Preparation method of impervious and permeable sand

A technology of breathable sand and preparation steps, which is applied in the field of building material preparation, which can solve the problems of strong water permeability of sand, ineffective absorption of plants, poor air permeability, etc., and achieve the effects of enhanced hydrophobicity, improved anti-seepage performance, and improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

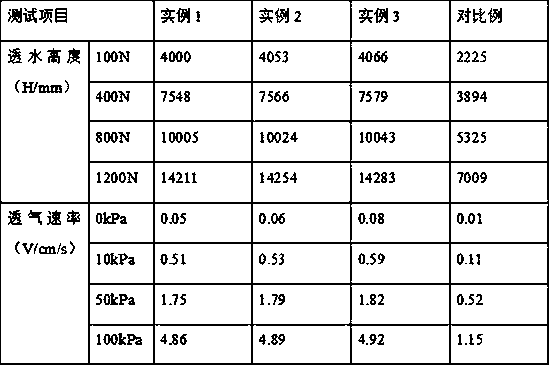

Examples

example 1

[0024] According to the mass ratio of 1:1, mix the sodium chloride solution with a mass fraction of 30% and ammonium bicarbonate and put it into a beaker, then put the beaker into a water bath, heat up to 40°C, stir for 30 minutes, and filter and separate to obtain Filter residue: put the above filter residue into a crucible, then move the crucible into a heating box, heat up to 80°C, and keep it warm for 1 hour. After the reaction, mix the reaction product and water in the crucible in an equal mass ratio to obtain a self-made modification solution; Weigh the aeolian sand and put it into the ball mill, and add zirconia ball milling beads into the ball mill tank according to the mass ratio of the ball to material at 20:1, ball mill and pulverize for 40 minutes, and pass through a 100-mesh sieve to collect the sifted powder, and sieve the sifted powder and The above-mentioned self-made modified liquid is mixed according to a mass ratio of 1:8, then put into an ultrasonic oscillat...

example 2

[0026]According to the mass ratio of 1:1, mix the sodium chloride solution with a mass fraction of 30% and ammonium bicarbonate and put it into a beaker, then put the beaker into a water bath, heat up to 45°C, stir for 35 minutes, and filter and separate to obtain Filter residue: put the above filter residue into a crucible, then move the crucible into a heating box, heat up to 90°C, and keep it warm for 1 hour. After the reaction, mix the reaction product and water in the crucible in an equal mass ratio to obtain a self-made modification solution; Weigh the aeolian sand and put it into the ball mill, and add zirconia ball milling beads into the ball milling pot according to the ball mass ratio of 20:1, ball milling for 45min, and pass through a 100 mesh sieve to collect the sieved powder, and sieve the sifted powder and The above-mentioned self-made modified liquid is mixed according to a mass ratio of 1:8, then put into an ultrasonic oscillator, oscillated and impregnated at ...

example 3

[0028] According to the mass ratio of 1:1, mix the sodium chloride solution with a mass fraction of 30% and ammonium bicarbonate and put it into a beaker, then put the beaker into a water bath, heat up to 50°C, stir for 40 minutes, and separate by filtration to obtain Filter residue: put the above filter residue into a crucible, then move the crucible into a heating box, heat up to 100°C, and keep warm for 2 hours. After the reaction, mix the reaction product and water in the crucible in an equal mass ratio to obtain a self-made modification solution; Weigh the aeolian sand and put it into the ball mill, and add zirconia ball milling beads into the ball milling pot according to the mass ratio of the ball to material at 20:1, ball milling and pulverizing for 50 minutes, and pass through a 100 mesh sieve to collect the sifted powder, and sieve the sifted powder and The above-mentioned self-made modified liquid is mixed according to a mass ratio of 1:8 and then put into an ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com