Nickel-aluminum spinel catalyst and preparation method thereof

A nickel-aluminum spinel and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low-temperature preparation of nickel-aluminum spinel catalysts See reports and other issues, to achieve the effect of simple preparation process and low reduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

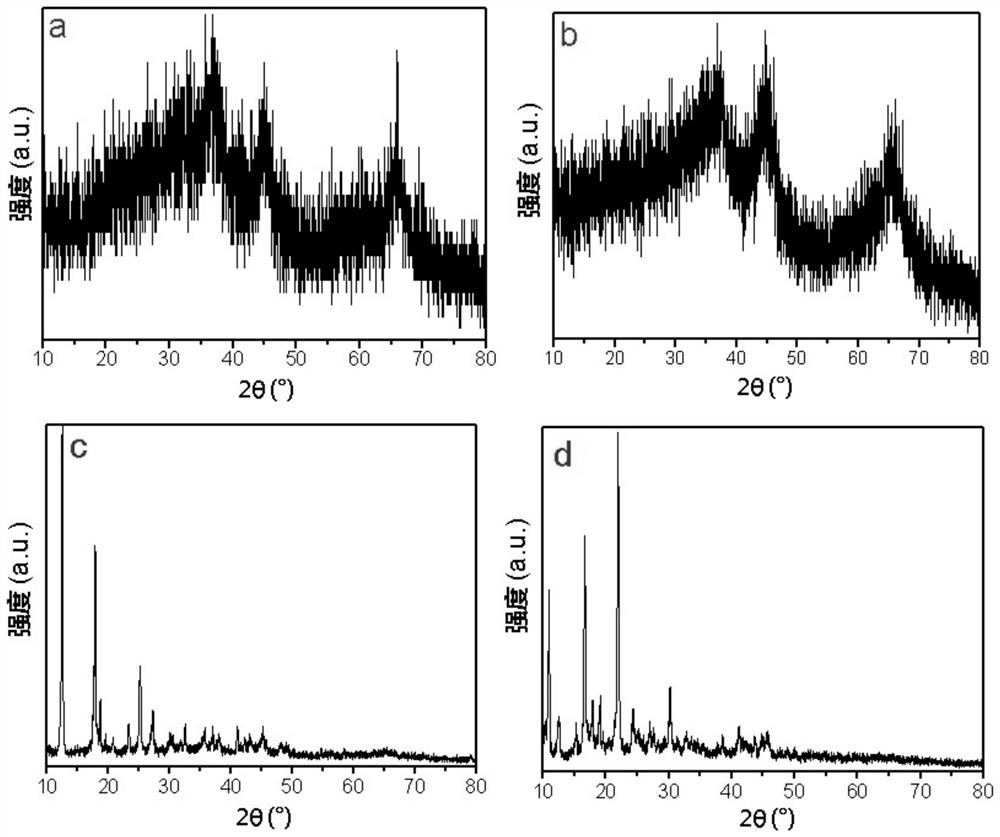

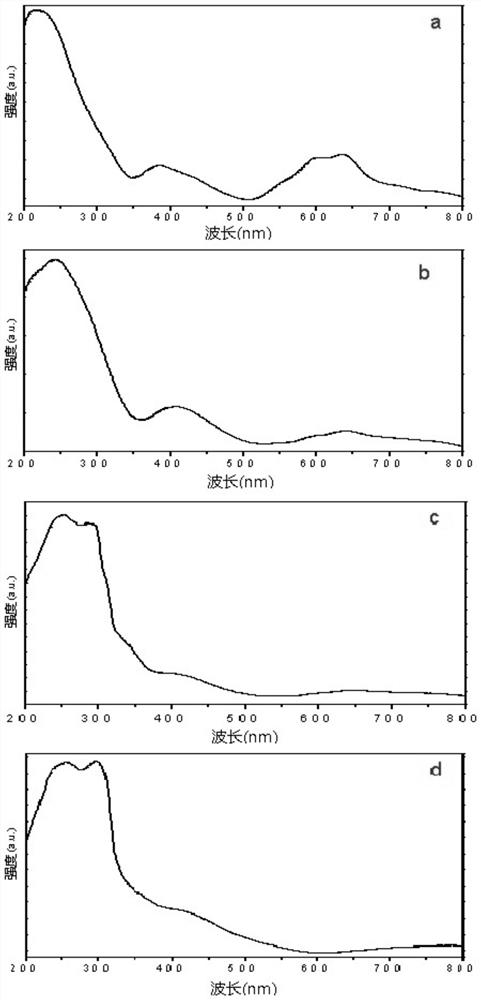

[0022] A kind of preparation method of nickel-aluminum spinel catalyst, carry out hydrothermal reaction after mixing organic matter, aluminum source and nickel source, then collect hydrothermal reaction product and roast to obtain required nickel-aluminum spinel catalyst; The organic matter is For terephthalic acid, trimesic acid or methyl trimesate, the calcination temperature is 400-600°C.

[0023] The preparation method of the nickel-aluminum spinel catalyst is synthesized by a one-step method, and the operation is simple and convenient; and the nickel-aluminum spinel catalyst can be formed by roasting at a low temperature without high temperature conditions. In addition, it should be emphasized that the preparation method of a highly dispersed and easily reducible supported nickel-aluminum catalyst provided in Chinese patent CN106582655A is an amorphous nickel-aluminum catalyst. And the present invention is by adding nickel source in situ, that is, adding organic matter, a...

Embodiment 2

[0027] A nickel-aluminum spinel catalyst, which is prepared by the preparation method of the nickel-aluminum spinel catalyst provided in Example 1, has a specific nickel-aluminum spinel structure.

[0028] Here are some experimental groups

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com