A method of brewing Chardonnay dry white

A dry white and dry powder technology, applied in the field of wine brewing technology, can solve the problems of insufficient mellowness and aroma concentration, abnormal fluctuation of fermentation temperature, unsatisfactory fermentation temperature, etc., to enhance the complexity of aroma, increase the concentration of aroma, Scientific and reasonable effect of equipment application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

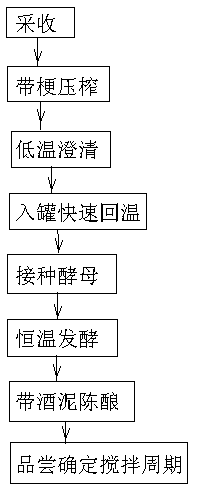

[0030] A method for brewing high-quality Chardonnay dry white, comprising the following steps:

[0031] S1. Determine the grape raw material plots, detect sugar, acid and PH, determine the optimal sugar-acid ratio and harvest. The average acidity of Chardonnay is 6-7g / L, and the average sugar content is 210-215g / L;

[0032] Controlling the acidity of Chardonnay is the support of the aroma. If the acidity is too low, it needs to be adjusted. The control of sugar content is to ensure that there is enough sugar in the later stage to achieve a reasonable alcohol content for fermentation.

[0033] S2. Grapes with stalks are put into the airbag press, adding pectinase 0.02g / L before feeding, adding potassium metabisulfite 0.5g / L, VC 0.02g / L during feeding, and controlling the total sulfur dioxide concentration to 50-60mg / L ;

[0034] Pectinase can promote the dissolution of pigments and healthy ingredients in grape skins, crack plant cell walls, increase the nutritional content of...

Embodiment 2

[0044] A method for brewing high-quality Chardonnay dry white, comprising the following specific process steps:

[0045] S1. Harvesting Chardonnay grapes, the average acidity is controlled at 6-7g / L, and the average sugar content is controlled at 215-220g / L;

[0046] S2. Grapes with stalks are put into the airbag press, adding pectinase 0.04g / L before feeding, adding potassium metabisulfite 1.5g / L, VC 0.06g / L during feeding, and controlling the total sulfur dioxide concentration to 60-70mg / L ;

[0047] S3. The squeezed grape juice is first put into the clarification tank and clarified at a low temperature of 6-8°C, and then sent to a stainless steel barrel when the turbidity of the grape juice is <100NTU;

[0048] Before entering the tank and barrel, fill the clarification tank and stainless steel barrel with CO 2 , carry out oxygen barrier to prevent oxidation of grape juice;

[0049] S4. Quickly return the grape juice in the stainless steel barrel to the temperature by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com