Organic light emitting diode containing multi-level organic semiconductor heterojunction

A technology for organic semiconductors and light-emitting diodes, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., which can solve the problems of commercialization and popularization of the preparation of high-performance organic light-emitting diodes, the distance from application is too large, and the crystallization conditions are harsh. and other problems, to achieve the effect of simplifying the structure and preparation process, efficient hole and electron transport characteristics, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

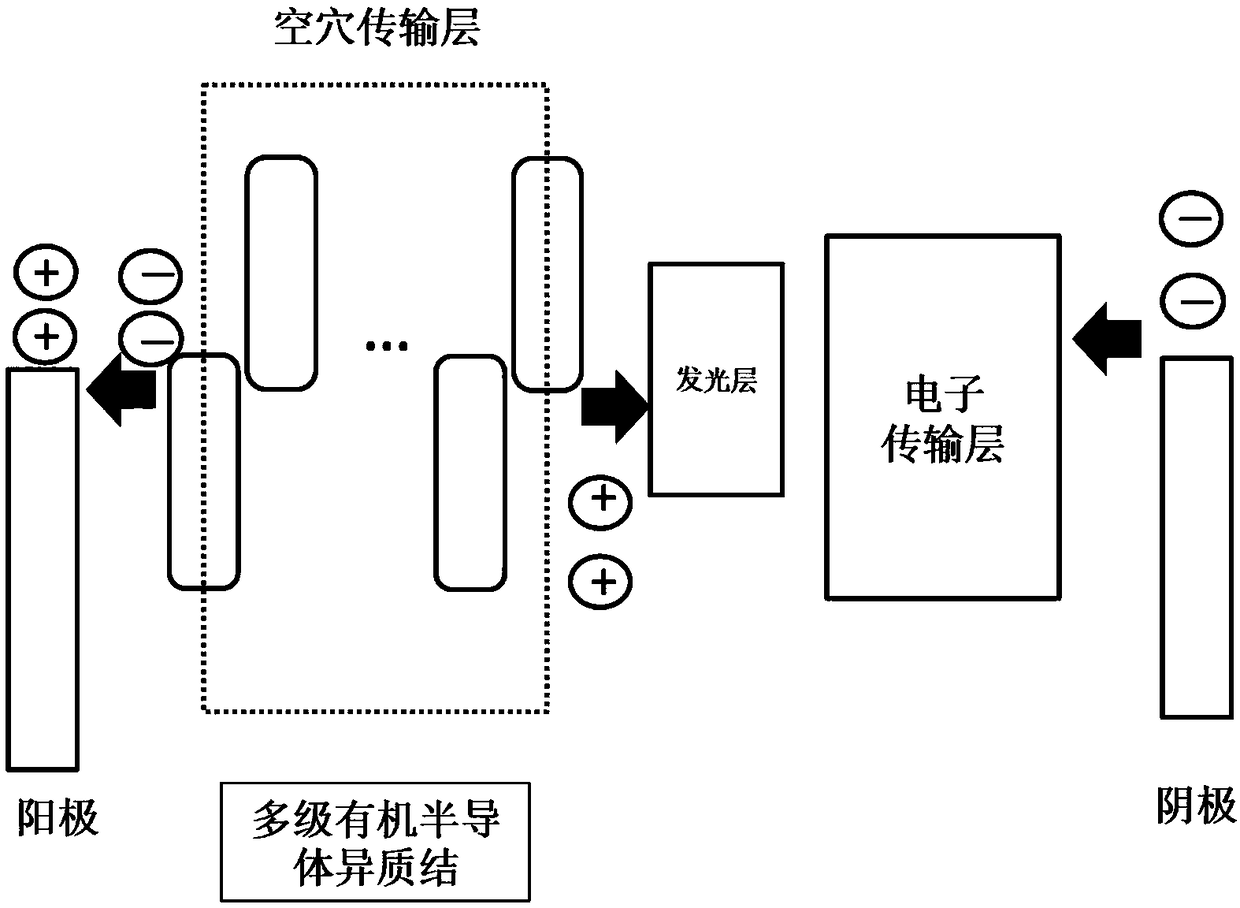

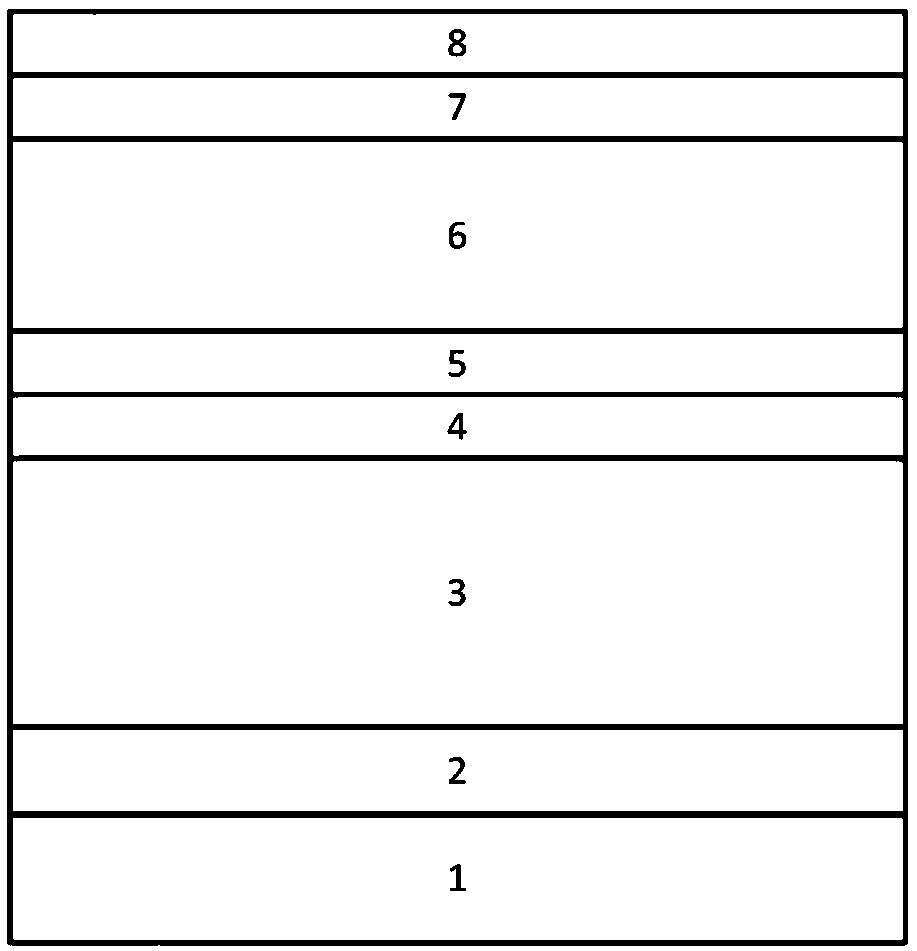

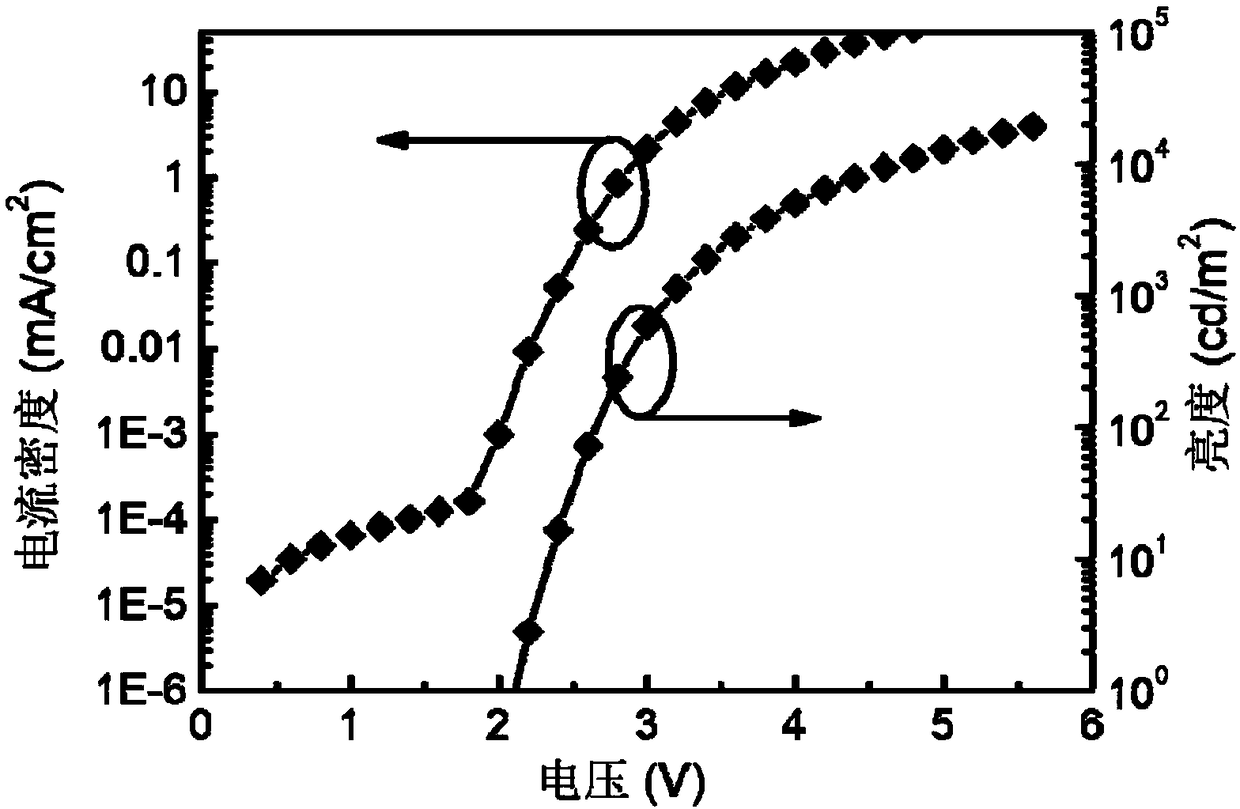

[0039] An organic light-emitting diode device using a multi-level organic semiconductor heterojunction as a hole transport layer in this embodiment, the schematic diagram of its working principle is as follows figure 1 As shown, the schematic diagram of its stacked structure is shown in figure 2 As shown, the substrate 1, anode 2, multi-level organic semiconductor heterojunction hole transport layer 3, light emitting layer 4, hole / exciton blocking layer 5, electron transport layer 6, electron injection layer 7 and Cathode 8 composition. It is prepared by the following method:

