Metal organic coordination polymer coated natural sericin microsphere as well as preparation method and application thereof

A technology of coordination polymers and sericin, which is applied in the field of biomedical composite materials, can solve the problems of difficult control of the release rate of loaded drugs, difficulty of precise control of microsphere particle size, difficulty of controlling shape and size, etc., to achieve production High efficiency, low cost, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

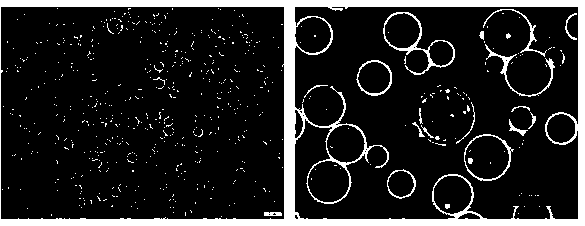

[0054] Example 1: Synthesis of natural sericin microspheres

[0055] (1) Wash and drain 20 g silkworm cocoons, soak them in 400 mL 0.02 mol / L Na 2 CO 3 In the solution, stir and heat reaction at 100°C and 600rpm for 1 hour, after cooling, centrifuge at 3500 rpm for 5 minutes to remove insoluble precipitates, take the upper clear solution and dialyze it in deionized water for 2-3 days with a 3500 Da dialysis bag, and the solution is dialyzed at 8000 rpm Centrifuge for 10 minutes to remove insoluble precipitates, take the upper clear solution, freeze it in liquid nitrogen, and place it in a vacuum freeze dryer to completely freeze-dry to obtain pure sericin solid;

[0056] (2) Prepare 1 mL of 10 wt% sericin solution, that is, dissolve 100 mg of sericin in 1 mL of deionized water, add it dropwise to corn oil containing 2% emulsifier Tween-20, The water-to-oil ratio is 1:10, that is, 10 mL of corn oil (containing emulsifier Tween-20 200 μL) is used, and emulsified at 800 rpm for...

Embodiment 2

[0062] Example 2: Effects of Different Concentrations of Sericin on the Synthesis of Sericin Microspheres

[0063] (1) Wash and drain 20 g silkworm cocoons, soak them in 400 mL 0.02 mol / L Na 2 CO 3 In the solution, stir and heat reaction at 100°C and 600rpm for 1 hour, after cooling, centrifuge at 3500 rpm for 5 minutes to remove insoluble precipitates, take the upper clear solution and dialyze it in deionized water for 2-3 days with a 3500 Da dialysis bag, and the solution is dialyzed at 8000 rpm Centrifuge for 10 minutes to remove insoluble precipitates, take the upper clear solution, freeze it in liquid nitrogen, and place it in a vacuum freeze dryer to completely freeze-dry to obtain pure sericin solid;

[0064] (2) Prepare 100 μL of 15 wt% sericin solution, that is, dissolve 15 mg sericin in 100 μL deionized water, add it dropwise to corn oil containing 2% emulsifier Tween-20, The water-to-oil ratio is 1:10, that is, the corn oil used is 1 mL (containing emulsifier Twee...

Embodiment 3

[0070] Example 3: Effects of different dosages of emulsifiers on the synthesis of sericin microspheres

[0071] (1) Wash and drain 20 g silkworm cocoons, soak them in 400 mL 0.02 mol / L Na 2 CO 3 In the solution, stir and heat reaction at 100°C and 600rpm for 1 hour, after cooling, centrifuge at 3500 rpm for 5 minutes to remove insoluble precipitates, take the upper clear solution and dialyze it in deionized water for 2-3 days with a 3500 Da dialysis bag, and the solution is dialyzed at 8000 rpm Centrifuge for 10 minutes to remove insoluble precipitates, take the upper clear solution, freeze it in liquid nitrogen, and place it in a vacuum freeze dryer to completely freeze-dry to obtain pure sericin solid;

[0072] (2) Prepare 100 μL of 10 wt% sericin solution, that is, dissolve 10 mg of sericin in 100 μL of deionized water, add it dropwise to corn oil containing 6% emulsifier Tween-20, The water-to-oil ratio is 1:10, that is, the corn oil used is 1 mL (containing emulsifier T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com