Single-motor inverter assembly

An inverter and single-motor technology, which is applied in the field of single-motor inverter assembly, can solve problems such as difficulty in meeting vehicle requirements and regulatory requirements, low power density, and poor safety, and achieve compact structure and high power density , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

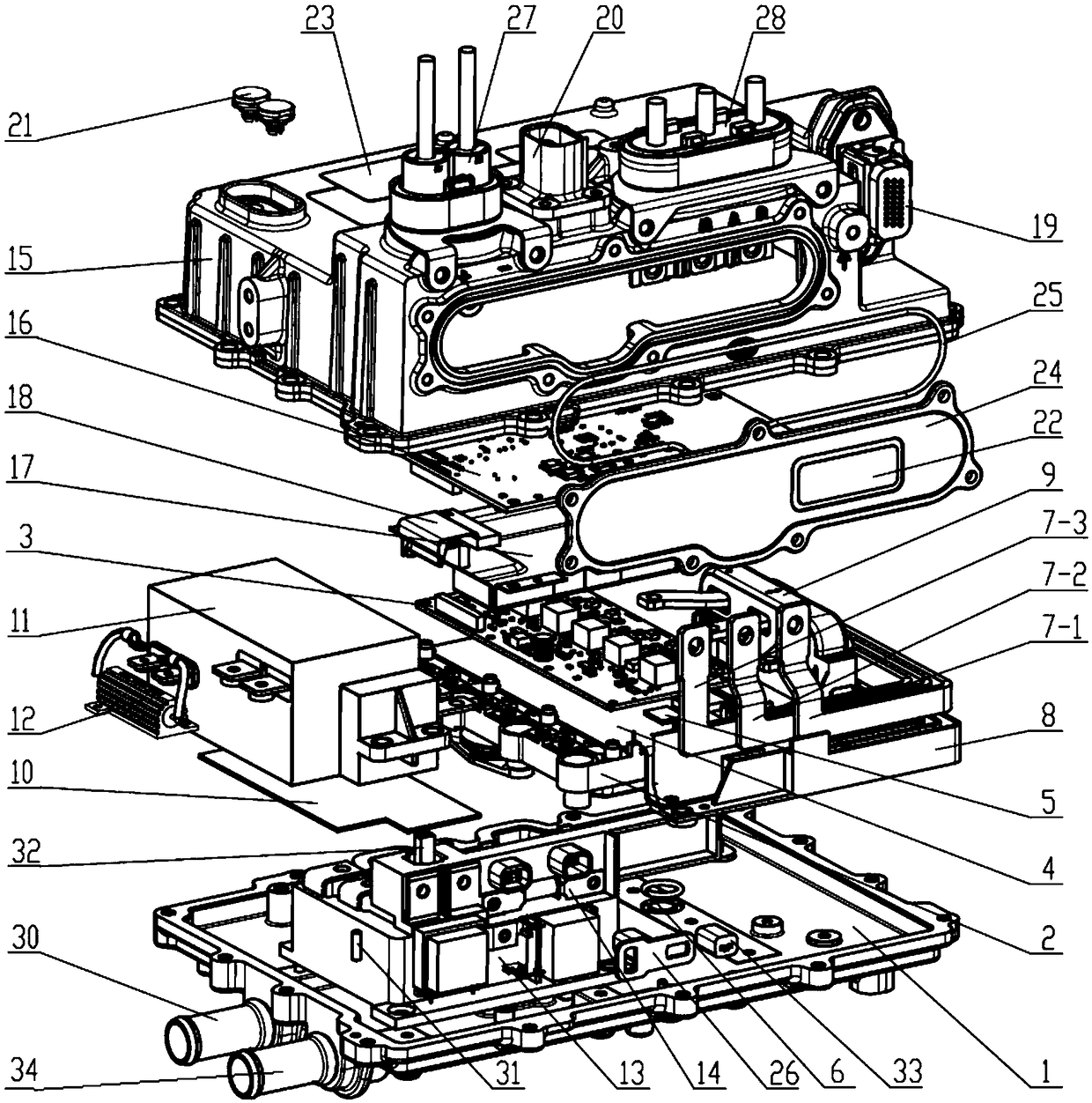

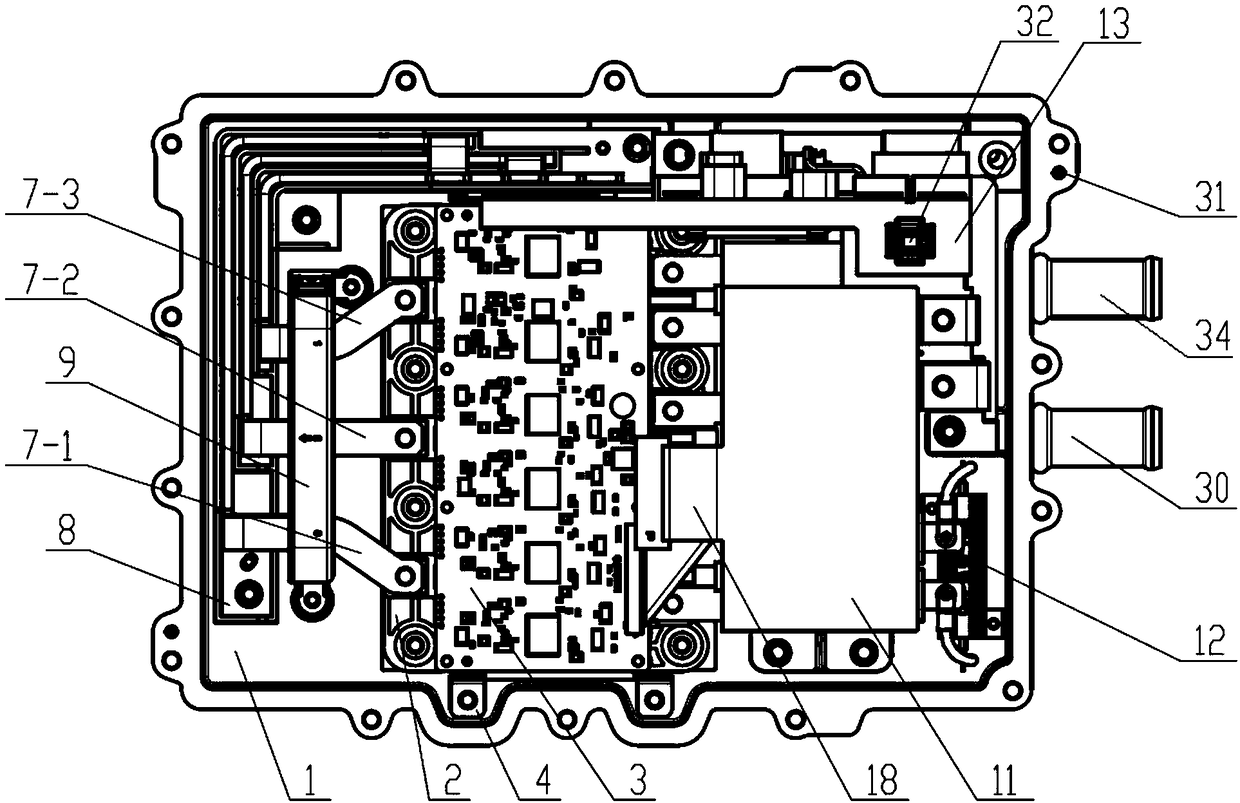

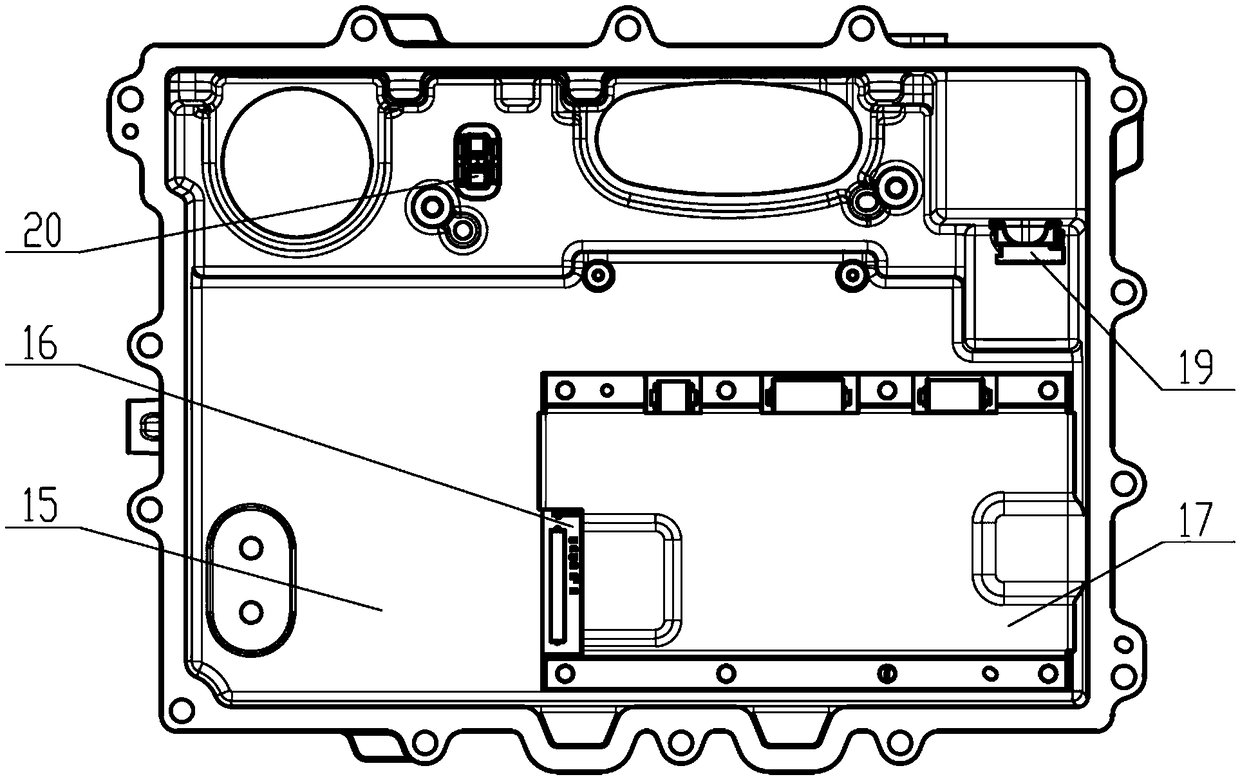

[0033] This embodiment provides a single-motor inverter assembly, which includes a main box 1, an IGBT module 2, a drive board 3, a drive board heat dissipation bracket 4, a drive board heat dissipation gasket 5, an O-ring 6, a three-phase Busbar 7 (including U-phase busbar 7-1, V-phase busbar 7-2, W-phase busbar 7-3), three-phase busbar fixing bracket 8, current sensor 9, DC bus capacitor cooling gasket 10, DC bus capacitor 11, discharge resistor 12, DC bus terminal block assembly 13, upper box body 15, control panel 16, shielding cover 17, flat cable 18, low-voltage signal connector 19, high-voltage air conditioner connector 20, pressure balance element 21. Product label 22, warning label 23, inverter end cover 24, inverter end cover sealing ring 25, end cover interlock connector 26, high voltage DC connector 27 and high voltage AC connector 28.

[0034] The main box body 1 is formed by die-casting, wherein a water inlet channel and an outlet channel are formed, the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com