Graphitized mesoporous carbon-TiO2 composite photocatalytic material as well as preparation method and application thereof

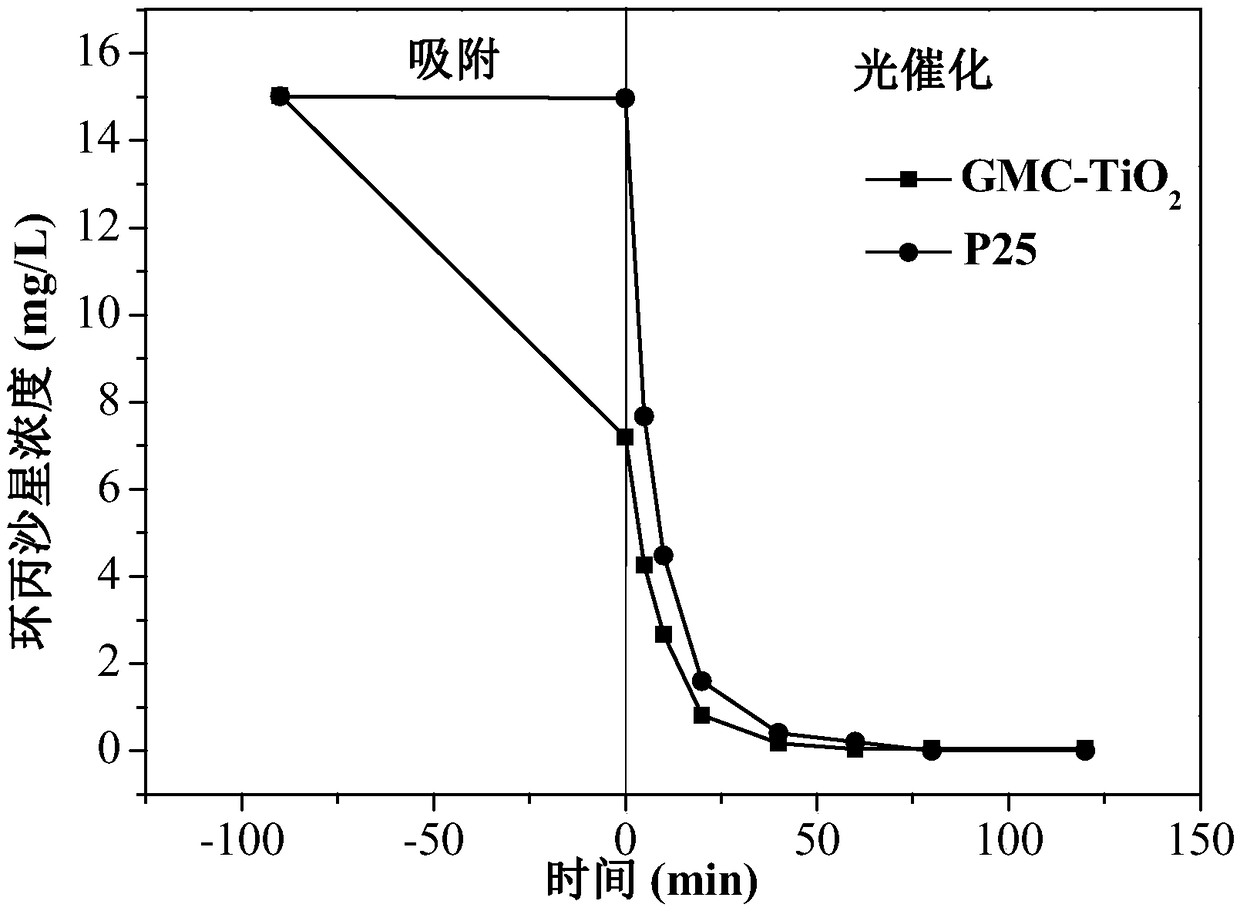

A technology of composite photocatalysis and photocatalytic materials, which is applied in the field of nanocomposite materials, can solve the problems of complex carbon fiber pretreatment process and unclear antibiotic wastewater treatment effect, and achieve efficient removal, improved photocatalytic performance, and good electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A GMC-TiO 2 The preparation method of composite photocatalytic material comprises steps as follows:

[0047] (1) Dissolve F127 in water and absolute ethanol with a volume ratio of 1:1 at room temperature and constant stirring, and control its mass concentration to 0.06%. After the reagent is completely dissolved, add resorcinol in sequence , concentrated HCl and formaldehyde solution, control the molar ratio of resorcinol and formaldehyde to be 1:2, and the pH of the solution is 1.5 to obtain solution A; the mass ratio of F127 to quinone is 1:1;

[0048] (2) Under the condition of room temperature and continuous stirring, put the titanium trichloride solution (containing 3wt% hydrochloric acid) with a concentration of 0.5mol / L in water, control its volume ratio to 1:1, stir for a period of time and then Join NaNO 3 , Na 2 SO 4 , respectively controlling the volume ratio of its quality to the aqueous solution of titanium trichloride to be 1:80g / mL and 1:60g / mL, and c...

Embodiment 2

[0054] A GMC-TiO 2 The preparation method of composite photocatalytic material comprises steps as follows:

[0055] (1) Dissolve F127 in water and absolute ethanol with a volume ratio of 1:2 at room temperature and constant stirring, and control its mass concentration to 0.08%. After the reagent is completely dissolved, add resorcinol in sequence , concentrated HCl and formaldehyde solution, control the molar ratio of resorcinol and formaldehyde to be 1:3, and the pH of the solution is 1.0 to obtain solution A; the mass ratio of F127 to quinone is 2:1;

[0056] (2) Under the condition of room temperature and continuous stirring, put the titanium trichloride solution (containing 3wt% hydrochloric acid) with a concentration of 0.1mol / L in water, control its volume ratio to 1:2, and then stir for a period of time Join NaNO 3 , Na 2 SO 4 , respectively controlling the volume ratio of its quality to the aqueous solution of titanium trichloride to be 1:70g / mL and 1:50g / mL, and c...

Embodiment 3

[0061] A GMC-TiO 2 The preparation method of composite photocatalytic material comprises steps as follows:

[0062] (1) Dissolve F127 in water and absolute ethanol with a volume ratio of 1:4 at room temperature and under constant stirring, and control its mass concentration to 0.1%. After the reagent is completely dissolved, add resorcinol in sequence , concentrated HCl and formaldehyde solution, the control resorcinol and formaldehyde molar ratio is 1:5, the pH of solution is 3.0, obtains solution A; The mass ratio of F127 and hydroquinone is 1.5:1;

[0063] (2) Under the condition of room temperature and constant stirring, put the titanium trichloride solution (containing 3wt% hydrochloric acid) with a concentration of 1.5mol / L in water, control its volume ratio to 1:4, stir for a period of time and then sequentially Join NaNO 3 , Na 2 SO 4 , respectively controlling the volume ratio of its quality to the aqueous solution of titanium trichloride to be 1:90g / mL and 1:70g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com