Preparation method of low-cost all-solid-state multilevel structure transparent flexible supercapacitor

A supercapacitor and all-solid-state technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor collectors, etc., can solve the problems of high brittleness and low energy density of transparent substrate materials, and achieve high power output Good performance and flexibility, and the effect of solving the problem of brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

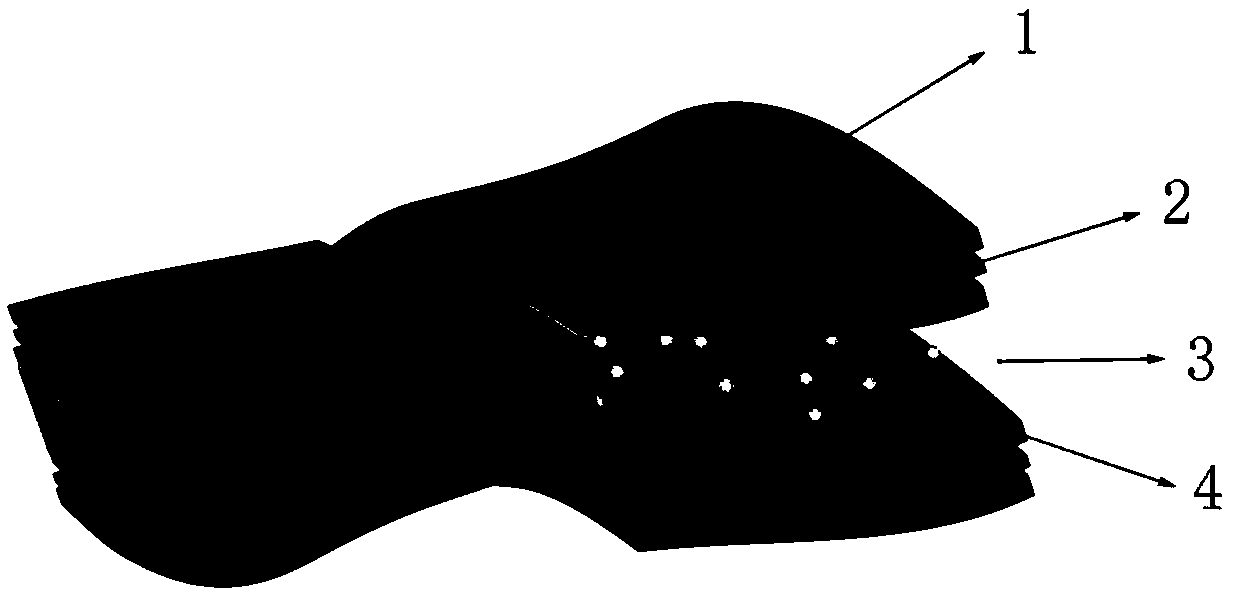

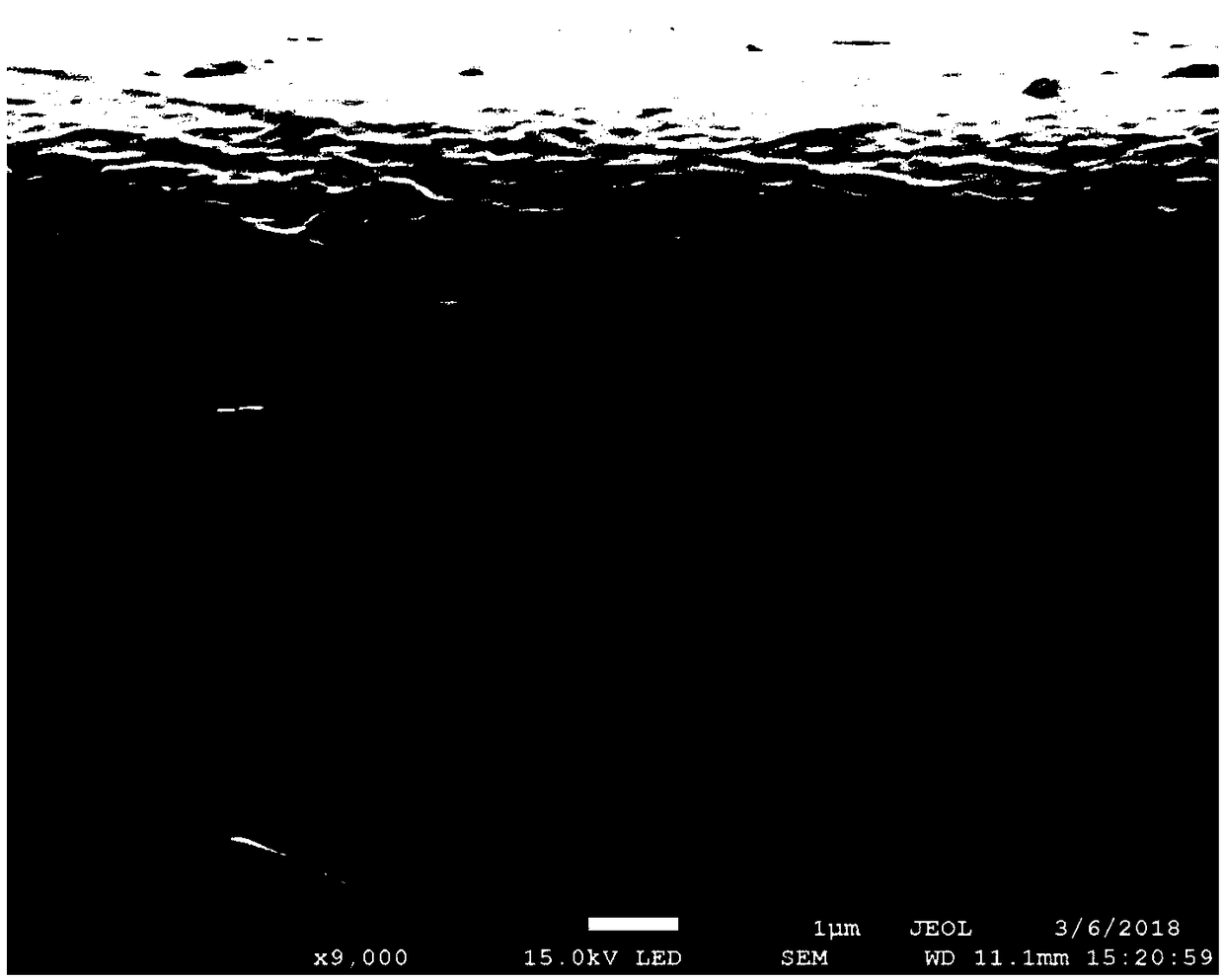

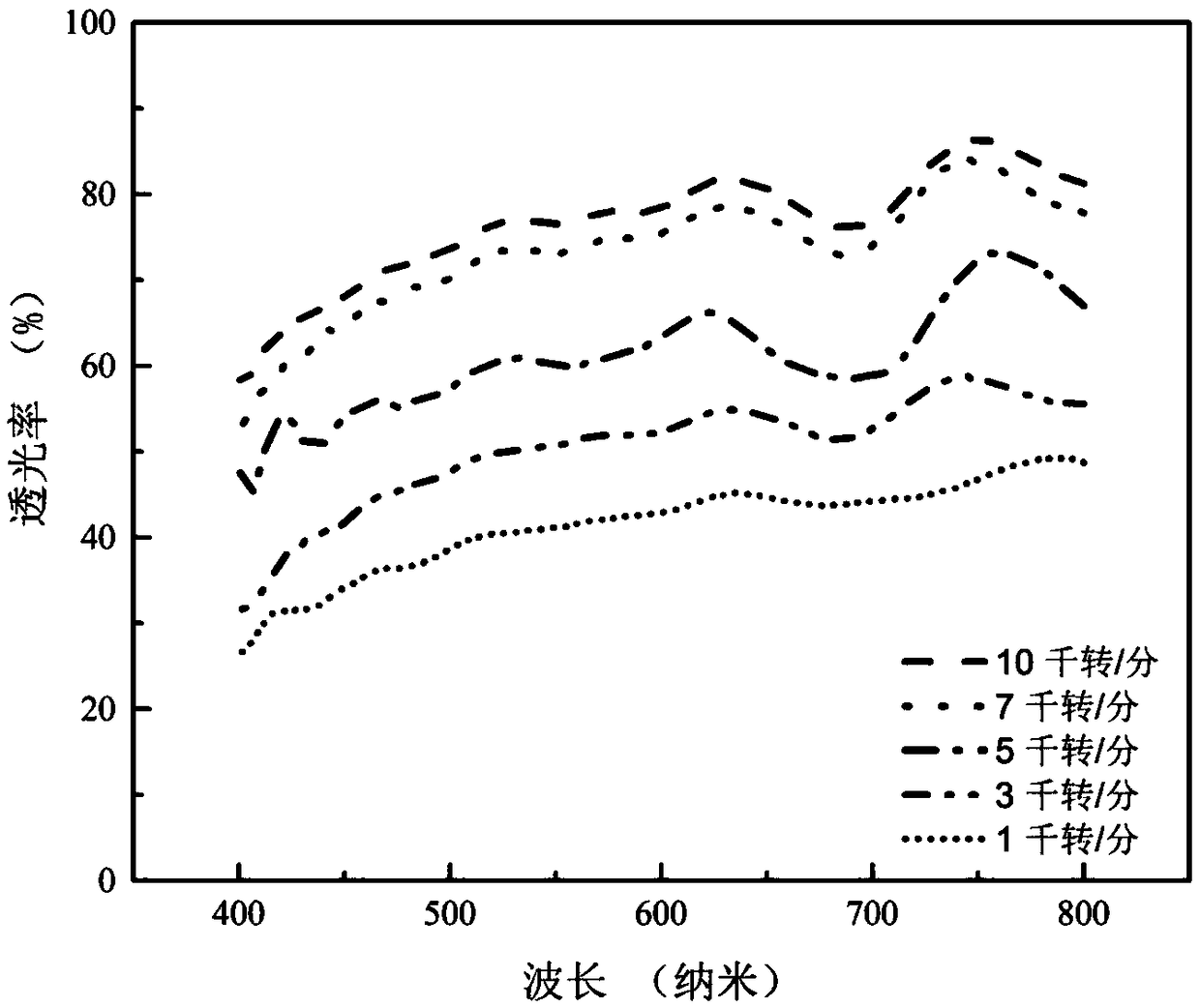

[0037] (1) Spin-coat 0.5mg / ml nano-silver wire solution (10ml) on a 10cm x 10cm PET substrate with a homogenizer, the rotation speed is 4000rpm, the spin-coating time is 40s, and then heated at 120°C for 5min with an electric heating plate, A transparent and flexible current collector whose surface is covered with a network of metal nanowires is prepared, and the thickness of the coating is 100 nm.

[0038] (2) get 50ml concentration and be that the graphene oxide solution of 5mg / ml is mixed with the hydrogen peroxide solution that 15ml mass fraction is 30%, 100 ℃ of stirring 5h, then the mixed solution is