A kind of preparation method of sodium alginate/typha/graphene oxide composite airgel

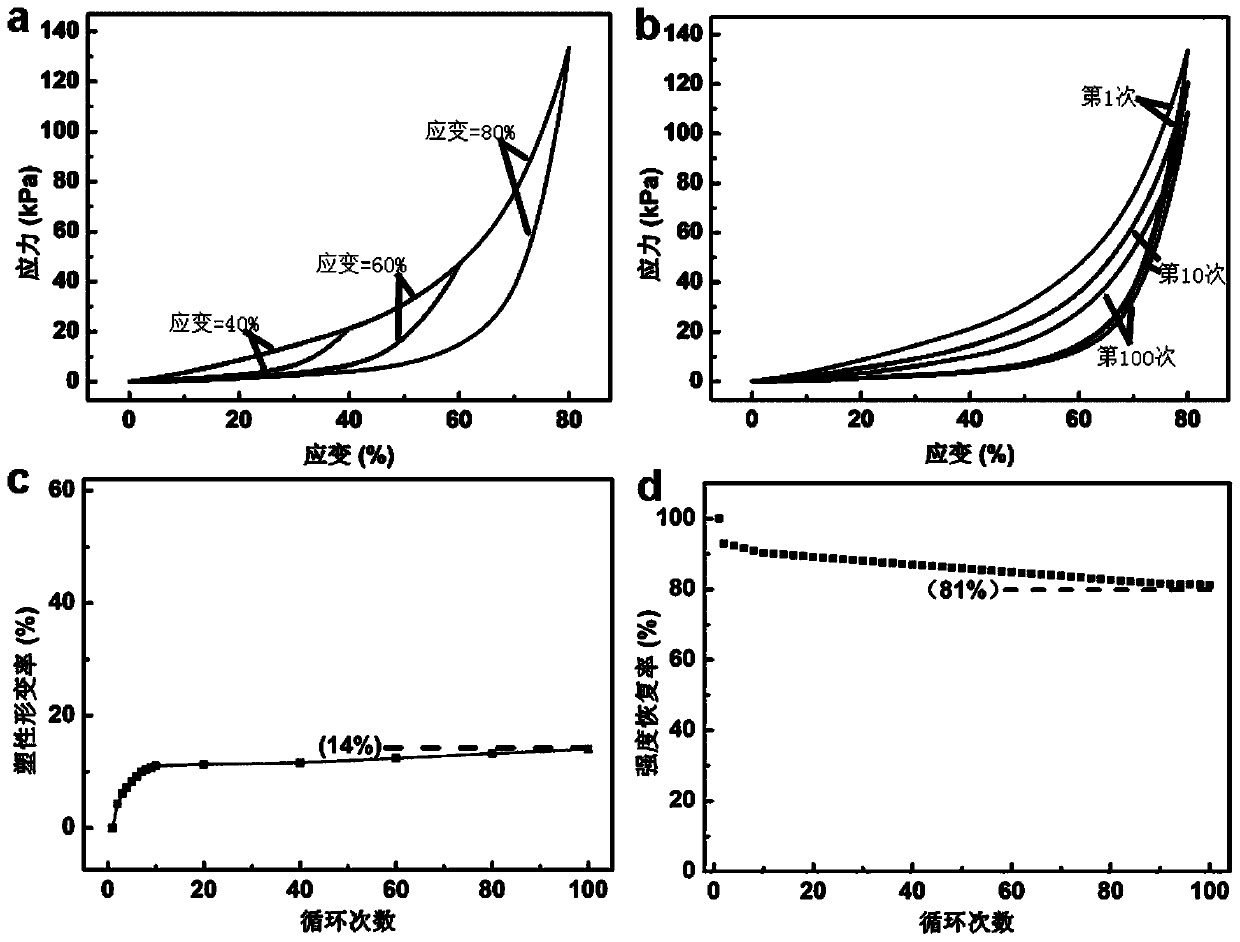

A graphene composite and composite airgel technology, which is applied in chemical instruments and methods, alkali metal compounds, water/sludge/sewage treatment, etc., can solve the problems of low mechanical strength and poor mechanical properties of biomass airgel , to achieve the effect of excellent mechanical properties, superior mechanical properties, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Prepare sodium alginate / typha / graphene oxide uniform mixed solution:

[0047] A. Preparation of graphene oxide dispersion: adding graphene oxide powder into deionized water, ultrasonic treatment for 2h, so that graphene oxide powder is evenly dispersed in deionized water, and a uniform graphene oxide dispersion is obtained;

[0048] B. Preparation of cattail fiber: First, wash 50 grams of cattail flower spikes in sequence with 1L of water and 1L of ethanol, add 4g of sodium chlorite and 400mL of deionized water into a flask equipped with a mechanical stirrer and a thermometer, and stir to fully dissolve them , adjust the pH of the sodium chlorite solution to 4.5 with 1.2 ml of acetic acid. Then add 4g of cattail flower spikes, stir at 1000rpm and 80°C for 2 hours, wash with deionized water to pH=6, then wash three times with absolute ethanol to remove residual water, and dry it in an oven at 60°C. Finally, dry cattail fibers are obtained.

[0049] C. Preparation o...

Embodiment 2

[0053] (1) Prepare sodium alginate / typha / graphene oxide uniform mixed solution:

[0054] A. Preparation of graphene oxide dispersion: adding graphene oxide powder into deionized water, ultrasonic treatment for 2h, so that graphene oxide powder is evenly dispersed in deionized water, and a uniform graphene oxide dispersion is obtained;

[0055] B. Preparation of cattail fiber: First, wash 50 grams of cattail flower spikes in sequence with 1L of water and 1L of ethanol, add 4g of sodium chlorite and 400mL of deionized water into a flask equipped with a mechanical stirrer and a thermometer, and stir to fully dissolve them , adjust the pH of the sodium chlorite solution to 4.5 with 1.2 ml of acetic acid. Then add 4g of cattail flower spikes, stir at 1000rpm and 80°C for 2 hours, wash with deionized water to pH=6, then wash three times with absolute ethanol to remove residual water, and dry it in an oven at 60°C. Finally, dry cattail fibers are obtained.

[0056] C. Preparation o...

Embodiment 3

[0060] (1) Prepare sodium alginate / typha / graphene oxide uniform mixed solution:

[0061] A. Preparation of graphene oxide dispersion: adding graphene oxide powder into deionized water, ultrasonic treatment for 3h, so that graphene oxide powder is evenly dispersed in deionized water, and a uniform graphene oxide dispersion is obtained;

[0062] B. Preparation of cattail fiber: First, wash 50 grams of cattail flower spikes in sequence with 1L of water and 1L of ethanol, add 4g of sodium chlorite and 400mL of deionized water into a flask equipped with a mechanical stirrer and a thermometer, and stir to fully dissolve them , adjust the pH of the sodium chlorite solution to 4.5 with 1.2 ml of acetic acid. Then add 4g of cattail flower spikes, stir at 1000rpm and 80°C for 2 hours, wash with deionized water to pH=6, then wash three times with absolute ethanol to remove residual water, and dry it in an oven at 60°C. Finally, dry cattail fibers are obtained.

[0063] C. Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com