Durable superhydrophobic coating

A technology of coatings and nano-additives, applied in coatings, fiber treatment, textiles and papermaking, etc., can solve problems such as cumbersome preparation process, high-cost coating coating chemistry and environmental tolerance, coating safety and comfort , to achieve high durability, excellent long-term tolerance, simple application and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0180] Example 1: Materials and methods

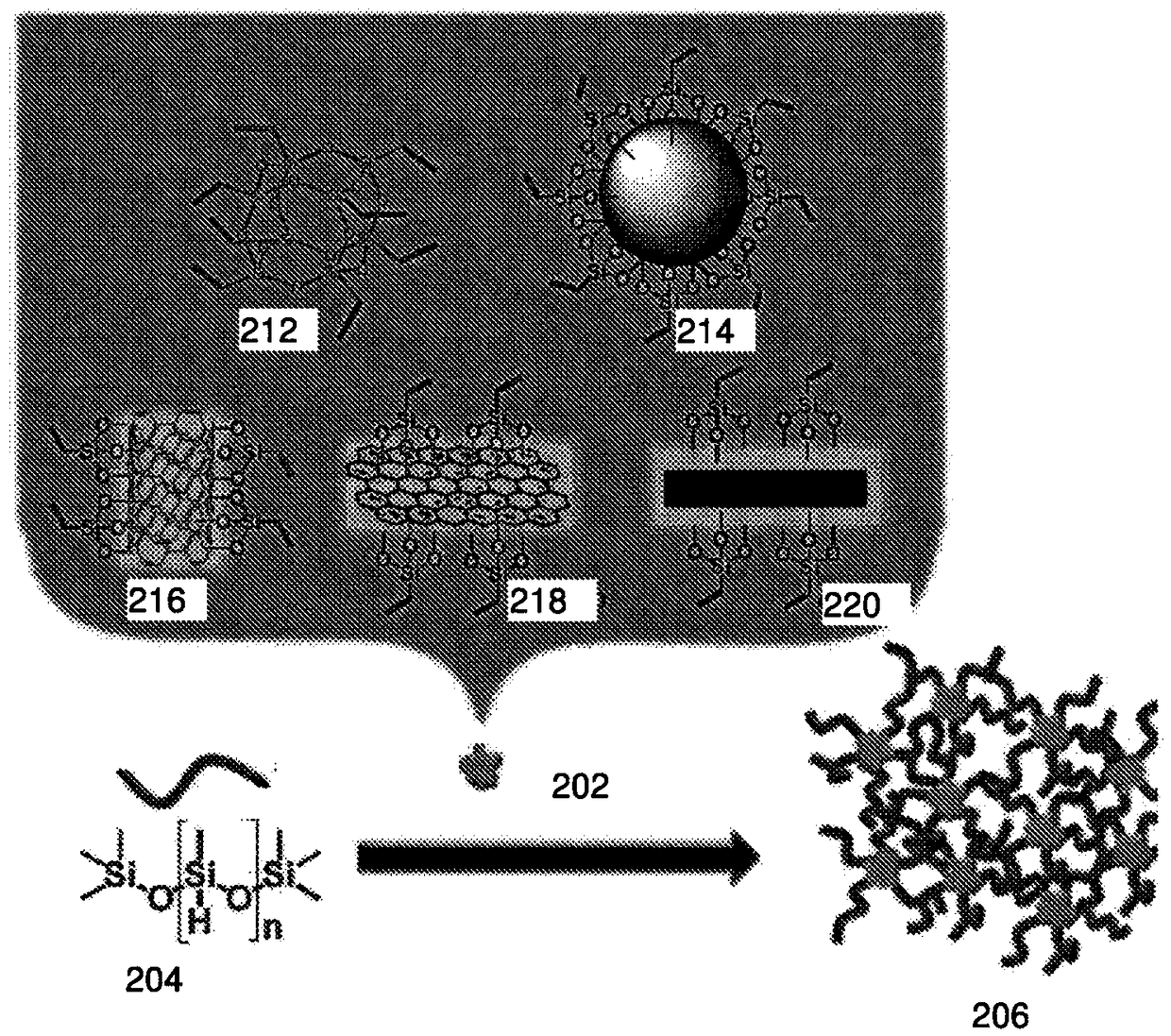

[0181] Material

[0182] Poly(methylhydrogensiloxane) (average Mn 1,700-3,200, PMHS), poly(dimethylsiloxane-co-methylhydrogensiloxane) (trimethylsilyl-terminated, (PDMS / PMHS), (Mn is about 13,000, methylhydrogensiloxane accounts for 3-4mol%) is purchased from Sigma-Aldrich. The clay used is alkyl quaternary ammonium salt bentonite "CLOISITE 30B". Other chemicals are purchased from Sigma -Aldrich and used as is.Water was purified using Millipore Milli-Q water system.

