A high-strength, wear-resistant superhydrophobic composite material and its preparation method

A composite material and super-hydrophobic technology, which is applied in the field of super-hydrophobic composite materials, can solve the problems of super-hydrophobic materials losing their use value and improving the wear resistance of super-hydrophobic properties. The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Mix 3.0 mL of ethyl orthosilicate, 3.5 mL of hexamethyldisilazane, and 30 mL of ethanol, stir at room temperature for 40 min, then add 5 mL of deionized water, and continue stirring for 3 h to obtain a hydrophobic silica sol;

[0052] (2) Take by weighing 0.70g of bisphenol A epoxy resin, 0.30g of curing agent, 12g of silica sol, join in the beaker, heat until epoxy resin and curing agent all dissolve, obtain uniform epoxy resin mixture;

[0053] (3) Cut the ultrasonically cleaned and dried latex sponge into a size of 10mm*10mm*5mm, add it to the epoxy resin mixture, and react at 35°C and 300rpm stirring speed for 24h;

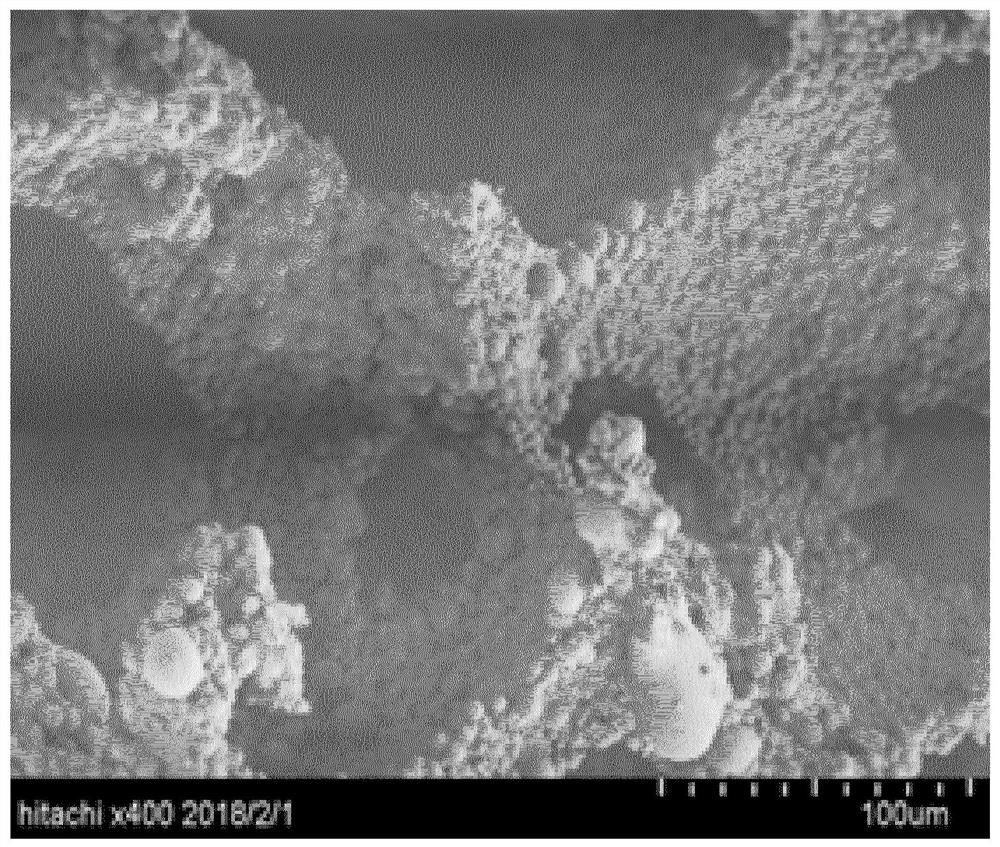

[0054] (4) Take out the reacted sponge, put it in an oven at 60°C, move the sponge in a random direction every 1 hour, and dry it for 6 hours to obtain a block-shaped wear-resistant superhydrophobic material with high hardness;

