Method for assisting in fish glue soaking by combining ultrasonic waves with microwave vacuum frying

A technology of microwave vacuum frying and vacuum frying, which is applied in the direction of food science, etc., to achieve the effect of good hygienic quality, simple operation, and improved texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

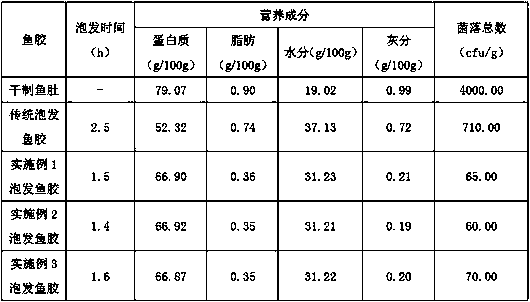

Examples

Embodiment 1

[0029] (1) Selection of raw materials and preliminary removal of impurities: select dry fish gelatin that is free from moths, odors, and deterioration, and initially remove impurities on the surface of the fish gelatin;

[0030] (2) Washing and drying: wash the isinglass pretreated in step (1), put it in an oven, and bake at 50°C for 10 minutes to remove excess water;

[0031] (3) Warm oil at low temperature: Put the isinglass dried in step (2) into a vacuum frying reactor, add soybean oil, and keep the oil warm for 30 minutes at an oil temperature of 100°C and a microwave power of 2kW until the fish The glue is translucent;

[0032] (4) Microwave vacuum frying: Put the isinglass from step (3) into the vacuum frying reactor again, and fry for 10 minutes under the conditions of vacuum degree of 0.08MPa, oil temperature of 120°C, and microwave power of 2kW , until the gelatin texture is soft, flat and full, and the honeycomb cells are evenly distributed (the end of frying shoul...

Embodiment 2

[0039] (1) Selection of raw materials and preliminary removal of impurities: select dry fish gelatin that is free from moths, odors, and deterioration, and initially remove impurities on the surface of the fish gelatin;

[0040] (2) Washing and drying: wash the isinglass pretreated in step (1), put it in an oven, and bake at 50°C for 12 minutes to remove excess water;

[0041] (3) Warm oil at low temperature: Put the isinglass dried in step (2) into a vacuum frying reactor, add soybean oil, and keep the oil warm for 30 minutes at an oil temperature of 100°C and a microwave power of 3kW until the fish The glue is translucent;

[0042] (4) Microwave vacuum frying: Put the isinglass from step (3) into the vacuum frying reactor again, and fry for 8 minutes under the conditions of vacuum degree of 0.08MPa, oil temperature of 110°C, and microwave power of 3kW , until the gelatin texture is soft, flat and full, and the honeycomb cells are evenly distributed (the end of frying should...

Embodiment 3

[0049] (1) Selection of raw materials and preliminary removal of impurities: select dry fish gelatin that is free from moths, odors, and deterioration, and initially remove impurities on the surface of the fish gelatin;

[0050] (2) Washing and drying: wash the isinglass pretreated in step (1), put it in an oven, and bake at 50°C for 10 minutes to remove excess water;

[0051] (3) Low-temperature cooking oil: Put the isinglass dried in step (2) into a vacuum frying reactor, add palm oil, and keep the oil warm for 30 minutes at an oil temperature of 105°C and a microwave power of 3kW until the fish The glue is translucent;

[0052] (4) Microwave vacuum frying: Put the isinglass from step (3) into the vacuum frying reactor again, and fry for 10 minutes under the conditions of vacuum degree of 0.09MPa, oil temperature of 130°C, and microwave power of 3kW , until the gelatin texture is soft, flat and full, and the honeycomb cells are evenly distributed (the end of frying should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com