A kind of narrow bandgap black zirconia nanotube thin film and preparation method thereof

A technology of zirconia and nanotubes, which is applied in the field of narrow bandgap black zirconia nanotube films and its preparation, can solve problems such as limitations, and achieve the effects of improving absorption performance, reducing bandgap width, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

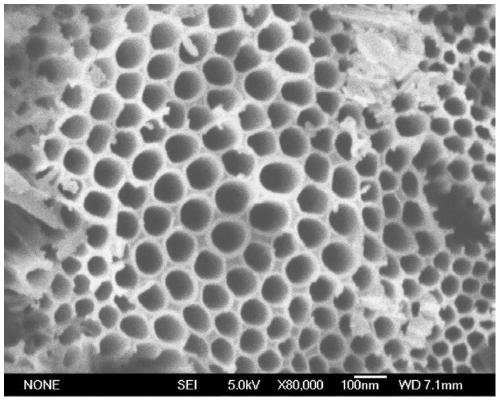

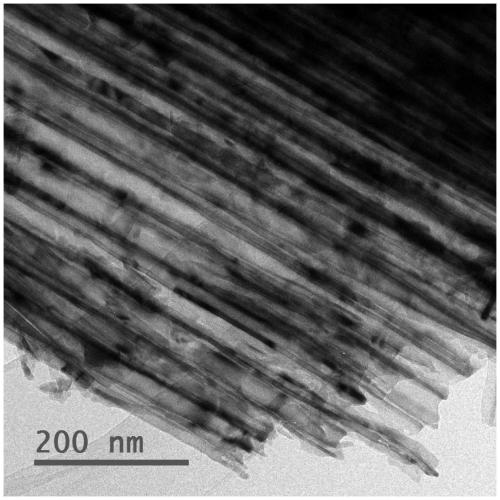

[0042] Embodiment 1: the preparation of zirconia nanotube film

[0043] (1) Select a zirconium sheet with a diameter of 23 mm to be mechanically polished to a mirror surface as an anodic oxidation raw material;

[0044] (2) Add 0vol% hydrofluoric acid (analytical pure, 40%), 0.35mol / L ammonium fluoride, 1vol% deionized water to glycerol (analytical pure, 99%), stir evenly, as anode Oxidation electrolyte A is stand-by; In glycerol (analytical pure, 99%), add the hydrofluoric acid (analytical pure, 40%) of 0vol%, the ammonium fluoride of 0.35mol / L, 10vol% deionized water, stir Uniform, as the anodic oxidation electrolyte B stand-by.

[0045] (3) A two-electrode system is adopted, the graphite sheet is used as the cathode, and the zirconium sheet is used as the anode, and the anodic oxidation is carried out in the electrolyte solution A and the electrolyte solution B respectively. Constant temperature 25 ℃, supplemented by magnetic stirring electrolyte for anodic oxidation prep...

Embodiment 2

[0048] Embodiment 2: Preparation of narrow bandgap black zirconia nanotube film

[0049] (1) Select a zirconium sheet with a diameter of 23 mm to be mechanically polished to a mirror surface as an anodic oxidation raw material;

[0050] (2) Add 2vol% hydrofluoric acid (analytically pure, 40%) in glycerol (analytical pure, 99%), the ammonium fluoride (solid) of 0.35mol / L, 2.5vol% deionized water, stir Uniform, as anodizing electrolyte.

[0051] (3) A two-electrode system is adopted, graphite sheet is used as cathode, zirconium sheet is used as anode, DC power supply is constant voltage 50V, constant temperature is 25°C, supplemented by magnetic stirring electrolyte for anodic oxidation preparation, and the duration is 2h.

[0052] (4) Rinse the anodized zirconia nanotube film prepared above with deionized water, and dry at 80° C. for 2 hours.