[0040] First, the ITO layer 2 of the substrate glass layer 1 is photolithographically formed into thin strip electrodes, then cleaned with lotion and rinsed with a large amount of deionized water, blown dry with nitrogen, and baked in a blast oven at 120 degrees for 20 minute. After drying, after 15 minutes of ultraviolet ozone treatment, it is directly transferred to the vacuum coating system until...

Embodiment 2

[0043] In this embodiment, an organic light-emitting diode device using a multi-level organic semiconductor heterojunction as a hole transport layer and an electron transport layer at the same time, the schematic diagram of its working principle is as follows Figure 8 As shown, the schematic diagram of its stacked structure is shown in Figure 9 As shown, the substrate 1, the anode 2, the multi-level organic semiconductor heterojunction hole transport layer 3, the light-emitting layer 4, the hole / exciton blocking layer 5, the electron injection layer 6, the multi-level organic semiconductor heterojunction stacked in sequence The mass junction electron transport layer 7 and the cathode 8 are composed. It is prepared by the following method:

[0044] First, the ITO layer 2 of the substrate glass layer 1 is photolithographically formed into thin strip electrodes, then cleaned with lotion and rinsed with a large amount of deionized water, blown dry with nitrogen, and baked in a ...

Embodiment 3

[0047] In this embodiment, an organic light-emitting diode device using a multi-level organic semiconductor heterojunction as a hole transport layer, an electron transport layer, and a charge generation layer at the same time, the schematic diagram of its working principle is as follows Figure 15 As shown, the schematic diagram of its stacked structure is shown in Figure 16 As shown, the substrate 1, the anode 2, the multi-level organic semiconductor heterojunction hole transport layer 3, the light-emitting layer 4, the hole / exciton blocking layer 5, the electron injection layer 6, the multi-level organic semiconductor heterojunction stacked in sequence It consists of a mass junction charge generation layer 7 , a light emitting layer 8 , a hole / exciton blocking layer 9 , an electron injection layer 10 , a multilevel organic semiconductor heterojunction electron transport layer 11 and a cathode 12 . It is prepared by the following method:

[0048] First, the ITO layer 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com