Method for preparing isosorbitol by dehydration of sorbitol

A technology for isosorbide and sorbitol, applied in the field of chemical preparation, can solve the problems of harsh reaction conditions, low yield of isosorbide, etc., and achieve the effects of mild reaction conditions, easy separation, high practicability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

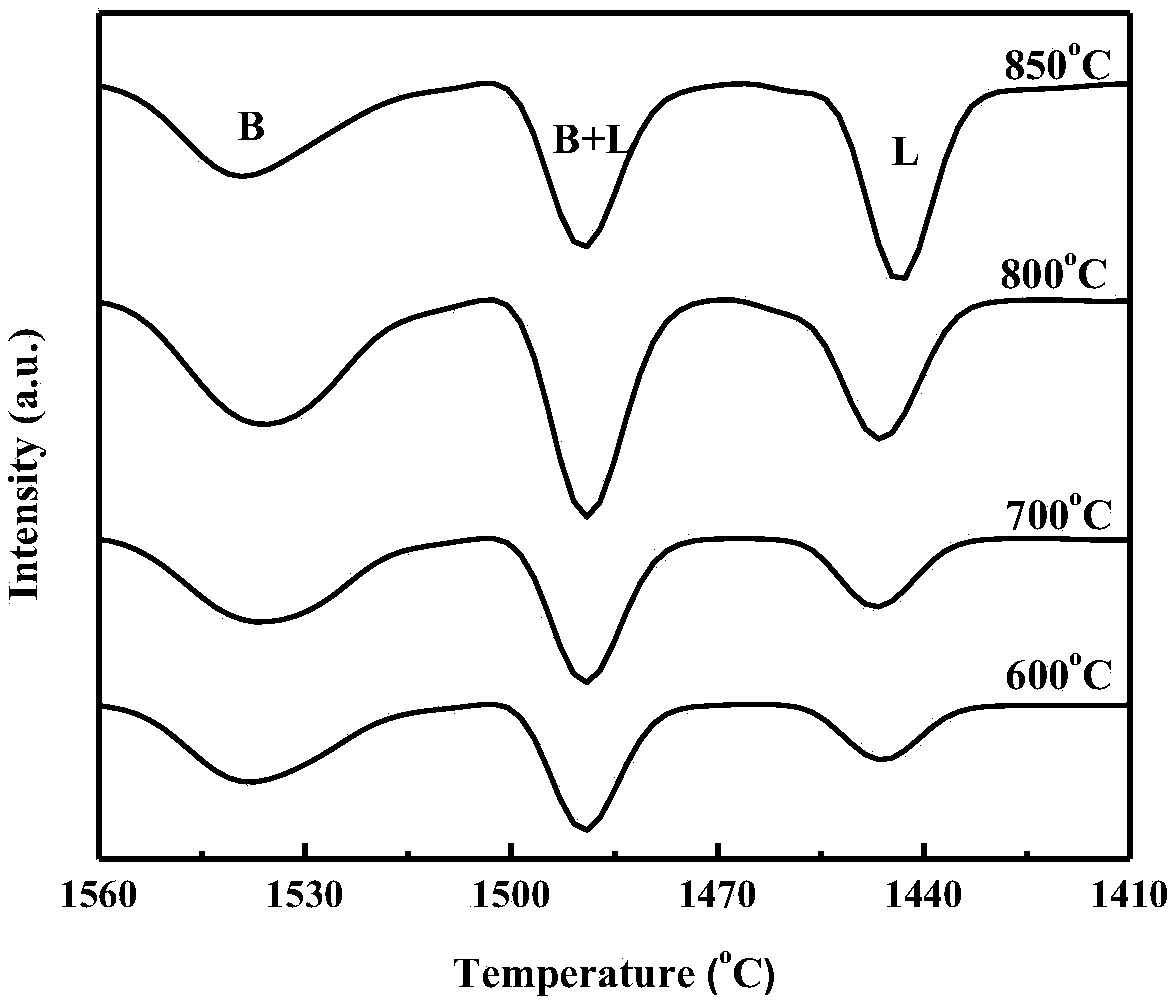

[0020] Taking the preparation of H-15%W / Zr-800 solid acid as an example, the catalyst preparation process is described in detail.

