Aromatic polyimine thermosetting resin and preparation method thereof

A thermosetting and polyimine technology, applied in the field of thermosetting resins, can solve the problems of difficult recycling of composite materials, inability to melt and plasticize, waste of resources, etc., and achieve controllable and adjustable reaction process, good hydrophobicity, and mild preparation reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

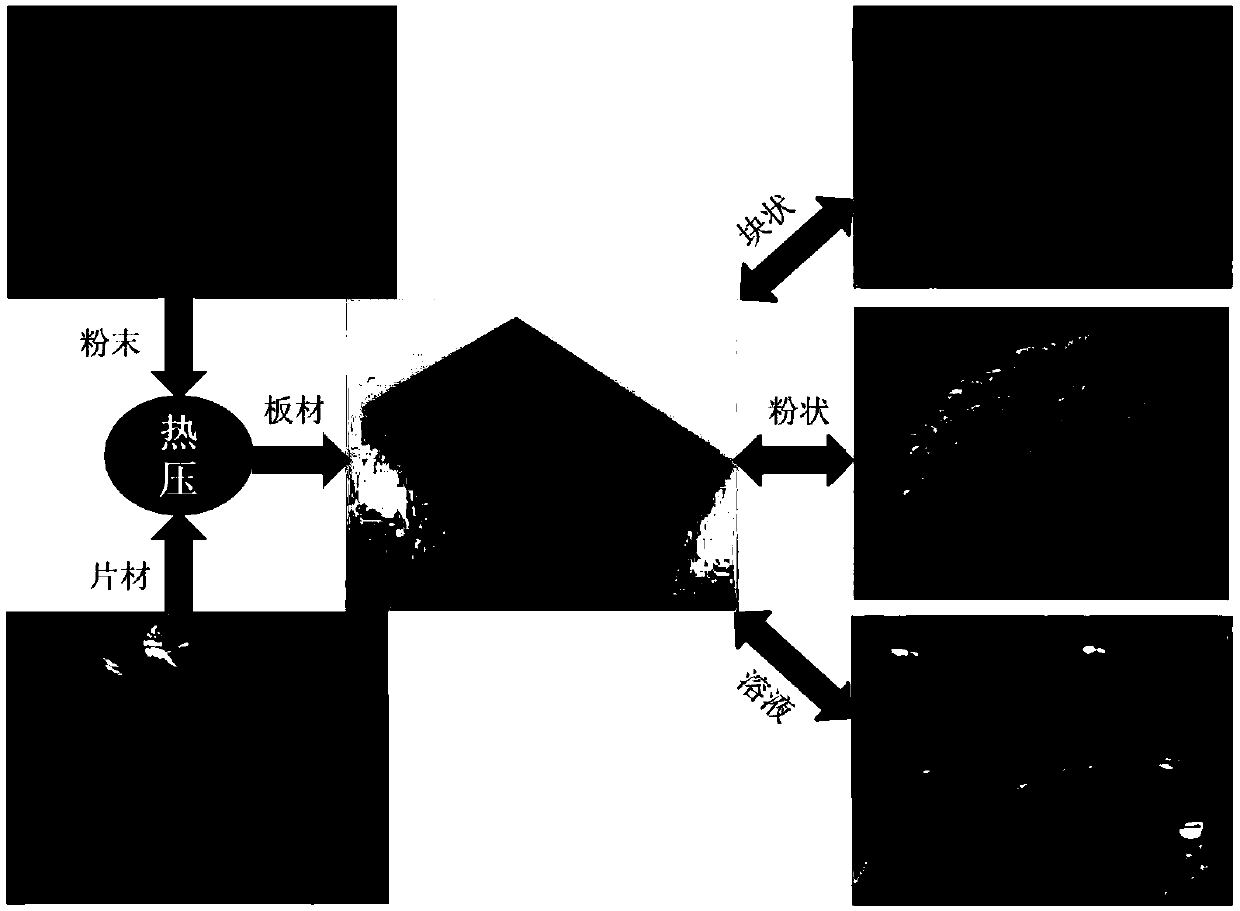

Method used

Image

Examples

Embodiment 1

[0033] Add 80mmol tris[(4-formylphenoxy)-methyl]ethane and 120mmol 4,4'-bis(4-aminophenoxy)diphenyl sulfone into 250ml N-methylpyrrolidone solvent, in Stir and react at 60°C for 1 hour, then coat the reaction pre-polymerization solution on a horizontal glass plate, and dry at 120°C for 1 hour to obtain a sheet-like material. Put multiple sheets of material into a mold for hot pressing under the conditions of 180°C and 5MPa to obtain polyimide resin sheets with different thicknesses. The tensile strength, Young's modulus and elongation at break of the resin are 118Mpa, 3.5Gpa and 7% respectively, and the bending strength and modulus reach 138MPa and 3.1Gpa respectively. The glass transition temperature is 155°C, the 5wt% thermal decomposition temperature is 430°C, and the contact angle with water is 103°. Add 30g of resin to 200ml of N-methylpyrrolidone dissolved in 17.5g of 4,4'-bis(4-aminophenoxy)diphenyl sulfone, place it at 60°C for 6h, the resin is completely dissolved, t...

Embodiment 2

[0035] Add 80 mmol tris[(4-formylphenoxy)-methyl]ethane and 120 mmol 2,2'-bis[4-(4-aminophenoxyphenyl)]propane to 300 ml dimethyl sulfoxide In a solvent, stir and react at 90°C for 0.1h, then coat the reaction prepolymer on a horizontal glass plate, and dry at 120°C for 1h to obtain a sheet-like material. Put multiple sheets of material into a mold for hot pressing under the conditions of 220°C and 15MPa to obtain polyimide resin sheets with different thicknesses. The tensile strength, Young's modulus and elongation at break of the resin are 95Mpa, 3.3Gpa and 11% respectively, and the bending strength and modulus reach 124MPa and 2.9Gpa respectively. The glass transition temperature is 221°C, the thermal decomposition temperature of 5wt% is 440°C, the contact angle with water is 95°, and the water absorption rate is 0.2wt%. Add 30g of resin to 200ml of dimethyl sulfoxide dissolved in 21g of 2,2'-bis[4-(4-aminophenoxyphenyl)]propane, place it at 40°C for 36h, the resin is comp...

Embodiment 3

[0037] Add 80mmol tris[(4-formylphenoxy)-methyl]ethane and 120mmol 2,2'-bis[4-(4-aminophenoxyphenyl)]propane into 600ml ethanol solvent, Stir and react at 50°C for 1.5h, a yellow precipitate precipitated at the bottom, filter, and dry at 120°C for 2h to obtain a yellow powder. The powder is evenly added into the mold for hot pressing under the conditions of 220°C and 10MPa to obtain polyimide resin plates with different thicknesses. The tensile strength, Young's modulus and elongation at break of the resin are 93Mpa, 3.2Gpa and 10.7% respectively, and the bending strength and modulus reach 122MPa and 2.8Gpa respectively. The glass transition temperature is 213°C, the thermal decomposition temperature of 5wt% is 436°C, the contact angle with water is 95°, and the water absorption rate is 0.2wt%. Add 30g of resin to 200ml of ethanol dissolved in 21g of 2,2'-bis[4-(4-aminophenoxyphenyl)]propane, place it at 50°C for 12h, the resin is completely dissolved, then add 14.8g of tris[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com