Superamphiphobic self-cleaned fluorosilicone coating material and preparation method thereof

A coating material and super-amphiphobic technology, applied in coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of high cost, many types of raw materials, and few types of applicable substrates, and the preparation method is simple. , Stable anti-wetting, high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Step 1, prepare fluorosilicone amphiphobic treatment agent

[0057] 1.1 Measure 0.016ml 3-aminopropyltrimethoxysilane and 0.026ml hexafluorocyclopropane trimer respectively;

[0058] 1.2 At room temperature, in a nitrogen environment, first add the 3-aminopropyltrimethoxysilane measured in step 1.1 into the reaction flask, and then slowly dissolve the hexafluorocyclopropane trimer measured in step 1.1 under magnetic stirring Add dropwise to the flask. The reaction was carried out for 6 hours at room temperature in a nitrogen atmosphere to obtain the fluorosilicone amphoteric treatment agent.

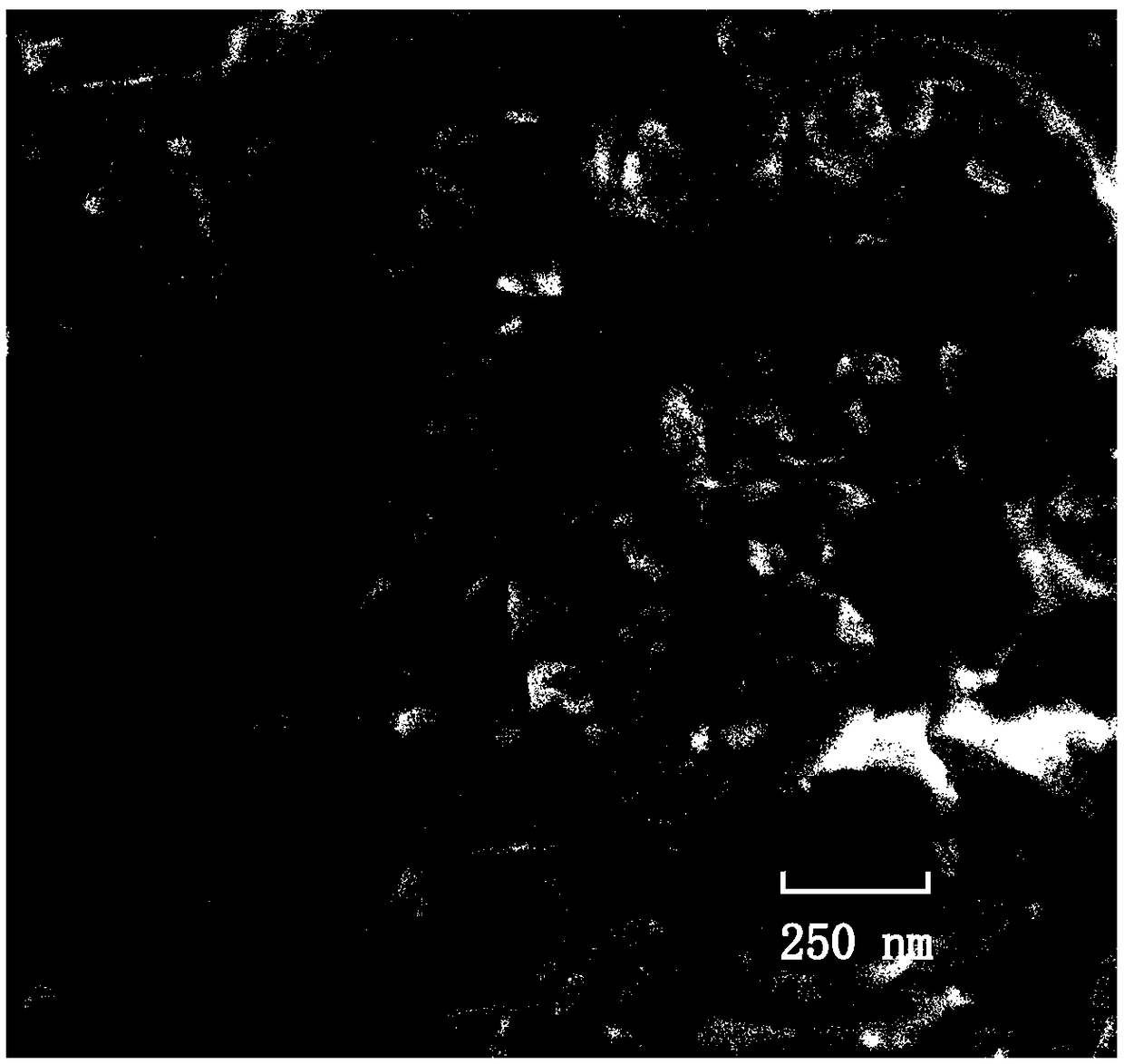

[0059] Step 2, configure super-amphiphobic, self-cleaning fluorosilicon coating material

[0060] The reaction product of step 1 was collected and dispersed into 6.40 ml of isopropanol under magnetic stirring to prepare a coating material with a concentration of 1%. The percentages are mass ratios.

