Submicron-scale lumpy calcium titanate based upconversion luminescent material and preparation method thereof

A luminescent material, submicron technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of high preparation temperature, uneven size, irregular shape, etc., and achieve stable physicochemical properties, uniform size, and regular shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing a submicron block calcium titanate-based up-conversion luminescent material, comprising the following steps:

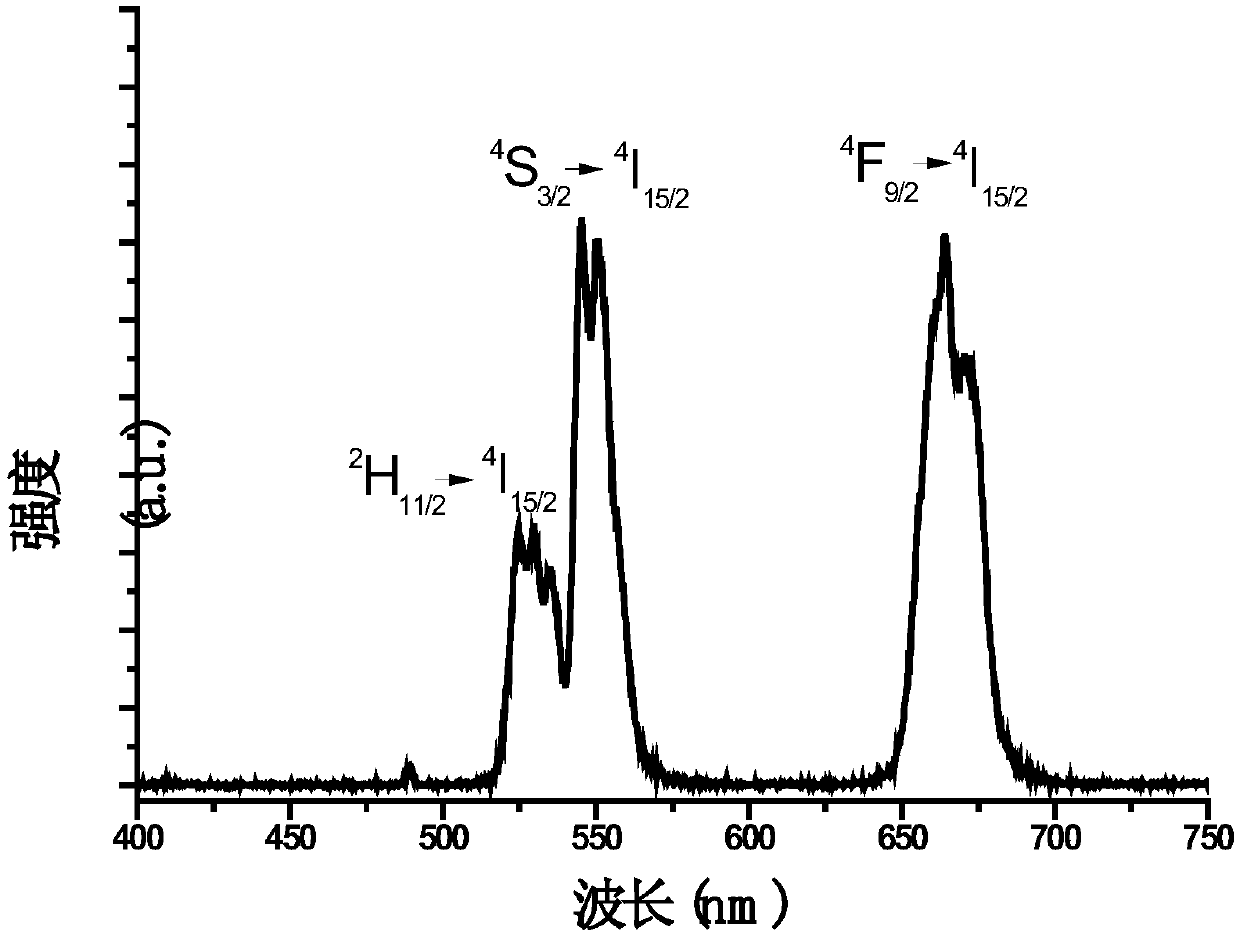

[0039] The chemical expression of the submicron bulk calcium titanate-based up-conversion luminescent material is Ca (1-x-y) TiO 3 :M 3+ x , Yb 3+ y ; where x and y are mole fractions of elements, and their value ranges are: 0.0001≤x≤0.10, 0.0001≤y≤0.20, and M is one of the rare earth elements Ho and Er;

[0040] Step 1, measure Ca(NO 3 ) 2 , Yb(NO 3 ) 3 , and Er(NO 3 ) 3 or Ho(NO 3 ) 3 , after mixing these three nitrates, add 16.27mL-17.22mL polyethylene glycol PEG-200, n(Ca 2+ +Yb 3+ +Er 3+ or Ho 3+ )=1mmol, prepared to obtain alcohol mixed solution;

[0041] Step 2. Add 0.33mL tetrabutyl titanate dropwise into the alcohol mixed solution prepared in step 1, and stir for 30min;

[0042] Step 3, adjust the mixed solution prepared in step 2 with an aqueous sodium hydroxide solution, the concentratio...