[0021] Zr(OH) 4 Precursor preparation

[0022] 50g ZrOCl 2 ·8H 2 O was dissolved in 450ml water, stirred for 30min, 35mL NH 3 ·H 2 Add ZrOCl dropwise at room temperature with O (25-28%) 2 ·8H 2 O aqueous solution, stirring, while adding dropwise, use a pH meter to measure the pH. When the pH meter reads 9.0, stop adding ammonia water dropwise, stir at room temperature for 1 hour, reflux at 100°C for 10 hours, and filter the obtained white precipitate with deionized water. Wash to free of Cl - , and with AgNO 3 (0.1mol / l) solution detection, drying at 95°C for 10h to obtain Zr(OH) 4 .

[0023] Preparation of WO by Equal Volume Impregnation 3 / ZrO 2

[0024] Dissolve 3g ammonium metatungstate in 24mL water, stir evenly, add 20g Zr(OH) 4 , immerse at room temperature for 24 hours, remove water in a water bath at 80°C, dry at 110°C for 1...

Embodiment 2

[0028] Taking the preparation of Cop-15%W / Zr-800 as an example, the catalyst preparation process is described in detail.

[0029] 30g ZrOCl 2 ·8H 2 Dissolve O in 270ml of water, stir evenly, dissolve 2.2g of ammonium metatungstate in 28mL of water, add ZrOCl dropwise to the ammonium metatungstate solution 2 ·8H 2 O aqueous solution, stirring vigorously at room temperature for 0.5 h, adding NH 3 ·H 2 O (25-28%), while adding dropwise, use a pH meter to measure the pH. When the pH meter reads 9.0, stop the dropwise addition, stir at room temperature for 2 hours, age at 100°C for 24 hours, filter, and wash the obtained white precipitate with deionized water to no Cl -, and with AgNO 3 (0.1mol / l) solution detection, drying at 110°C for 10h, and roasting the dried precipitate in a tube furnace at 800°C for 3h, the calcined catalyst is marked as Cop-15%W / Zr-800, where n represents WO 3 weight percent content.

