Method for producing L-tryptophan by husk fermentation and use thereof

A technology of tryptophan and glutamic acid, applied in the direction of fermentation, etc., can solve the problem that the rice husk is not well applied, and achieve the effect of simple and easy fermentation process, increased high-value utilization, and less water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

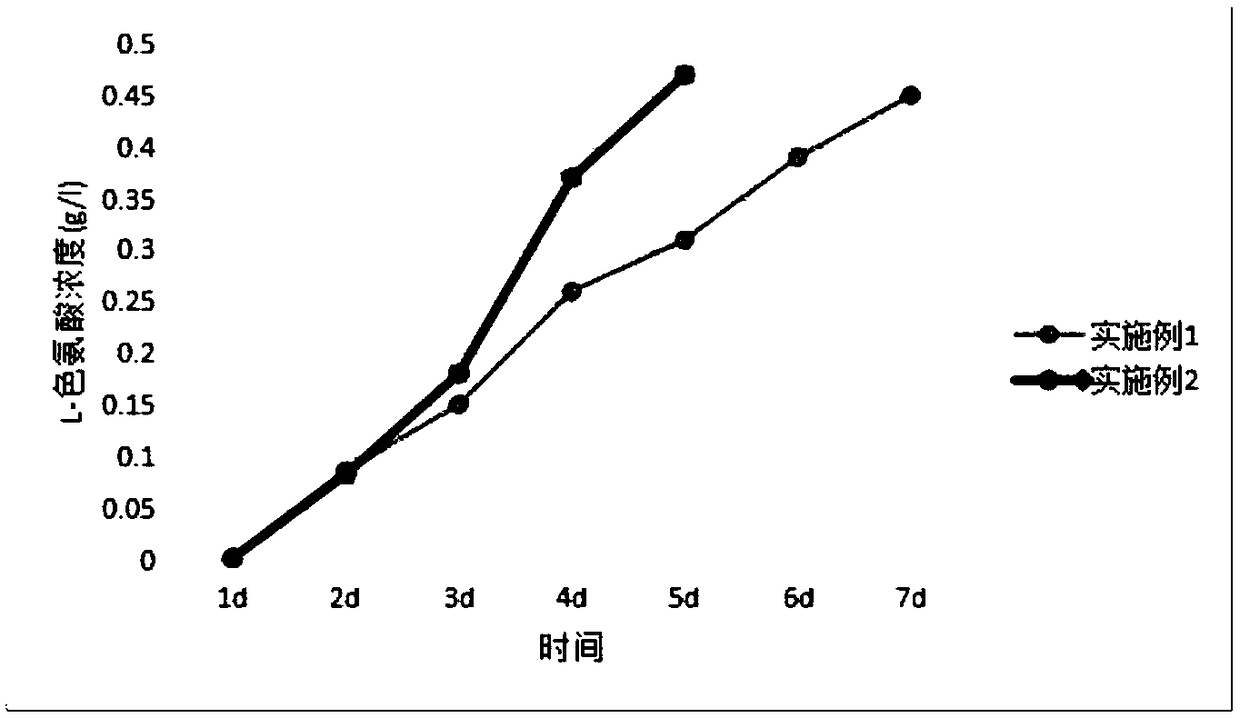

Embodiment 1

[0033] A method for producing L-tryptophan by fermenting chaff. The raw material components for L-tryptophan produced by chaff fermentation include: 40 parts of chaff, 15 parts of millet, 9 parts of pinto beans, 12 parts of fermented yeast, phosphate buffer 13 parts of solution, 25 parts of 0.05-0.2% sodium chloride solution, 14 parts of soybean cake, 13 parts of yeast extract, 13 parts of peptone and 35 parts of water.

[0034] The method for producing L-tryptophan by fermentation of chaff comprises the steps:

[0035] (1) select high-quality chaff, remove chaff such as rotten chaff, put chaff into pulverizer and be pulverized into powder for later use;

[0036] (2) Add water to the chaff powder afterward, the chaff powder is dissolved into a thick liquid, and in the thick liquid, add 50% yeast extract to become a thick liquid solution;

[0037] (3) Finally, place the thick liquid solution in a shaker at 350rpm / min, and expose it to strong sunlight for 4 days to ferment natu...

Embodiment 2

[0051] A method for producing L-tryptophan by fermenting rice husks. The raw material components for producing L-tryptophan by fermenting rice husks include: 35 parts of rice husks, 9 parts of millet, 5 parts of pinto beans, 13 parts of fermented yeast, phosphate buffer 12 parts of solution, 25 parts of 0.05-0.2% sodium chloride solution, 13 parts of soybean cake, 14 parts of yeast extract, 13 parts of peptone and 40 parts of water.

[0052] The method for producing L-tryptophan by fermentation of chaff comprises the steps:

[0053] (1) select high-quality chaff, remove chaff such as rotten chaff, put chaff into pulverizer and be pulverized into powder for later use;

[0054] (2) Add water to the chaff powder afterward, the chaff powder is dissolved into a thick liquid, and in the thick liquid, add 50% yeast extract to become a thick liquid solution;

[0055] (3) Finally, place the thick liquid solution in a shaker at 400rpm / min, and expose it to strong sunlight for 4 days to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com