Composite material I-shaped stiffened wall plate curing molding device and molding method

A composite material, curing molding technology, applied in the field of composite material reinforced wall panel curing molding device, can solve the problems of uneven thickness, deviation of long truss axis, poor overall molding quality, etc., to improve internal quality, control Axial degree, the effect of improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A solidification and molding device for composite material I-shaped reinforced wall panels

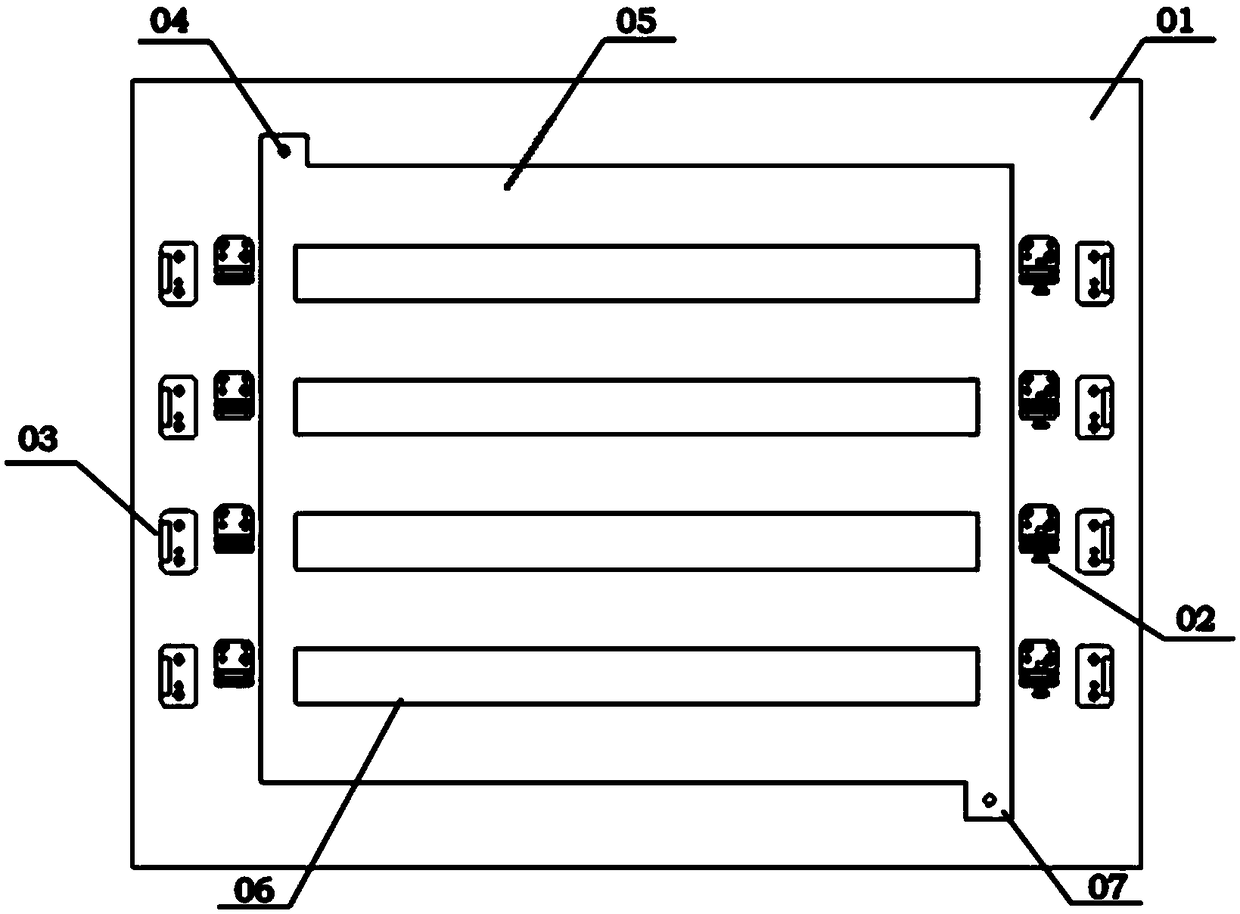

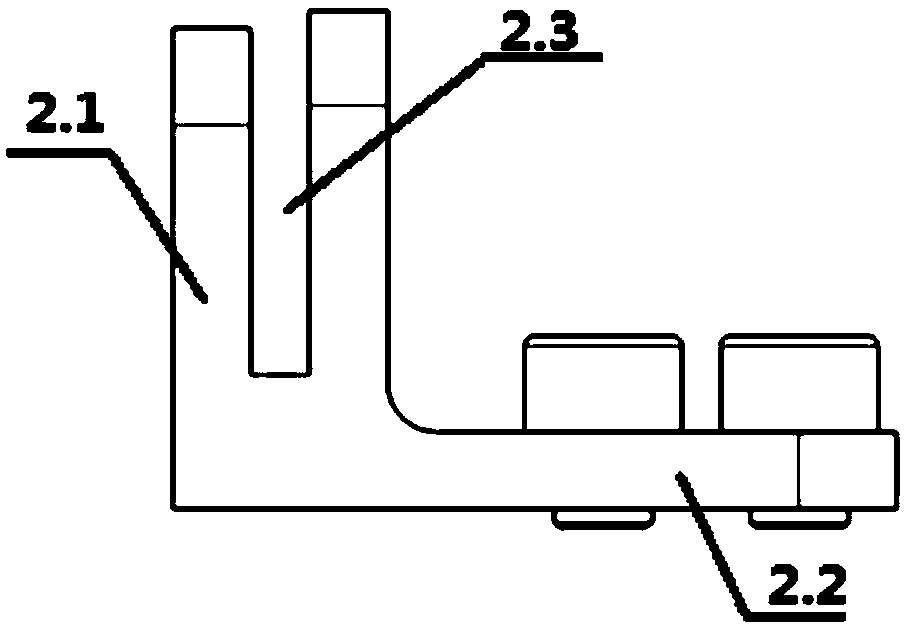

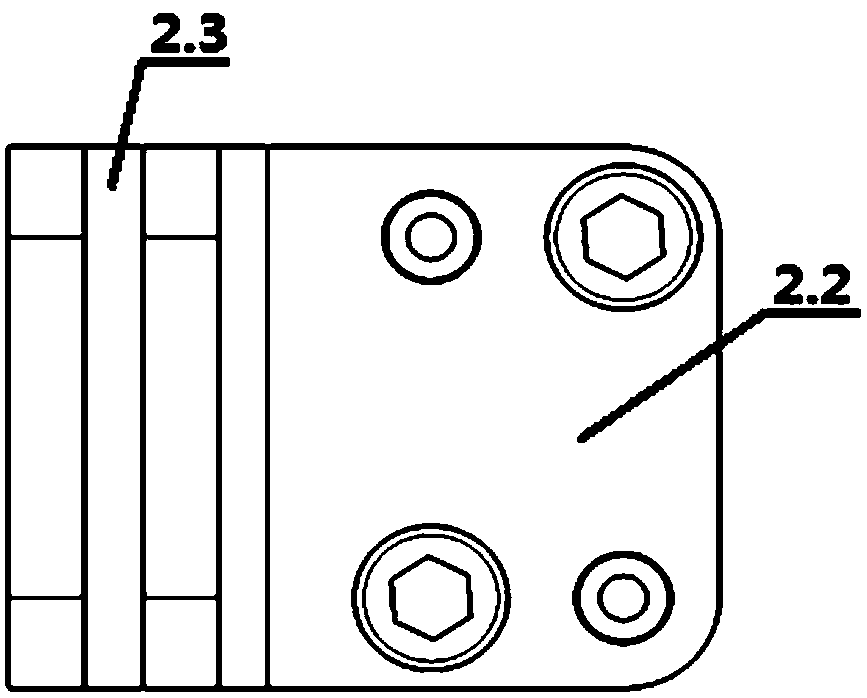

[0036] Such as figure 1 The forming device shown is a frame structure, including a skin forming panel 1, a skin forming process cover plate 5, a long stringer positioning seat 2, a long stringer upper edge strip cover plate 10, an upper edge strip cover plate support seat 3, positioning Mandrel 8 and pressure transmission mandrel 9.

[0037] Among them: the skin forming panel 1 is used for paving the carbon fiber composite skin; the panel material of the skin forming panel 1 is a composite panel or invar steel material to reduce the thermal expansion during the part forming process. The cover plate 5 of the skin forming process is a composite material structure, and the cover plate 5 of the skin forming process is provided with several long stringer limiting grooves 6 parallel to each other; the size of the long stringer limiting grooves 6 is the same as The size of...

Embodiment 2

[0041] Embodiment 2: A kind of solidification forming method of composite I-shaped reinforced wallboard

[0042] This molding method adopts the molding device described in Embodiment 1, and the main molding process flow chart is as follows Figure 5 Shown, with the following steps:

[0043] (1) First, lay a carbon fiber composite material skin on the skin forming panel 1, and reserve 10-25mm margin around the skin;

[0044] (2) Apply release agent on the side of the skin forming process cover plate 5 close to the skin and around the girder limit groove 6, and use the positioning lugs reserved on the skin forming process cover plate 5 to pass the positioning The pin is positioned with the positioning hole 4 on the skin forming panel 1, and placed on the paved skin surface to obtain a skin prefabricated body;

[0045] (3) After combining the left and right webs, upper and lower edge strips and one-way strip carbon strips of the laid long stringers, remove them from the long st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com