P-type doped material based on triaryl boron-nitrogen skeleton and preparation method and application thereof

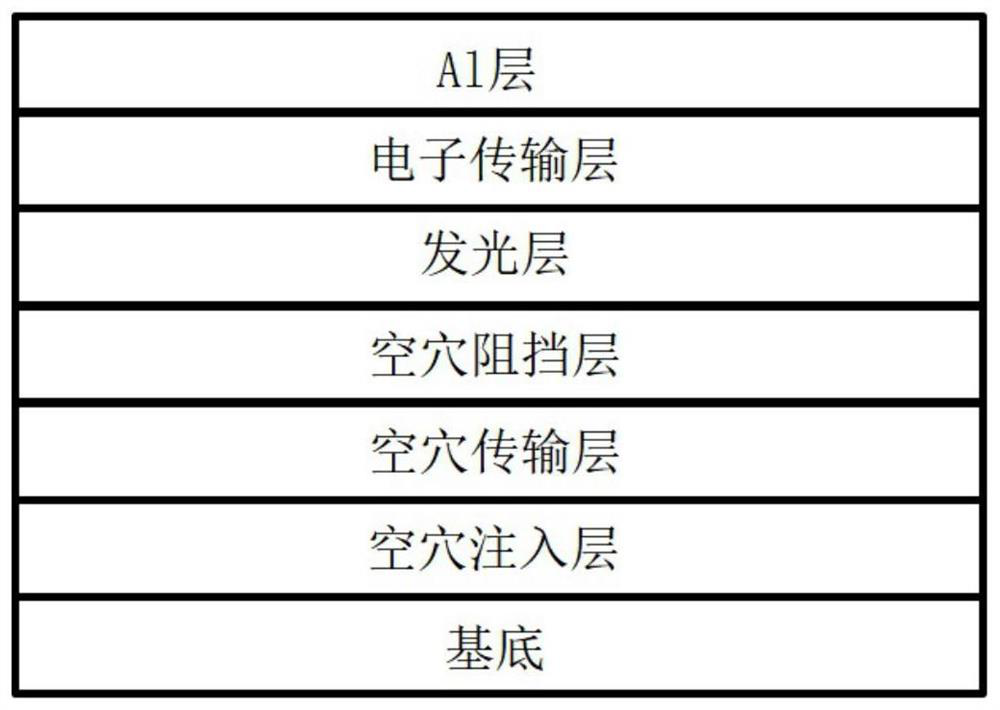

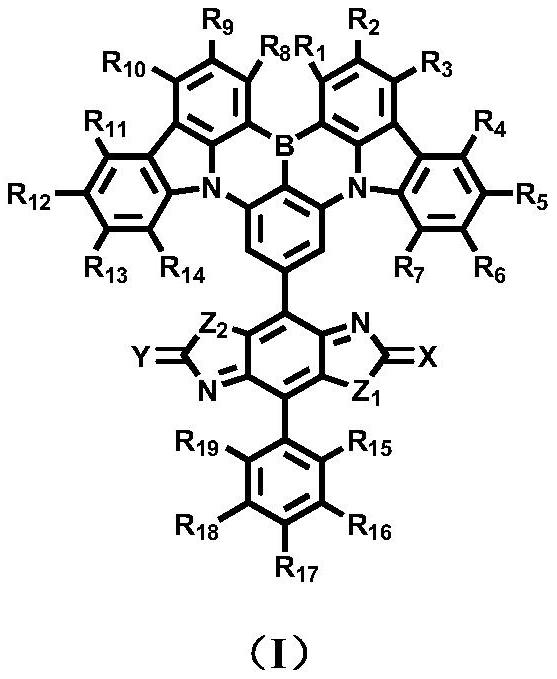

A technology of triaryl boron nitrogen and doping materials, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, compounds containing elements of Group 3/13 of the periodic table, etc., and can solve the shortage of high-efficiency P-type dopant materials , low luminous efficiency, fast aging speed and other problems, to achieve the effect of enhancing hole injection ability, improving luminous efficiency, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

