Method for preparing organic luminous device with red light

An organic light-emitting device, red light technology, applied in chemical instruments and methods, light-emitting materials, electroluminescent light sources, etc., can solve the problems of concentration quenching and weakness of organic small molecule red light materials, achieve stable light emission, overcome the concentration The effect of quenching, efficient hole transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

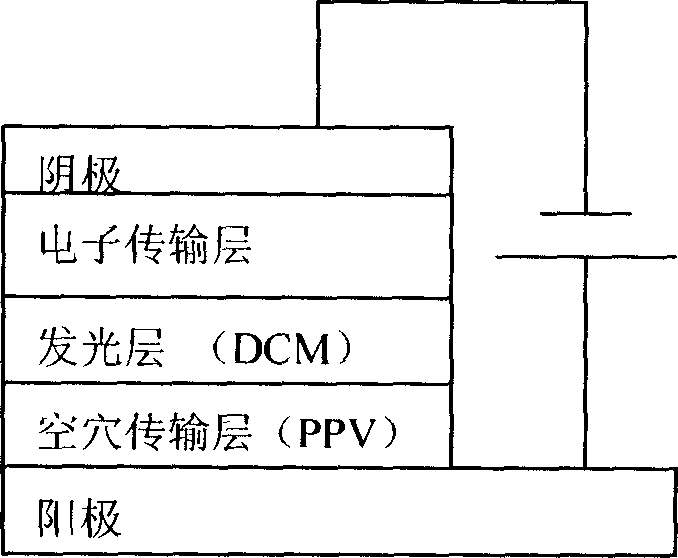

[0031] The preparation method of the organic light-emitting device of the invention is to prepare a hole transport layer, a light-emitting layer and an electron transport layer between the anode and the cathode. Specific steps are as follows:

[0032] 1. Anode:

[0033] The anode of the device is ITO (indium tin oxide) on a glass substrate, which can be purchased commercially. The anode material can also be selected from a variety of metal materials, and the work function of the material is suitable for greater than or equal to 4eV. Examples of such materials include carbon, aluminum, silver, gold, iron, cobalt, nickel, platinum, vanadium, palladium, and Alloys of these metals, but electrode materials are not limited to those exemplified. The preparation method of the anode layer can adopt methods such as vacuum vapor deposition and magnetron sputtering.

[0034] 2. Hole transport layer:

[0035] The hole-transporting material is poly-p-phenylene vinylene (PPV) or a deriva...

Embodiment approach

[0078] (1) anode

[0079] The anode is commercially purchased ITO glass, which is washed with detergent in deionized water for 30 minutes, then washed in acetone and ethanol for 15 minutes respectively, soaked in methanol, and the ITO glass is taken out of methanol, and the methanol is blown dry with nitrogen flow , and fixed on the base plate of the homogenizer.

[0080] (2) Hole transport layer

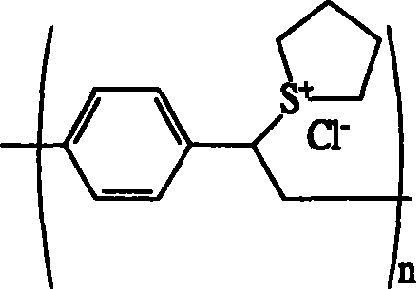

[0081] The mass percent concentration is 0.61% poly-p-phenylene vinylene (PPV) prepolymer methanol solution to cover the ITO glass, the molecular structure of the poly-p-phenylene vinylene prepolymer is as follows:

[0082]

[0083] Rotate at a speed of 3000rpm / s for 30 seconds to form a poly-p-phenylene vinylene (PPV) prepolymer film on the ITO glass, and heat the ITO glass at 160°C for 2 hours in a vacuum to obtain partially conjugated poly-p-phenylene Vinylene, the molecular structure is as follows:

[0084]

[0085] (3) Light-emitting layer

[0086] The obtained ITO gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com