System and method for synthesizing hexazinone by continuous pipeline reactions

A pipeline reaction and pipeline reactor technology, which is applied in the system field of synthesizing hexazinone, can solve the problems of difficult control of reaction speed, lower synthesis efficiency, and fast reaction speed, and achieve continuous production, stable product quality, and high production efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

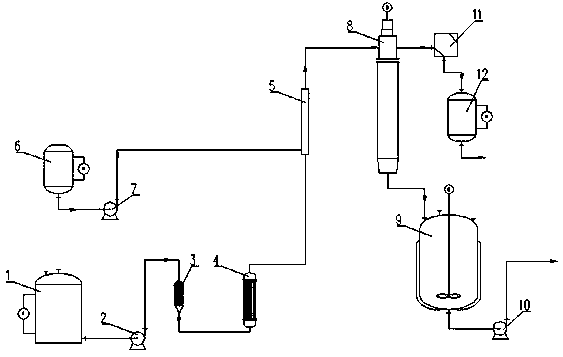

[0077] First, the toluene solution containing cyclic ester that is 18% by mass fraction is added in the first solution tank 1; secondly, the catalyst is added in advance in the second solution tank 6: the methanol solution containing sodium methylate that is 28% by mass fraction Again, the toluene solution containing cyclic ester is passed through the filter 3 and pumped in the tube preheater 4 through the flow meter with the first transfer pump 2; then, the tube preheater is passed through the thermometer and the steam regulating valve 4 Carry out steam heating to make the temperature reach 65°C and the pressure 0.3Mpa. At the same time, the methanol solution containing sodium methoxide passes through the second transfer pump 7, and the pressure is 0.3Mpa, so that the toluene solution containing cyclic ester and the toluene solution containing sodium methoxide The methanol solution simultaneously enters the pipeline reactor 5 to carry out the cyclization reaction, and the cycl...

Embodiment 2

[0080] First, the toluene solution containing cyclic ester that is 19% by mass fraction is added in the first solution tank 1; secondly, the catalyst is added in advance in the second solution tank 6: the methanol solution containing sodium methylate that is 29% by mass fraction Again, the toluene solution containing cyclic ester is passed through the filter 3 and pumped in the tube preheater 4 through the flow meter with the first transfer pump 2; then, the tube preheater is passed through the thermometer and the steam regulating valve 4 Carry out steam heating to make the temperature reach 69°C and the pressure 0.4MPa. At the same time, the methanol solution containing sodium methoxide passes through the second transfer pump 7, and the pressure is 0.4MPa, so that the toluene solution containing cyclic ester and the toluene solution containing sodium methoxide The methanol solution simultaneously enters the pipeline reactor 5 to carry out the cyclization reaction, and the cycl...

Embodiment 3

[0083] First, the toluene solution containing cyclic ester that is 20% by mass fraction is added in the first solution tank 1; secondly, the catalyst is added in advance in the second solution tank 6: the methanol solution containing sodium methylate that is 30% by mass fraction Again, the toluene solution containing cyclic ester is passed through the filter 3 and pumped in the tube preheater 4 through the flow meter with the first transfer pump 2; then, the tube preheater is passed through the thermometer and the steam regulating valve 4 Carry out steam heating to make the temperature reach 71°C and the pressure 0.5MPa. At the same time, the methanol solution containing sodium methoxide passes through the second transfer pump 7, and the pressure is 0.5MPa, so that the toluene solution containing cyclic ester and the toluene solution containing sodium methoxide The methanol solution simultaneously enters the pipeline reactor 5 to carry out the cyclization reaction, and the cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com