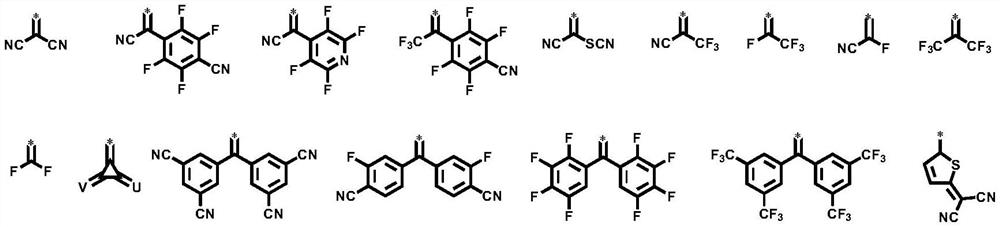

Embodiment 1

[0139] Preparation of compound 2

[0140] The chemical synthesis reaction scheme is as follows:

[0141]

[0142] Synthesis of Intermediate S1: A mixture of ethyl orthoformate (22.20 g, 150 mmol), yttrium trifluoromethanesulfonate (1.30 g, 2.5 mmol) and 100 mL of dimethyl sulfoxide was heated to 60 °C in batches and (about 0.50g each time, added within 10min) add 3,6-diamino-2,5-dibromo-1,4-hydroquinone (14.90g, 50mmol), stir overnight at 60°C, then cool to room temperature And dilute with water. The resulting precipitate was collected by filtration and washed with distilled water and cold ethanol, yield 75%. Molecular formula C 8 h 2 Br 2 N 2 O 2 , ESI(H + ): 316.8566.

[0143] Synthesis of Intermediate 2-1: Intermediate S1 (6.36g, 20mmol), p-fluorophenylboronic acid (3.08g, 22mmol), 300mL toluene and 80mL water mixture, add catalyst tetrakis (triphenylphosphine) palladium (0.12g , 0.1 mmol) and potassium carbonate (4.16 g, 30 mmol). The system was heated to ref...

Embodiment 2

[0151] Preparation of compound 12

[0152] The chemical synthesis reaction scheme is as follows:

[0153]

[0154] Synthesis of Intermediate 12-1: According to the synthesis of Intermediate 2-1, an equimolar amount of 2,4,6-trifluorophenylboronic acid was substituted for p-fluorophenylboronic acid, and the yield was 70%. Molecular formula C 14 H 4 BrF 3 N 2 O 2 , ESI(H + ): 368.9482.

[0155] Synthesis of Intermediate 12-2: According to the synthesis of Intermediate 2-2, intermediate 2-1 was replaced with an equimolar amount of Intermediate 12-1, and the yield was 82%. Molecular formula C 14 H 6 BF 3 N 2 O 4 , ESI(H + ): 335.0449.

[0156] Synthesis of Intermediate 12-3: According to the synthesis of Intermediate 2-4, intermediate 2-2 was replaced with an equimolar amount of Intermediate 12-2, and the yield was 68%. Molecular formula C 44 H 18 ClF 7 N 4 O 2 , MALDI-TOF (m / z): 802.23.

[0157] Synthesis of intermediate 12-4: According to the synthesis of...

Embodiment 3

[0161] Preparation of Compound 13

[0162] The chemical synthesis reaction scheme is as follows:

[0163]

[0164] Synthesis of Intermediate 13-1: According to the synthesis of Intermediate 2-1, an equimolar amount of 3,4,5-trifluorophenylboronic acid was substituted for p-fluorophenylboronic acid, and the yield was 68%. Molecular formula C 14 H 4 BrF 3 N 2 O 2 , ESI(H + ): 368.9484.

[0165] Synthesis of Intermediate 13-2: According to the synthesis of Intermediate 2-2, intermediate 2-1 was replaced with an equimolar amount of Intermediate 13-1, and the yield was 84%. Molecular formula C 14 H 6 BF 3 N 2 O 4 , ESI(H + ): 335.0452.

[0166] Synthesis of Intermediate 13-3: According to the synthesis of Intermediate 2-4, intermediate 2-2 was replaced with an equimolar amount of Intermediate 13-2, and the yield was 70%. Molecular formula C 44 H 18 ClF 7 N 4 O 2 , MALDI-TOF (m / z): 802.16.

[0167] Synthesis of Intermediate 13-4: According to the synthesis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com