[0183] method

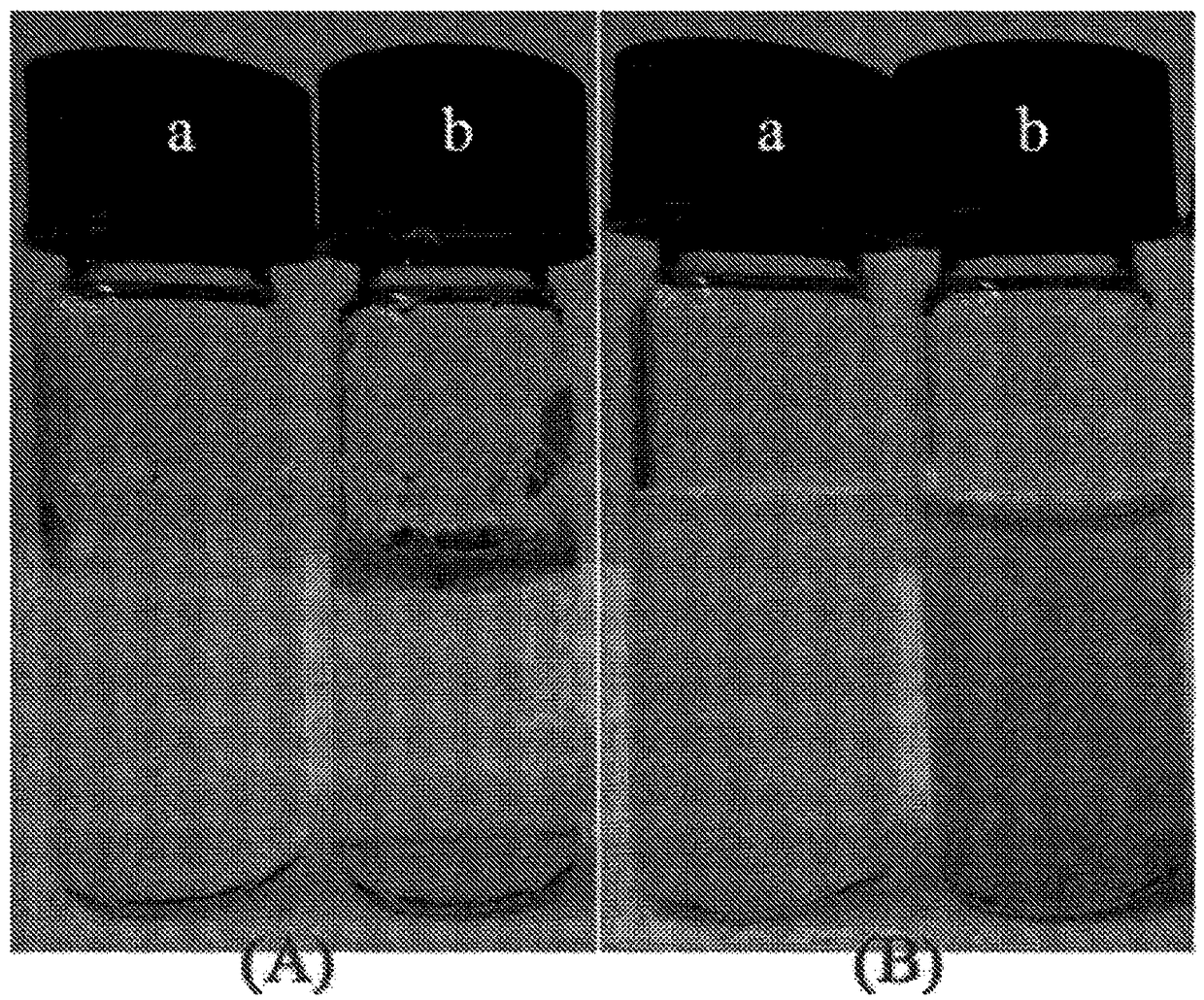

[0184] Scanning electron microscope (SEM) images were taken using a JEOL JSM 6700F operating at an accelerating voltage of 5.0 kV. Contact angle (CA) measurements were performed on a ramé-hart contact angle goniometer using a droplet volume of 5 μL. Fourier transform infrared (FTIR) spectroscopy was performed on a Bruker VERTEX 70 instrument in ATR mode at 4 cm -1 The resolution record was accumulated 32 times.

Embodiment 2

[0185] Embodiment 2: synthesis

Embodiment 2A

[0186] Example 2A: Preparation of Vinylsilane Functionalized Silica Nanoparticles (SiNPs)

[0187] Briefly, tetraethoxysilane (TEOS, 10 mL) and ammonium hydroxide (10 mL) were dissolved in a solution of ethanol / water (428 mL / 60 mL, v / v) and gently stirred at 30°C for 2 hours. The white product was washed 4 times with ethanol and distilled water, respectively. The resulting surfactant-free SiNPs were dried overnight in a vacuum oven at 40 °C to remove the remaining solvent. Then, SiNPs (1.00 g) were refluxed in 80.00 mL of anhydrous toluene with 0.25 mL (1.00 mmol) of trimethoxy(vinyl)silane for 20 hours to produce vinylsilane-functionalized SiNPs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com