Preparation method of controllable nitrogen-doped carbon nanotubes

A technology of nitrogen-doped carbon and nanotubes, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of high cost, complex process, difficult large-scale and extensive production, etc., to improve cycle life, process The effect of simple, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

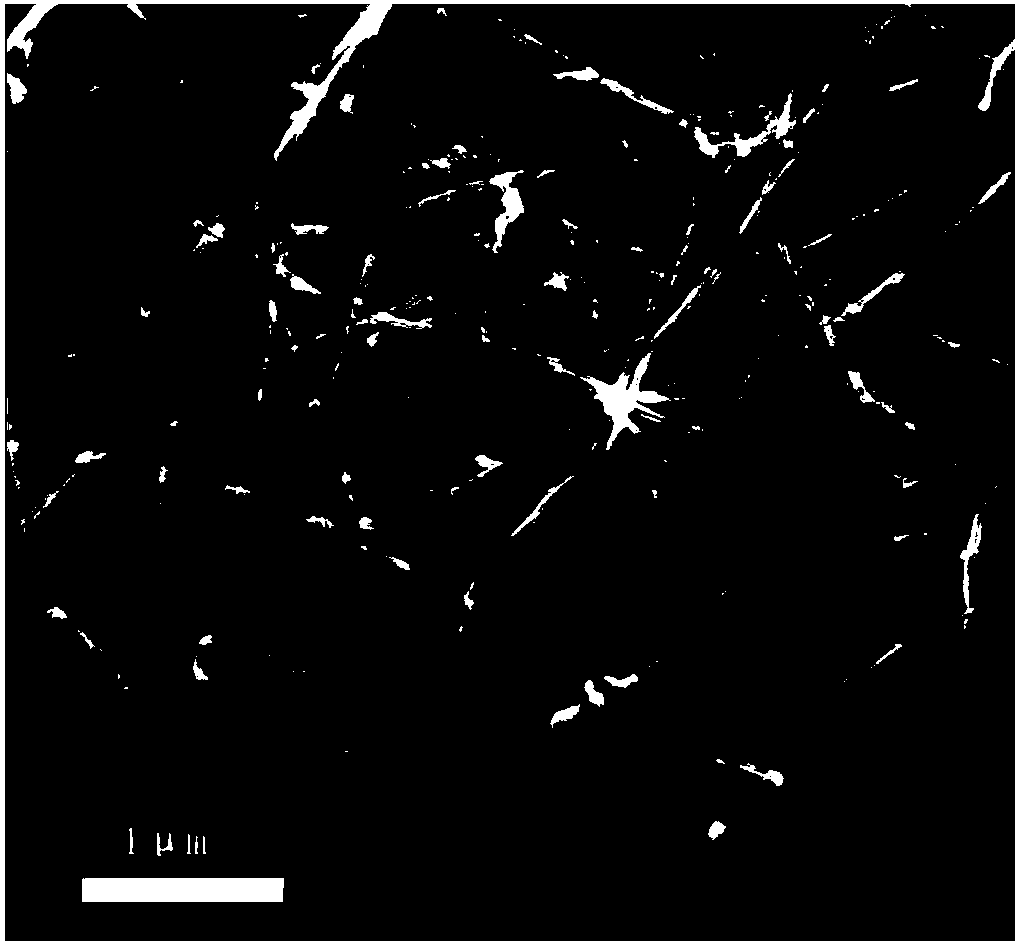

[0022] Dissolve 0.17mol urea in 50mL deionized water, then add 0.005mol citric acid and 0.008mol nickel acetate, add 150mL absolute ethanol after complete dissolution, and stir well. The mixed solution was vigorously stirred at 75° C. for 3 h until a sol-like form appeared. The sol samples were dried in an oven at 100 °C for 12 h. After drying, place the gel sample in a drying cabinet for 4-6 hours to completely dehumidify and dry it to obtain a precursor. The precursor was placed in a tube furnace, and the temperature was raised to 350 °C for 2 h at a heating rate of 5 °C / min, and then the temperature was raised to 750 °C for 5 h at the same heating rate. Natural cooling after heat preservation is completed to obtain nitrogen and metal carbon nanotubes, and then simple corrosion to obtain pure nitrogen-containing carbon nanotubes. SEM characterization as figure 1 As shown, the TEM characterization is as follows figure 2 As shown, the diameter of the nanotube is about 60-...

