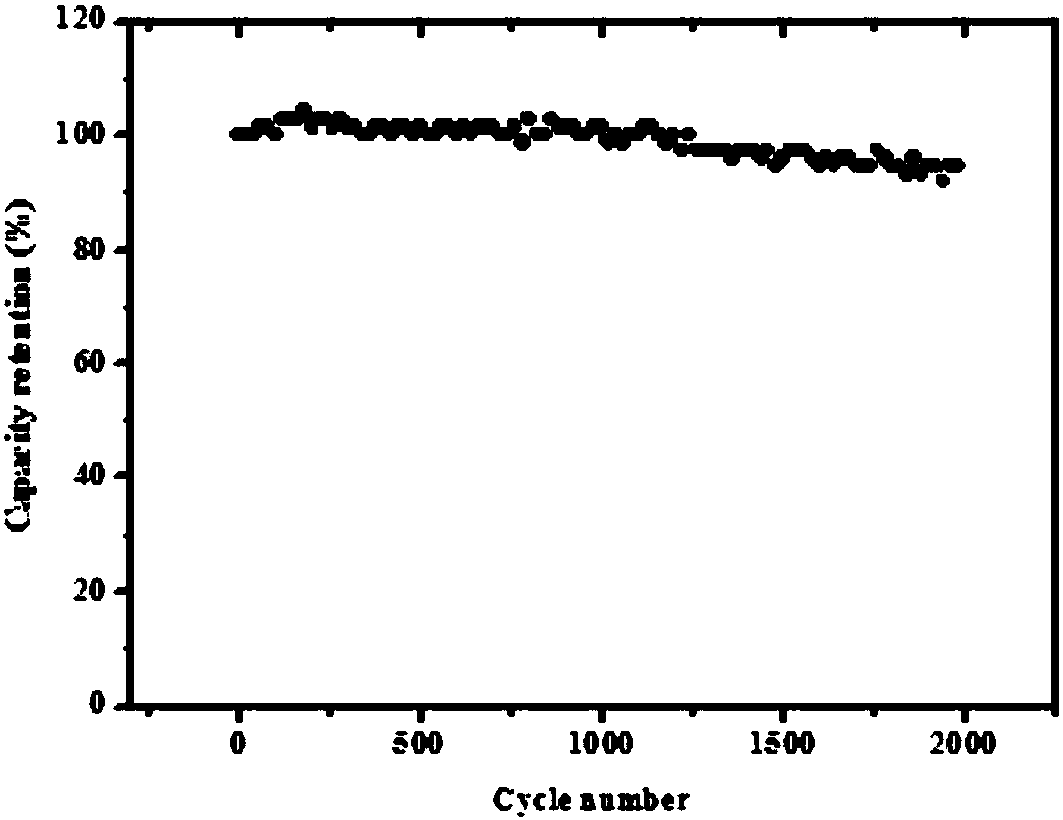

[0035] The aqueous electrolyte solution of this example is used in aqueous lithium-ion batteries, and the positive pole is commercially available spinel LiMn 2 o 4 , the negative electrode is LiTi 2 (PO ...

Embodiment 3

[0038] The concrete composition of the aqueous electrolyte of this example is water, potassium acetate, lithium sulfate, and its preparation method is as follows:

[0039] Each component was weighed according to the weight ratio of water / potassium acetate / lithium sulfate=1 / 6 / 1, and dissolved in water to obtain the aqueous electrolyte solution of this example. Wherein, potassium acetate accounts for 75% of the total mass fraction.

[0040] Using the same method and conditions as in Example 1, the cyclic voltammetry curve test was carried out on the electrolyte of this example. The results showed that the oxygen evolution potential of the anode was 1.0V (vs. SCE), and the hydrogen evolution potential of the cathode was -1.2V (vs. SCE). The voltage window reaches 2.2V.

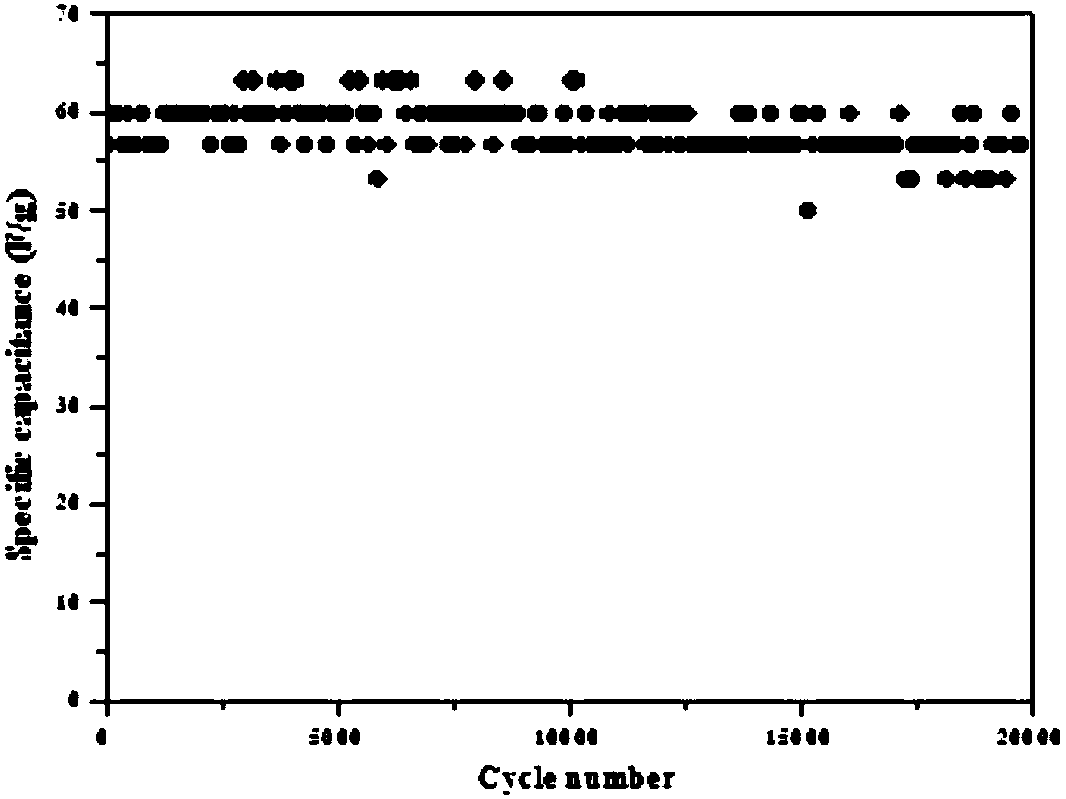

[0041] The aqueous electrolyte of this example is used in an aqueous lithium-ion hybrid supercapacitor, and the positive electrode is a commercial spinel LiMn 2 o 4 The active material of the negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com