[0061] Step 3, using coating materials to prepare superamphiphobic, self-clea...

Embodiment 2

[0065] Step 1, prepare fluorosilicone amphiphobic treatment agent

[0066] 1.1 Measure 0.016ml of 3-aminopropyltriethoxysilane coupling agent and 0.019ml of hexafluorooxypropane trimer respectively;

[0067] 1.2 At room temperature, in a nitrogen environment, add the 3-aminopropyltriethoxysilane measured in step 1.1 into the reaction flask, and under magnetic stirring, add the hexafluoropropylene oxide trimer measured in step 1.1 Slowly add dropwise to the flask. The reaction was carried out at room temperature and nitrogen environment for 8 hours to obtain the fluorosilicone amphoteric treatment agent.

[0068] Step 2, configure super-amphiphobic, self-cleaning fluorosilicon coating material

[0069] The reaction product of step 1 was collected and dispersed into 10.00 ml of isopropanol under magnetic stirring to prepare a coating material with a concentration of 0.05%. The percentages are mass ratios.

[0070] Step 3, using coating materials to prepare superamphiphobic, ...

Embodiment 3

[0074] Step 1, prepare fluorosilicone amphiphobic treatment agent

[0075] 1.1 Measure 0.010ml 3-aminopropyltriethoxysilane and 0.012ml hexafluorooxypropane trimer respectively;

[0076] 1.2 At room temperature, in a nitrogen environment, first add the 3-aminopropyltriethoxysilane weighed in step 1.1 into the reaction flask, and then add the hexafluorocyclopropane trimer weighed in step 1.1 under magnetic stirring Slowly add dropwise to the flask. The reaction was carried out at room temperature in a nitrogen atmosphere for 8 hours to obtain the fluorosilicone amphoteric treatment agent.

[0077] Step 2, configure super-amphiphobic, self-cleaning fluorosilicon coating material

[0078] The reaction product of step 1 was collected and dispersed into 3.20 ml of isopropanol under magnetic stirring to prepare a coating material with a concentration of 1%. The percentages are mass ratios.

[0079] Step 3, using coating materials to prepare superamphiphobic, self-cleaning fluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

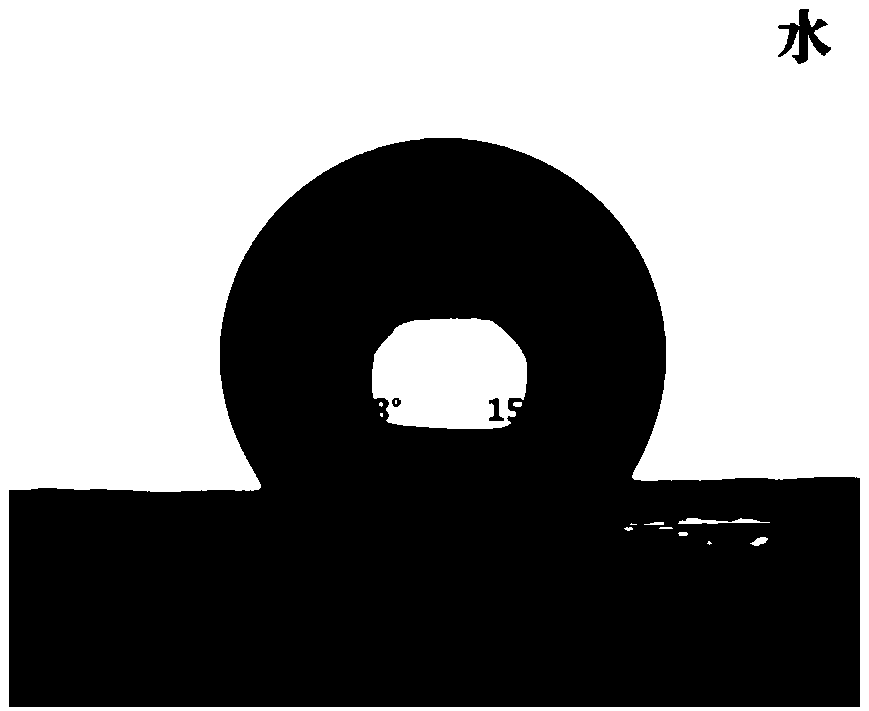

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com