Radix ophiopogonis flavored syrup and preparation method thereof

A technology of Ophiopogon japonicus and syrup, applied in confectionery, confectionery industry, pharmaceutical formulations and other directions, can solve the problems of people's allergies and discomfort, inability to eat for a long time, complex ingredients, etc., achieve high economic effect and social value, improve taste and quality. Fragrance, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) After pulverizing Ophiopogon japonicus into 5mm particles, add 20 times the weight of distilled water, heat to boil on high heat, continue to decoct with low heat for 30 minutes, filter to obtain Ophiopogon japonicus water, and set aside;

[0022] (2) Weigh 350g of maltose, 500g of F55 fructose syrup, and 107g of Ophiopogon japonicus water, and add them to the mixing tank in turn, and keep stirring at 250rpm at 80°C until the mixed sugar solution is completely dissolved;

[0023] (3) Weigh 14g of citric acid, 8g of potassium sorbate, 1g of stevioside, 2g of guar gum, and 5g of gum arabic, add an equal amount of water to dissolve them, add them to the stirring tank one by one, and keep stirring at 300rpm for 3 minutes;

[0024] (4) Adjust the syrup to a mass percent concentration of 65% and a DE value of 57%.

Embodiment 2

[0026] (1) After pulverizing Ophiopogon japonicus into 6mm particles, add .30 times the weight of distilled water, heat to boil on high heat, continue to decoct on low heat for 30 minutes, filter to obtain Ophiopogon japonicus water, and set aside;

[0027] (2) Weigh 375g of maltose, 475g of F55 fructose syrup, and 126.5g of Ophiopogon japonicus water, and add them to the mixing tank in turn, and keep stirring at 250rpm at 80°C until the mixed sugar solution is completely dissolved;

[0028] (3) Weigh 16g of citric acid, 9g of potassium sorbate, 1.5g of disodium glycyrrhizinate, 2.5g of guar gum, and 6g of gum arabic, add an equal amount of water to dissolve them, add them to the stirring tank one by one, and keep stirring at 300rpm for 3 minutes ;

[0029] (4) Adjust the syrup to a mass percent concentration of 70% and a DE value of 60%.

Embodiment 3

[0031] (1) After pulverizing Ophiopogon japonicus into 7mm particles, add 40 times the weight of distilled water, heat to boil on high heat, continue to decoct with low heat for 30 minutes, filter to obtain Ophiopogon japonicus water, and set aside;

[0032] (2) Weigh 400g of maltose, 450g of F55 fructose syrup, and 146g of Ophiopogon japonicus water, and add them to the mixing tank in turn, and keep stirring at 250rpm at 80°C until the mixed sugar solution is completely dissolved;

[0033] (3) Weigh 18g of citric acid, 10g of potassium sorbate, 2g of arrowroot sweetin, 3g of guar gum, and 7g of gum arabic, add an equal amount of water to dissolve them, add them to the mixing tank one by one, and keep stirring at 300rpm for 3 minutes;

[0034] (4) Adjust the syrup to a mass percent concentration of 75% and a DE value of 63%.

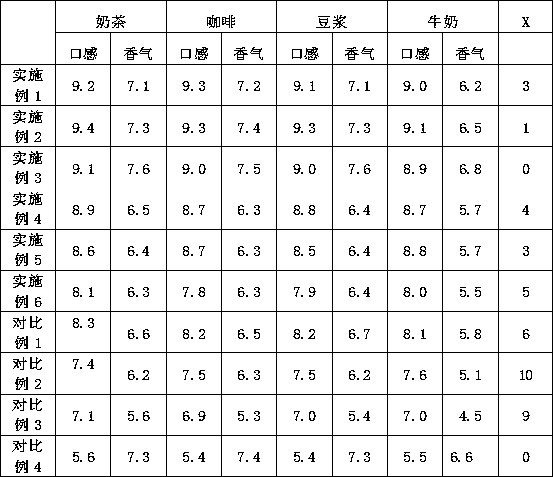

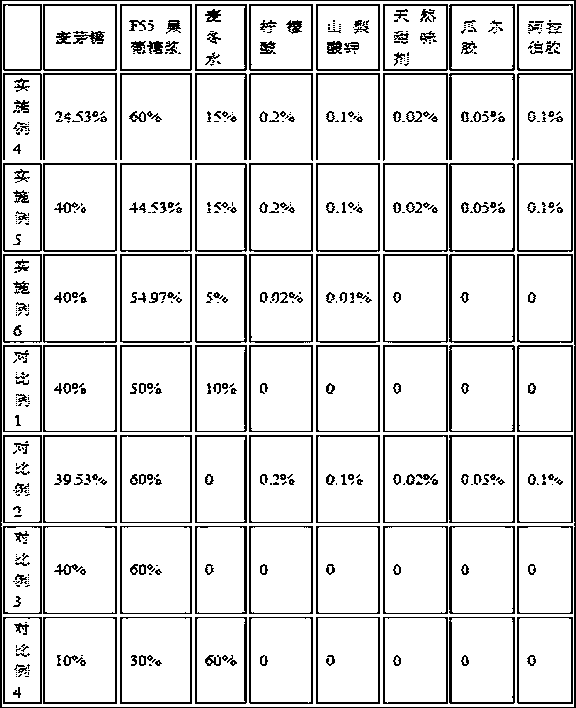

[0035] The preparation method of embodiment 4~6 and comparative example 1~4 is identical with embodiment 2, but each component weight percentage is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com