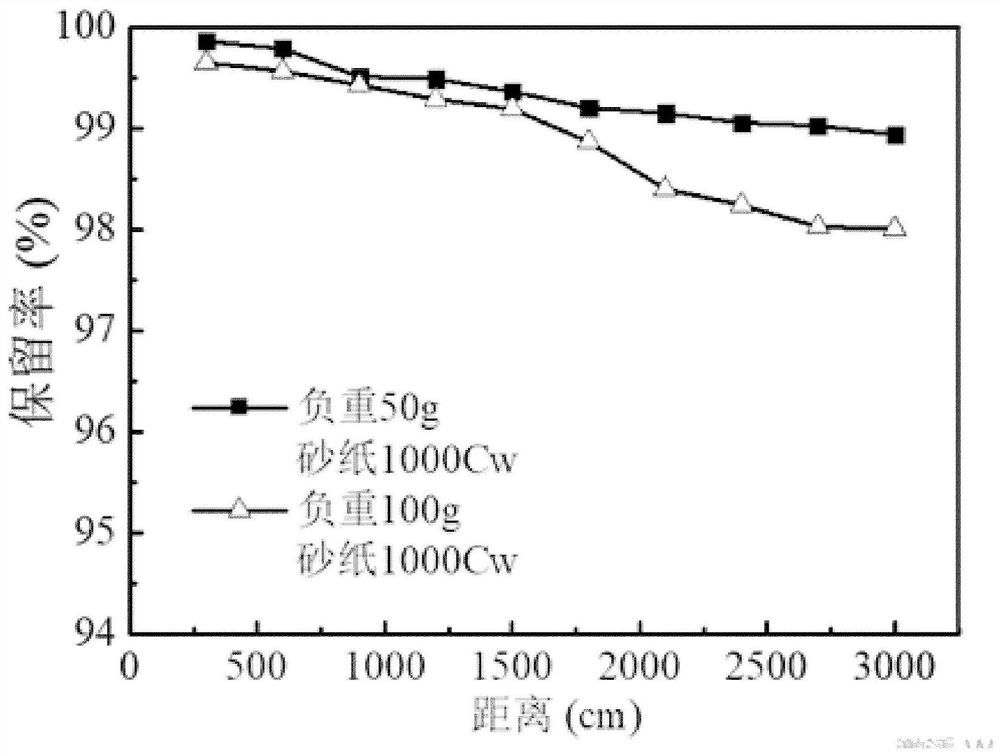

[0055] After the above drying, a block material with high hardness can be obtained, with a contact angle of 158.8° and a ...

Embodiment 2

[0057] (1) Mix 2.5 mL of ethyl orthosilicate, 5.0 mL of hexamethyldisilazane, and 30 mL of ethanol, stir at room temperature for 40 min, then add 5 mL of deionized water, and continue stirring for 3 h to obtain a hydrophobic silica sol;

[0058] (2) Take by weighing 0.85g of bisphenol F epoxy resin, 0.35g of curing agent, 16g of silica sol, join in the beaker, heat until epoxy resin and curing agent all dissolve, obtain uniform epoxy resin mixture;

[0059] (3) Cut the ultrasonically cleaned and dried polyurethane sponge into a size of 10mm*10mm*5mm, add it to the epoxy resin mixture, and react at 35°C and 300rpm stirring speed for 24h;

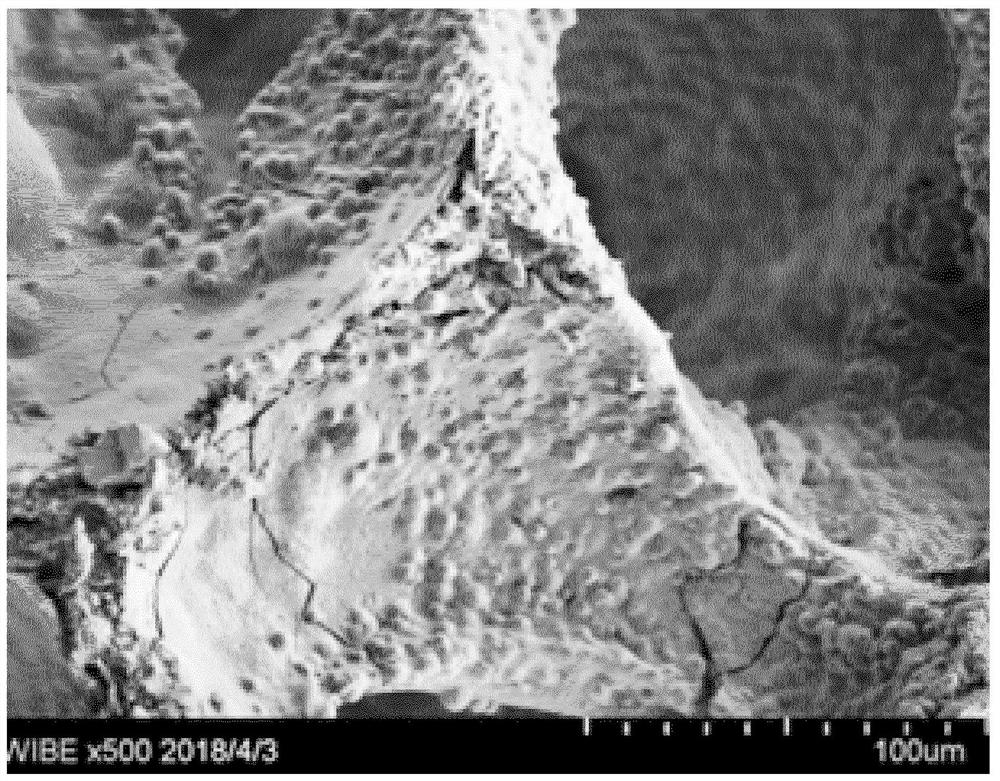

[0060] (4) Place the reacted polyurethane on a glass sheet, put it in an oven at 60°C, and let it dry for 6 hours. After curing, a wear-resistant superhydrophobic block material firmly bonded to the substrate is obtained.

[0061] After the above drying, a high-hardness wear-resistant bulk material firmly bonded to the substrate can be obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com