dialyzed (is about to above-mentioned mixed solution is poured in the dialysis bag, Then immerse the dialysis bag in deionized water and perform dialysis for 48 hours. The dialysis bag is specifically "MWCO: 1500D". The following dialysis steps are the same), and then pour out the solution in the dialysis bag to obtain a defect-rich graphene oxide solution with pH=7 (The sol...

Embodiment 2

[0045] (1) Spin-coat 0.5mg / ml nano-silver wire solution (10ml) on a 10cm x 10cm PET substrate with a homogenizer, the rotation speed is 4000rpm, the spin-coating time is 40s, and then heated at 120°C for 5min with an electric heating plate, A transparent and flexible current collector whose surface is covered with a network of metal nanowires is prepared, and the thickness of the coating is 100 nm.

[0046] (2) Take 50ml of graphene oxide solution with a concentration of 5mg / ml and 15ml of hydrogen peroxide solution with a mass fraction of 30%, mix them, stir at 100°C for 5h, then dialyze the mixed solution, then pour out the solution in the dialysis bag, A defect-rich graphene oxide solution with a pH of 7 was obtained (the volume of the solution remained unchanged before and after dialysis). Add 0.2g carbon nanotube and 0.1g polystyrene microspheres (the particle diameter of microsphere is 30nm) to above-mentioned defect-rich graphene oxide solution again afterwards, stir 5h...

Embodiment 3

[0052] (1) Spin-coat 0.5mg / ml nano-silver wire solution (10ml) on a 10cm x 10cm PET substrate with a homogenizer, the rotation speed is 4000rpm, and the spin-coating time is 40s, and then heated at 120°C for 5min with an electric heating plate, A transparent and flexible current collector whose surface is covered with a network of metal nanowires is prepared, and the thickness of the coating is 100 nm.

[0053] (2) Take 50ml of graphene oxide solution with a concentration of 5mg / ml and 15ml of hydrogen peroxide solution with a mass fraction of 30%, mix them, stir at 100°C for 5h, then dialyze the mixed solution, then pour out the solution in the dialysis bag, A defect-rich graphene oxide solution with a pH of 7 was obtained (the volume of the solution remained unchanged before and after dialysis). Add 0.2g carbon nanotube and 0.1g polystyrene microspheres (the particle diameter of microsphere is 30nm) to above-mentioned defect-rich graphene oxide solution again afterwards, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com