Amorphous alloy polishing solution and amorphous alloy polishing method

A technology of amorphous alloy and polishing fluid, applied in the field of amorphous alloy polishing, can solve the problems of chemical residue, difficult cleaning, high free electron content, etc., and achieve the effect of low current density, guaranteed polishing quality, and low atomic momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

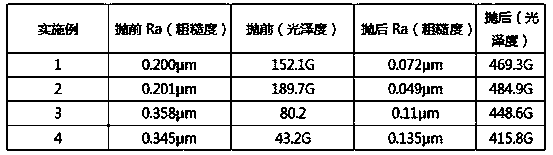

Embodiment 1

[0019] A method for polishing an amorphous alloy, comprising the steps of:

[0020] (1) Sample cleaning: use an ultrasonic machine to clean and dry the surface of the amorphous alloy sample, wherein the composition of the amorphous alloy sample is Zr-Cu-Al-Ni-Ti, and its ratio is Zr30 .1:: Cu11.19: Ni10.77: Ti2.22: Al4.81;

[0021] (2) Preparation of polishing liquid: Prepare 1L of polishing liquid with deionized water as solvent. In the polishing liquid, the content of each component is: ammonium sulfate 60g / L, ammonium bifluoride 0.5g / L, sodium sulfite 1.5g / L, molybdenum Ammonium acid 0.5g / L, sodium dodecylsulfobenzenesulfonate 0.5g / L;

[0022] (3) Take the zirconium-based amorphous alloy sample as the anode and connect it to the positive pole of the DC power supply and immerse it in the tank containing the electrolyte polishing solution prepared in step (2);

[0023] (4) Take the stainless steel sheet as the cathode and connect it to the negative pole of the DC power supp...

Embodiment 2

[0028] A method for polishing an amorphous alloy, comprising the steps of:

[0029] (1) Sample cleaning: use an ultrasonic machine to clean and dry the surface of the amorphous alloy sample, wherein the composition of the amorphous alloy sample is Zr-Cu-Al-Ni-Ti, and its ratio is Zr30 .1:: Cu11.19: Ni10.77: Ti2.22: Al4.81;

[0030] (2) Preparation of polishing liquid: prepare 1L of polishing liquid with deionized water as solvent. In the polishing liquid, the content of each component is: ammonium sulfate 30g / L, ammonium bifluoride 1.5g / L, sodium sulfite 1.8g / L, molybdenum Ammonium acid 1g / L, sodium dodecyl sulfobenzene sulfonate 1g / L;

[0031] (3) Take the zirconium-based amorphous alloy sample as the anode and connect it to the positive pole of the DC power supply and immerse it in the tank containing the electrolyte polishing solution prepared in step (2);

[0032] (4) Take the copper sheet as the cathode and connect it to the negative pole of the DC stabilized power supp...

Embodiment 3

[0037] A method for polishing an amorphous alloy, comprising the steps of:

[0038] (1) Sample cleaning: use an ultrasonic machine to clean and dry the surface of the amorphous alloy sample, wherein the composition of the amorphous alloy sample is Zr-Cu-Al-Ni-Ti, and its ratio is Zr30 .1:: Cu11.19: Ni10.77: Ti2.22: Al4.81;

[0039] (2) Preparation of polishing liquid: Prepare 1L of polishing liquid with deionized water as solvent. In the polishing liquid, the content of each component is: ammonium chloride 50g / L, ammonium bifluoride 2g / L, sodium sulfite 3g / L, molybdic acid Ammonium 1.2g / L, sodium dodecasulfobenzenesulfonate 1g / L;

[0040] (3) Take the zirconium-based amorphous alloy sample as the anode and connect it to the positive pole of the DC power supply and immerse it in the tank containing the electrolyte polishing solution prepared in step (2);

[0041] (4) The graphite sheet is used as the cathode to be connected to the negative pole of the DC stabilized power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com