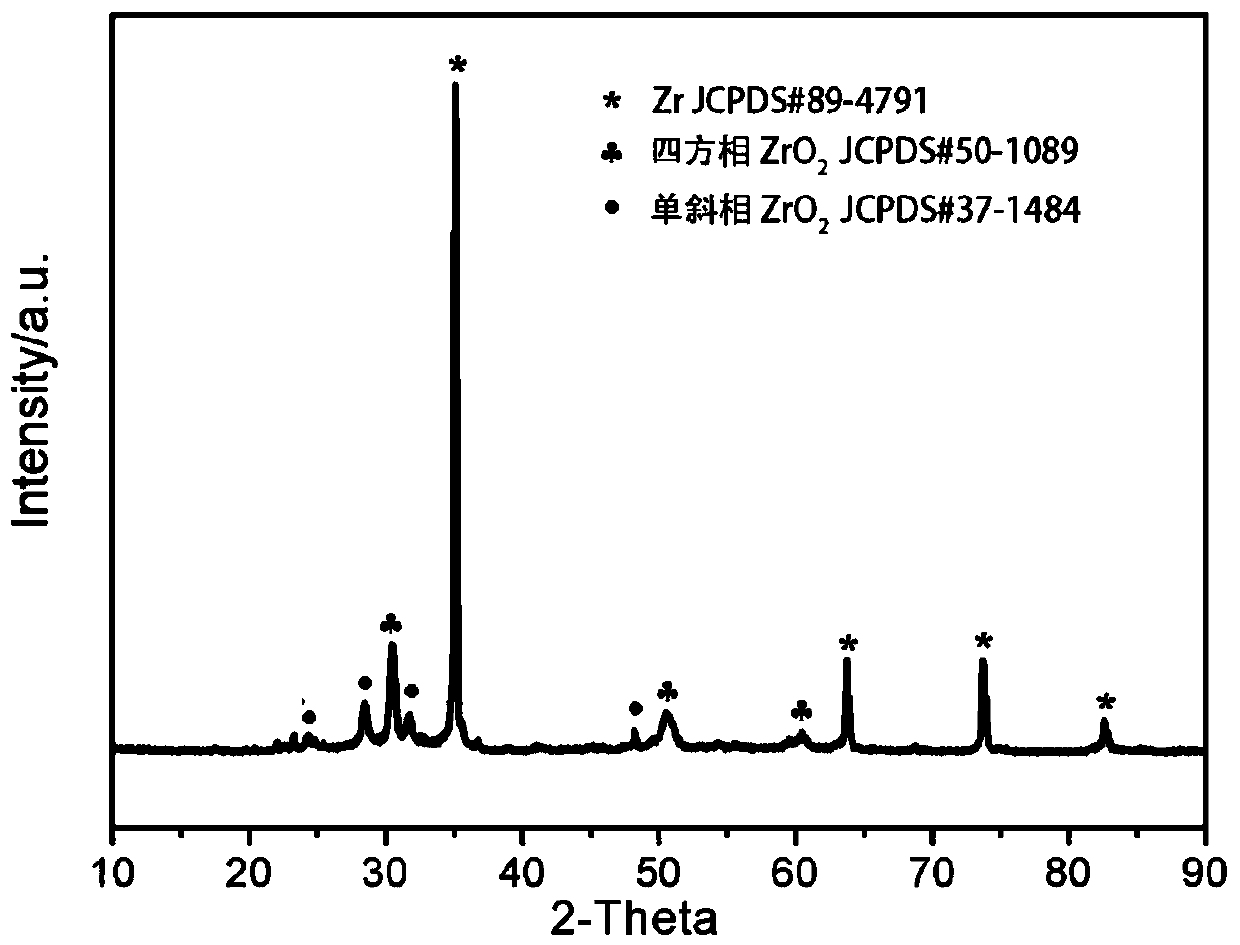

[0053] (5) Heat-treat the dried zirconia nanotube films at 500°C and 800°C respectively in an argon atmosphere for 2 hours, then cool...

Embodiment 3

[0056] (1) The anodized zirconia nanotube films prepared in steps (1)-(4) in Example 2 were heat-treated and kept for 2 hours in an argon atmosphere at 500°C, 600°C, and 800°C respectively, and then Cool down to room temperature with the furnace, and the preparation is completed, and a black zirconia nanotube film with a narrow band gap is obtained.

[0057] (2) Characterized by ultraviolet diffuse reflectance absorption spectrum, the maximum absorption peak of the black zirconia nanotube film annealed at 500°C is around 384nm, the absorption edge is around 568nm, and the optical band gap is 2.35eV, as Figure 4 As shown; after annealing at 600°C, the maximum absorption peak of the black zirconia nanotube film is around 325nm, the absorption edge is around 525nm, and the optical band gap is 2.9eV; after annealing at 800°C, the maximum absorption peak of the black zirconia nanotube film is around 436nm, It has absorption in the whole visible light range, and the optical band ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com