Phytase-containing chicken feed and preparation method thereof

A technology of phytase chicken and production method, which is applied in animal feed, animal feed, additional food elements, etc., can solve the problems of reducing the utilization rate of metal ion protein, low utilization rate of phytate phosphorus, and high thermal stability of phytic acid, achieving Effects of avoiding active effects, reducing excretion, and increasing economic income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

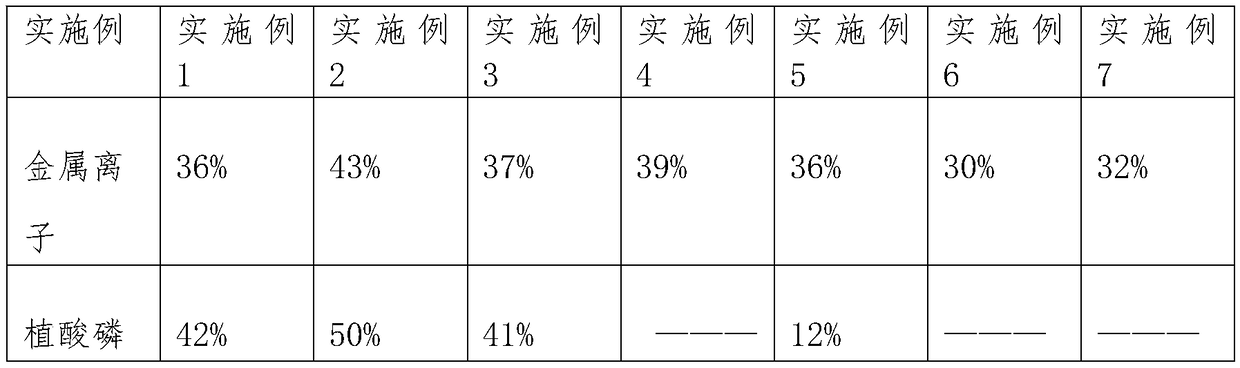

Examples

Embodiment 1

[0016] Materials: soybean meal 15kg, corn husk 1kg, bran 1kg, phytase solution 9kg, bentonite 4kg, salicylic acid 1kg;

[0017] Production method: (1), purification and optimization of single colony seeds: coating single colony seeds on a petri dish with bacterial culture medium, and cultivating to obtain single colony seeds; (2), the single colony seeds obtained in step (1) After the colony seeds are fermented into first-level solid seeds, they are inoculated into the solid medium of the second-level fermenter to obtain second-level liquid seeds; (3), main ingredients for fermentation: three solid fermentation materials of soybean meal, corn bran and bran are put into fermentation In the pool, inoculate the secondary liquid seeds, stir constantly, and ferment to obtain the fermentation material; (4), granulation: make the product obtained in step (4) into granules, then add pre-mixed enzyme-containing bentonite, and spray water Salicylic acid is enough;

Embodiment 2

[0019] Materials: soybean meal 25kg, corn husk 4kg, bran 4kg, phytase solution 13kg, bentonite 64kg, salicylic acid 6kg;

[0020] Production method: (1), purification and optimization of single colony seeds: coating single colony seeds on a petri dish with bacterial culture medium, and cultivating to obtain single colony seeds; (2), the single colony seeds obtained in step (1) After the colony seeds are fermented into first-level solid seeds, they are inoculated into the solid medium of the second-level fermenter to obtain second-level liquid seeds; (3), main ingredients for fermentation: three solid fermentation materials of soybean meal, corn bran and bran are put into fermentation In the pool, inoculate the secondary liquid seeds, stir constantly, and ferment to obtain the fermentation material; (4), granulation: make the product obtained in step (4) into granules, then add pre-mixed enzyme-containing bentonite, and spray water Salicylic acid is enough;

Embodiment 3

[0022] Materials: soybean meal 31kg, corn husk 6kg, bran 6kg, phytase solution 16kg, bentonite 16kg, salicylic acid 11kg;

[0023] Production method: (1), purification and optimization of single colony seeds: coating single colony seeds on a petri dish with bacterial culture medium, and cultivating to obtain single colony seeds; (2), the single colony seeds obtained in step (1) After the colony seeds are fermented into first-level solid seeds, they are inoculated into the solid medium of the second-level fermenter to obtain second-level liquid seeds; (3), main ingredients for fermentation: three solid fermentation materials of soybean meal, corn bran and bran are put into fermentation In the pool, inoculate the secondary liquid seeds, stir constantly, and ferment to obtain the fermentation material; (4), granulation: make the product obtained in step (4) into granules, then add pre-mixed enzyme-containing bentonite, and spray water Salicylic acid is enough;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com