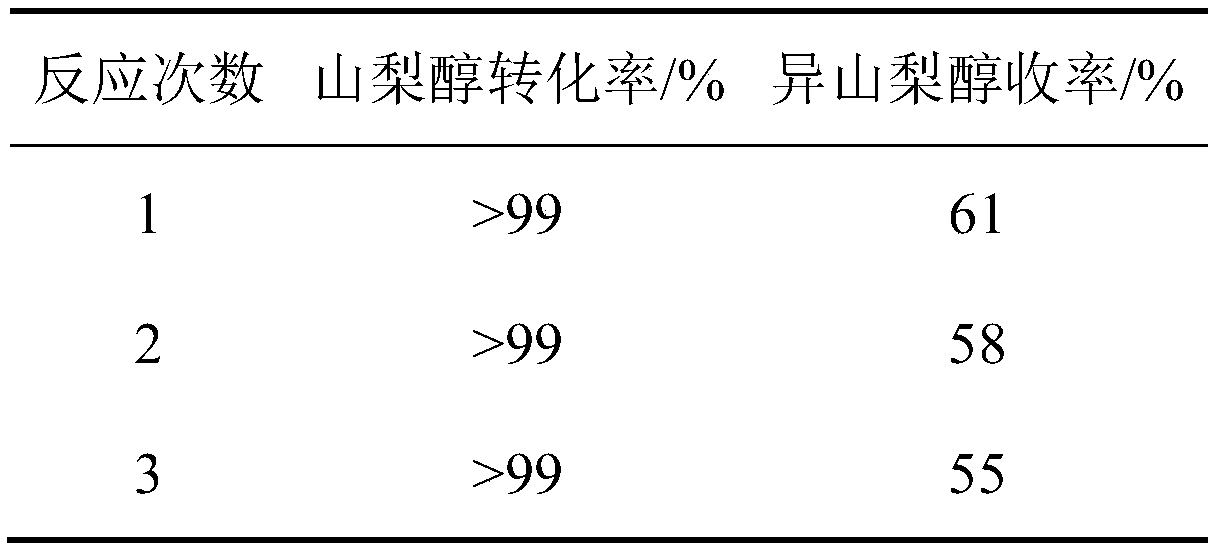

[0030] Cop-15%W / Zr-800 catalyzes the dehydration process of sorb...

Embodiment 3

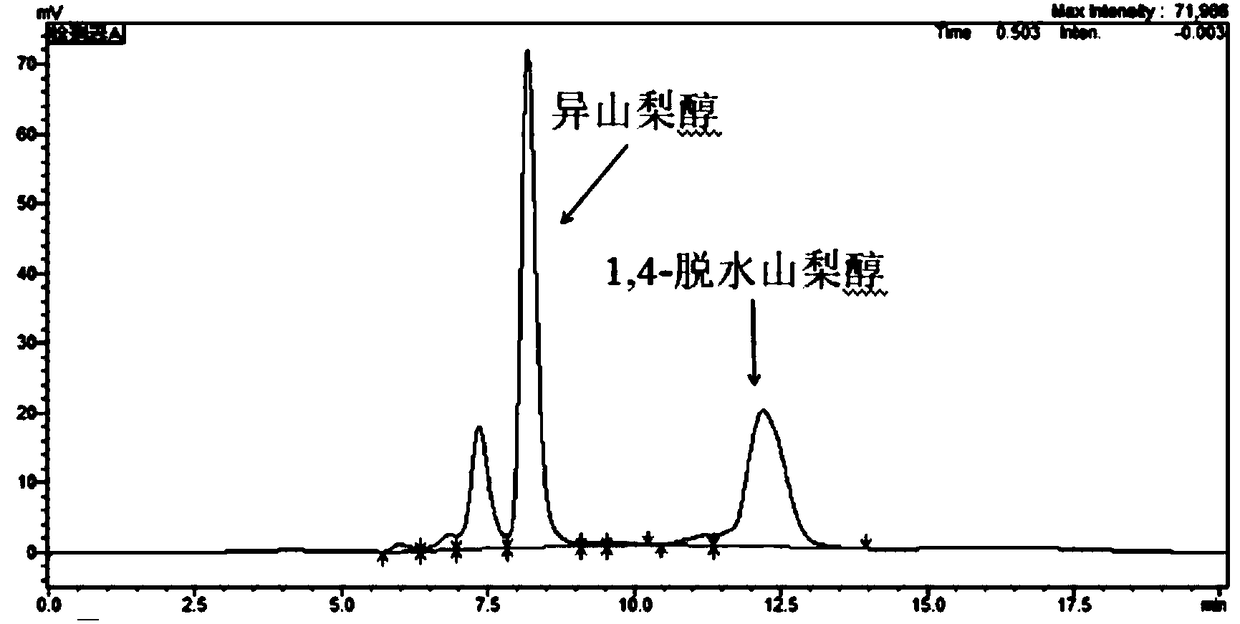

[0032] The process of H-20%W / Zr-800 catalyzing the dehydration of sorbitol to prepare isosorbide is as follows: first add 20g sorbitol to the flask, heat it to 210°C, add 1.2g H-20%W / Zr after the sorbitol melts -800, turn on the vacuum pump to decompress the reaction device to 3000Pa, the reaction time is 2h, and the stirring speed is 600r / min. After the reaction, cool to room temperature, add 100ml of water to extract the product, and use high performance liquid chromatography to detect the sample. The conversion of sorbitol was >99%, and the yield of isosorbide was 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com