Transition metal doped carbon microsphere as well as preparation method and application thereof

A transition metal, transition metal salt technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve problems such as cumbersome methods, achieve uniform distribution, increased pore structure, good The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

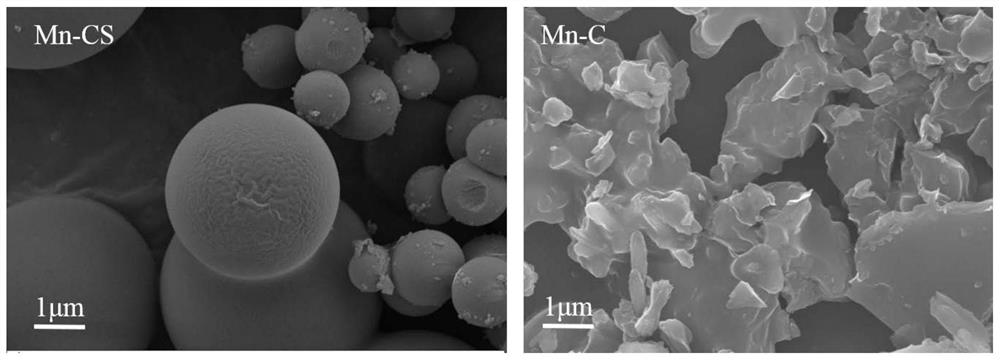

[0043] This example relates to the preparation of Mn-doped carbon spheres (Mn-CS) and the control sample Mn-doped carbon material (Mn-C), and the non-destructive activation of Mn-CS by potassium oxalate to prepare Mn-ACS.

[0044] 4 parts by mass of sucrose, 1 part by mass of KMnO 4 , 3 parts by mass of APS (ammonium persulfate) were dissolved in 40 parts by volume of water, and then the mixed solution was transferred to a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, placed in a hot air oven and heated to 180 ° C and then kept warm React for 4 hours; filter the reaction solution, wash the filter cake three times with water and ethanol, and dry it in a hot air oven at 80°C for 8 hours, and name it as Mn-CS. The Mn content therein is 0.89wt%.

[0045] A control sample Mn-C was prepared in the same manner as above without adding APS. Follow the same method as above without adding KMnO 4 A control sample CS was prepared with APS.

[0046] The SEM com...

Embodiment 2

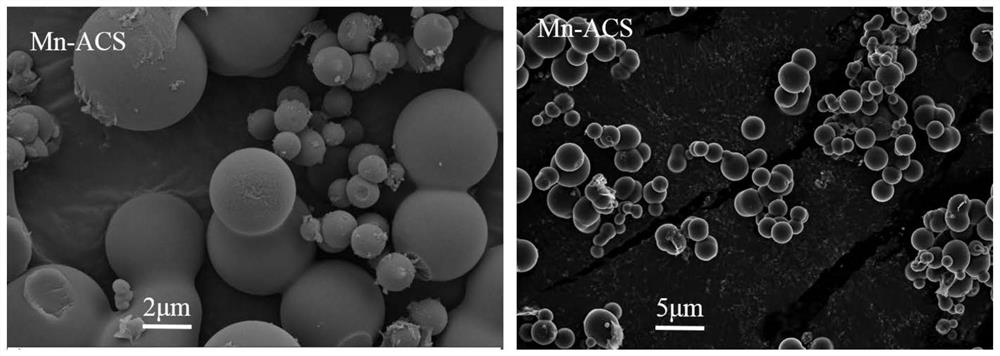

[0050] This example relates to the preparation of Mn-doped carbon spheres (Mn-CS), and the nondestructive activation of Mn-CS by potassium oxalate to prepare Mn-ACS.