Embodiment 1

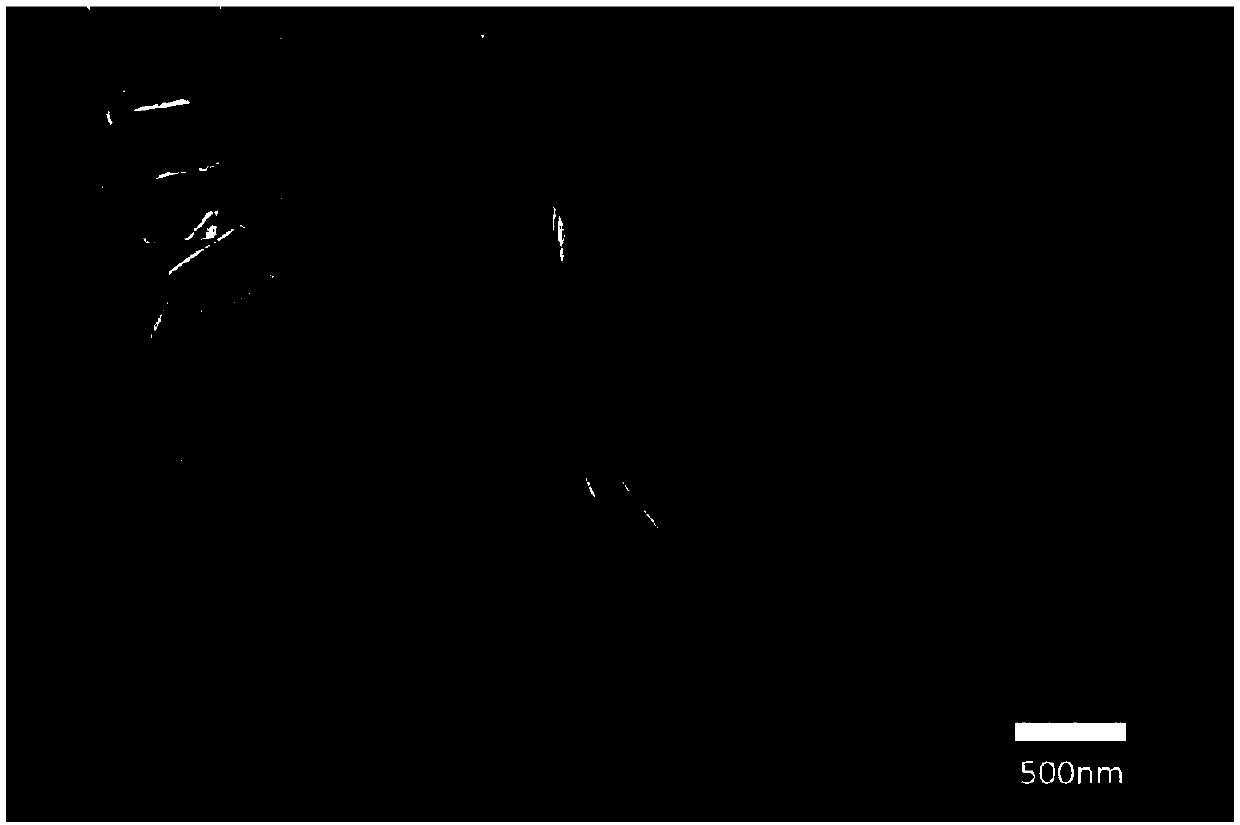

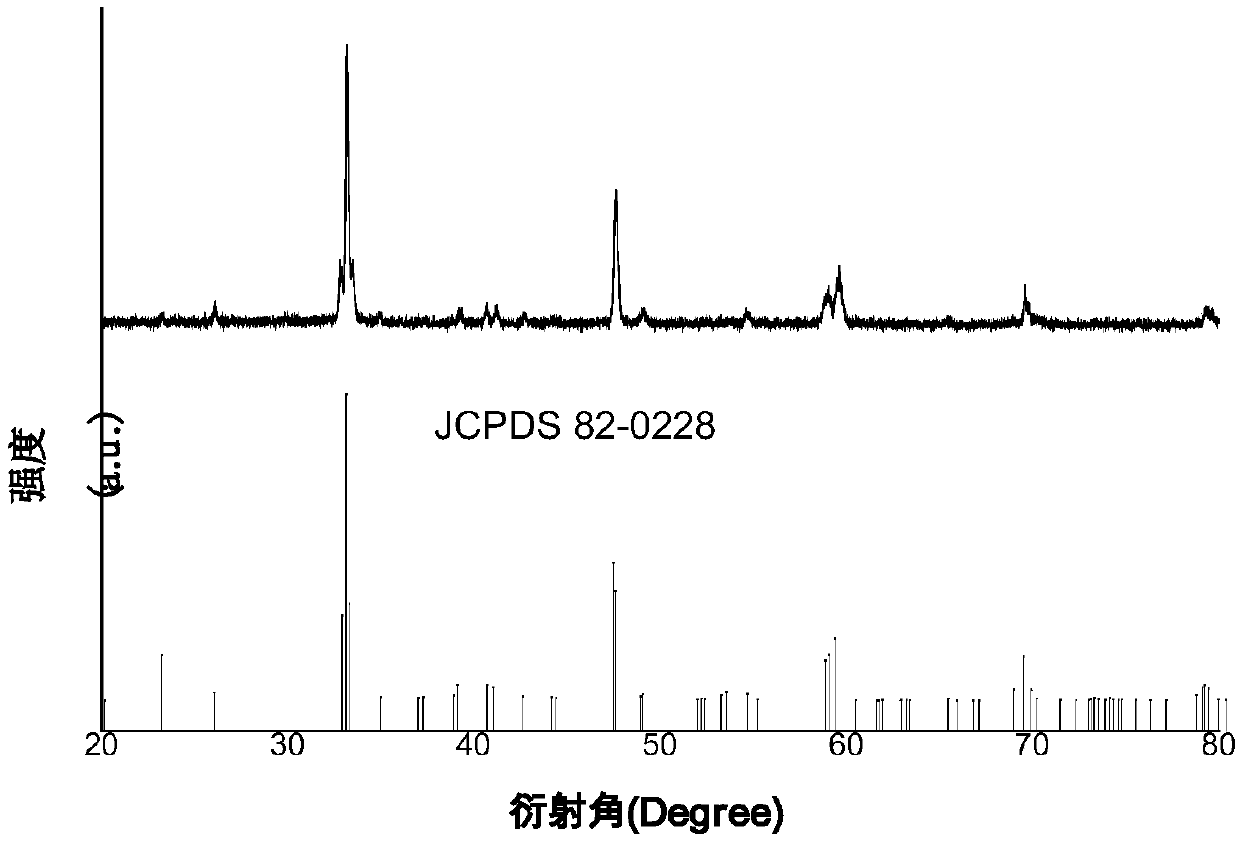

[0053] By expression Ca (1-x-y) TiO 3 :M 3+ x , Yb 3+ y , y=0.03, x=0.01, the stoichiometric ratio of each substance in the 50mL small beaker is respectively measured 240 μ L Ca(NO 3 ) 2 , 150μL Yb(NO 3 ) 3 , 50μL Er(NO 3 ) 3 , then add about 17.03mL polyethylene glycol PEG-200; add 0.33mL tetrabutyl titanate dropwise to the above mixture while stirring, stir for 30min, then add sodium hydroxide dropwise to the above mixture while stirring Aqueous solution 2.2mL, stirred for 30min, the obtained suspension was put into a hydrothermal reaction kettle at 180°C for 15 hours, cooled naturally, the precipitate was taken out by centrifugation, first with acetone, then with dilute acetic acid, and finally with absolute ethanol Wash by centrifugation 3 times. Put it in an oven and dry at 80°C for 15 hours to obtain the precipitate of the reactant precursor; put the precipitate of the reactant precursor into a corundum crucible and cover it, and place it in a high-temperature...

Embodiment 2

[0059] By expression Ca (1-x-y) TiO 3 :M 3+ x , Yb 3+ y , y=0.15, x=0.01, the stoichiometric ratio of each substance in the 50mL small beaker is respectively measured 210 μ L Ca(NO 3 ) 2 , 750 μL Yb (NO 3 ) 3 , 50μL Er(NO 3 ) 3 , then add about 16.46mL of polyethylene glycol PEG-200; add 0.33mL of tetrabutyl titanate dropwise to the above mixed solution while stirring, stir for 30min, then add sodium hydroxide dropwise to the above mixed solution while stirring Aqueous solution 2.2mL, stirred for 30min, the obtained suspension was put into a hydrothermal reaction kettle at 180°C for 15 hours, cooled naturally, the precipitate was taken out by centrifugation, first with acetone, then with dilute acetic acid, and finally with absolute ethanol Wash by centrifugation 3 times. Put it in an oven and dry at 80°C for 15 hours to obtain the precipitate of the reactant precursor; put the precipitate of the reactant precursor into a corundum crucible and cover it, and place it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com