Embodiment 2

[0024] Dissolve 0.32 mol of urea in 50 mL of deionized water, then add 0.004 mol of citric acid and 0.004 mol of nickel acetate, and stir evenly. The mixed solution was vigorously stirred at 60° C. for 3 h until a sol appeared. The sol samples were dried in an oven at 120 °C for 12 h. After drying, place the sample in a drying cabinet for 4-6 hours to completely cool and dry to obtain a precursor. The precursor was placed in a tube furnace, and the temperature was raised to 350 °C for 4 h at a heating rate of 5 °C / min, and then the temperature was raised to 750 °C for 10 h at the same heating rate. Natural cooling after heat preservation is completed to obtain nitrogen and metal carbon nanotubes, and then simple corrosion to obtain pure nitrogen-containing carbon nanotubes.

Embodiment 3

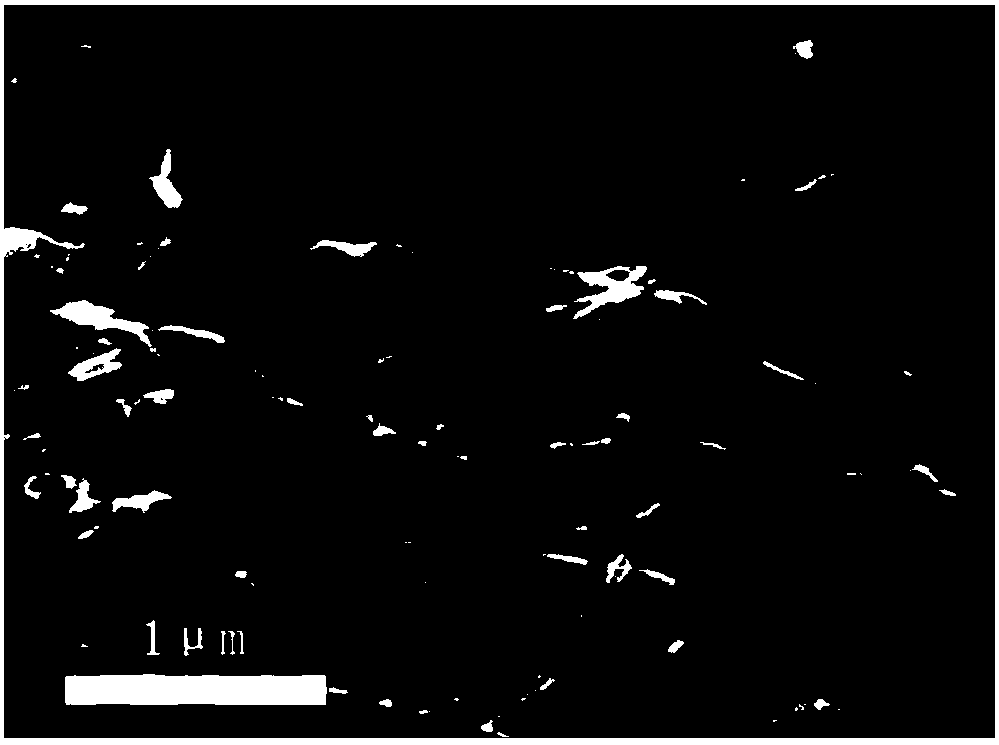

[0026] Dissolve 0.12 mol of thiourea in 50 mL of deionized water, then add 0.006 mol of glucose and 0.012 mol of cobalt acetate, add 150 mL of absolute ethanol after complete dissolution, and stir well. The mixed solution was vigorously stirred at 75 °C for 3 h until a sol appeared. The sol samples were dried in an oven at 100°C for 10 h. After drying, place the sample in a drying cabinet for 4-6 hours to completely cool and dry to obtain a precursor. The precursor was placed in a tube furnace, and the temperature was raised to 650 °C for 4 h at a heating rate of 2 °C / min, and then the temperature was raised to 1000 °C for 10 h at the same heating rate. Natural cooling after the heat preservation is over, carbon nanotubes containing nitrogen and metal sulfides can be obtained, and then pure nitrogen-containing carbon nanotubes can be obtained through simple corrosion. SEM characterization as image 3 As shown, the diameter of the nanotube is about 150-200nm, and the length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com