[0051] 4 mass parts of sucrose, 4 mass parts of KMnO 4 1. Dissolve 5 parts by mass of APS in 40 parts by volume of water, then transfer the mixed solution into a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, place it in a hot air oven and heat it up to 180°C, then keep it warm for 4 hours; filter the reaction solution , the filter cake was washed three times with water and ethanol, and then dried in a hot air oven at 80 °C for 8 h, named Mn-CS. The Mn content therein is 2.31 wt%.

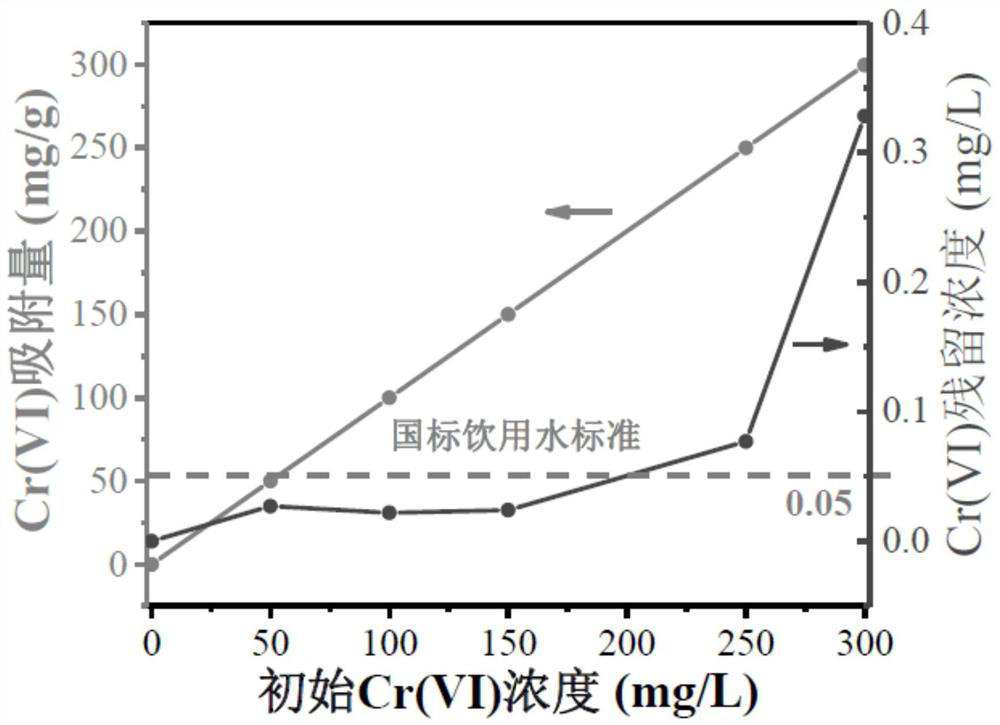

[0052] Take 1 mass part of the Mn-CS sample, mix it with 3 mass parts of potassium oxalate, transfer it into a ceramic boat, and place it in a tube furnace, pass in nitrogen to replace the air in the furnace, and then adjust the nitrogen flow rate to 30mL / min. Raise to 800°C at a heating rate of 3°C / min, ba...

Embodiment 3

[0056] This example relates to the preparation of V-doped carbon spheres (V-CS) and the control sample V-doped carbon material (V-C), and the non-destructive activation of V-CS by potassium oxalate to prepare V-ACS.

[0057] 4 parts by mass of sucrose, 1 part by mass of Na 3 VO 4 1. Dissolve 3 parts by mass of APS in 40 parts by volume of water, then transfer the mixed solution into a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, place it in a hot air oven, heat it up to 180°C, and keep it warm for 4 hours; After filtration, the filter cake was washed three times with water and ethanol respectively, and then the filter cake was dried in a hot air oven at 80°C for 8 hours, and named as V-CS. The V content therein is 2.59wt%.

[0058] Without adding APS, control samples V-C were prepared according to the same method. The SEM comparison photos of V-CS and V-C are as follows Figure 5 As shown, V-CS is smooth spherical, and V-C is fused irregular bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com