Carbon fiber interlayer composite acoustic panel and preparation method and application thereof

A technology of carbon fiber and sound insulation panels, which is applied in the field of carbon fiber sandwich composite sound insulation panels and its preparation, can solve the problems of limited designability and achieve obvious vibration isolation effects, good fatigue resistance, and flexible design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of carbon fiber interlayer composite sound insulation board

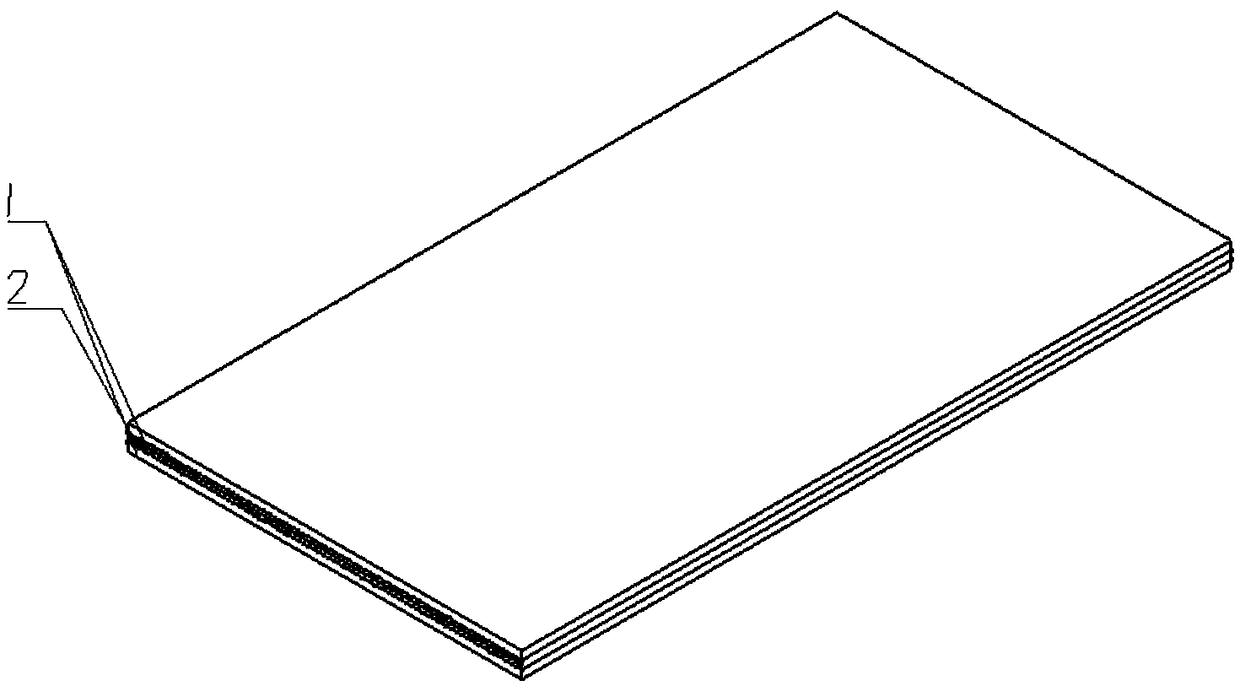

[0030] A carbon fiber sandwich composite sound-insulating board, comprising: a carbon fiber upper surface skin layer, a carbon fiber lower surface skin layer, and at least one layer of sound-insulation and vibration-insulation composite interlayer in between. See figure 1 .

[0031] Wherein, the thickness ratio of the carbon fiber upper surface skin layer, sound insulation and vibration isolation composite interlayer, and carbon fiber lower surface skin layer is 1:1.5:1, specifically 0.8cm, 1.2cm, and 0.8cm. Among them, the carbon fiber upper and lower surface skin layers are obtained by laying carbon fiber prepregs into the mold, heating and pressing and curing; wherein, the carbon fiber prepregs are laid at an angle of 0° / 90° / ±45° / 0°.

[0032] The sound-insulating and vibration-insulating composite interlayer 2 is composed of polymethacrylimide or polystyrene foam boards foamed by sand...

Embodiment 2

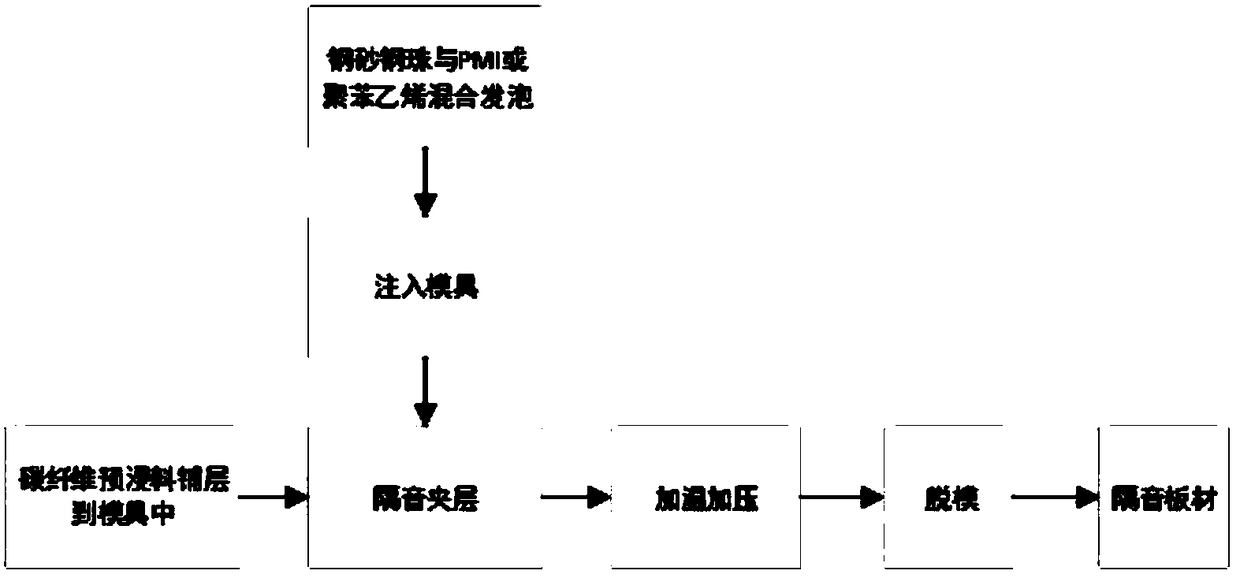

[0034] Embodiment 2 A kind of preparation method of carbon fiber interlayer composite sound insulation board

[0035] A method for preparing a carbon fiber sandwich composite sound insulation board, comprising:

[0036] Step 1: Adding 10% to 15 mass fraction of steel balls or steel grit to the polymethacrylimide or polystyrene foam material for mixing and foaming to obtain a sound-insulating composite layer;

[0037] Step 2: Clean the mold and apply a release agent in the mold;

[0038] Step 3: Calculate the number of plies and the thickness of the sound-insulating composite layer based on the thickness of the sound-insulating board. The thickness of the sound-insulating composite layer is about 1 / 3 of the thickness of the sound-insulating board, and lay the carbon fiber prepreg on the forming mold of the sound-absorbing board In, pre-embedded in the sound insulation interlayer;

[0039] Step 4: After closing the mold, place it in an autoclave for heating and pressurization,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com