A preparation method of graphene-based self-healing superhydrophobic coating

A super-hydrophobic coating and self-healing technology, applied in coatings, pigmented coatings, antifouling/underwater coatings, etc., to achieve mild conditions, cost savings, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of self-healing superhydrophobic coating:

[0027] Mix 1 g of graphene oxide and 150 mL of absolute ethanol evenly, then ultrasonically disperse for 10 min, then add 5 g of octadecylamine to continue ultrasonic treatment for 1 h, put the ultrasonically treated dispersion in a three-necked flask, and reflux at 80 °C for reaction 24 h; cooled to room temperature, centrifuged and washed 6 times with absolute ethanol to remove unreacted octadecylamine, and dried completely in a vacuum oven at 60 °C to obtain a self-healing superhydrophobic material; the self-healing superhydrophobic material and 200 mL of a dispersion with a concentration of 0.5 mg / mL was prepared in absolute ethanol and dispersed ultrasonically for 10 min; the dispersion was suction-filtered on filter paper and dried to obtain a self-healing superhydrophobic coating.

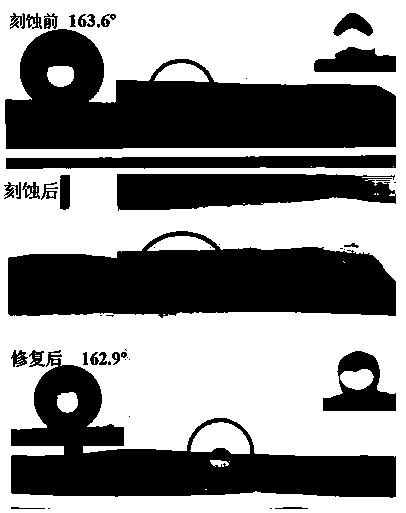

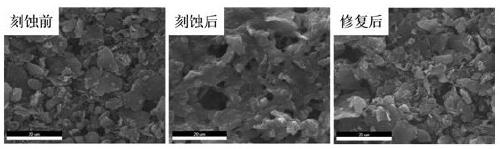

[0028] 2) Determination of coating self-healing performance:

[0029] Use YZD08-5C plasma cleaning machine (manufactured by...

Embodiment 2

[0031] 1) Preparation of self-healing superhydrophobic coating:

[0032] Mix 1 g of graphene oxide and 350 mL of absolute ethanol evenly, and then ultrasonically disperse for 20 min, then add 10 g of octadecylamine to continue ultrasonic treatment for 1.5 h, put the ultrasonically treated dispersion in a three-necked flask, and reflux at 160 °C for reaction 6 h; cooled to room temperature, centrifuged and washed 6 times with absolute ethanol to remove unreacted octadecylamine, and dried completely in a vacuum oven at 120 °C to obtain a self-healing superhydrophobic material; the self-healing superhydrophobic material and 200 mL of a dispersion with a concentration of 1 mg / mL was prepared in acetone and dispersed ultrasonically for 30 min; the dispersion was sprayed on glass and dried to obtain a self-healing superhydrophobic coating.

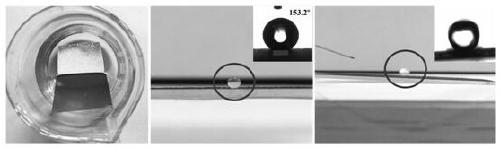

[0033] 2) Determination of coating corrosion resistance:

[0034] Use HCl, NaOH and NaCl to prepare 1 mol / L acid, alkali and salt solutions re...

Embodiment 3

[0036] 1) Preparation of self-healing superhydrophobic coating:

[0037] 1 g of graphite oxide and 500 mL of absolute ethanol were ultrasonically stripped for 30 min to obtain graphene oxide, then 15 g of octadecylamine was added to continue ultrasonic treatment for 2 h, and centrifuged with absolute ethanol for 6 times to remove unreacted octadecylamine , in a vacuum oven at 180 ℃ until completely dry to obtain a self-healing superhydrophobic material; prepare 200 mL of a dispersion with a concentration of 1.5 mg / mL and ultrasonically disperse the self-healing superhydrophobic material and N,N-dimethylformamide for 60 min; the sponge was repeatedly dipped in the dispersion and dried to obtain a self-healing superhydrophobic coating.

[0038] 2) Determination of coating UV resistance:

[0039] The coating was irradiated with ultraviolet light by an ultraviolet cross-linking instrument (manufactured by UVP Company of the United States), and the coating was taken out after 5000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com