Cleaner production technology for producing sodium metabisulfite and sodium chloride through saline-alkaline mixed liquor

A sodium pyrosulfite, clean production technology, applied in the preparation of alkali metal sulfite, alkali metal sulfite/sulfite, alkali metal chloride, etc., can solve the problem of high cost of evaporation and separation of salt, and poor product quality control , high cost and other issues, to achieve obvious economic and environmental benefits, realize resource utilization, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

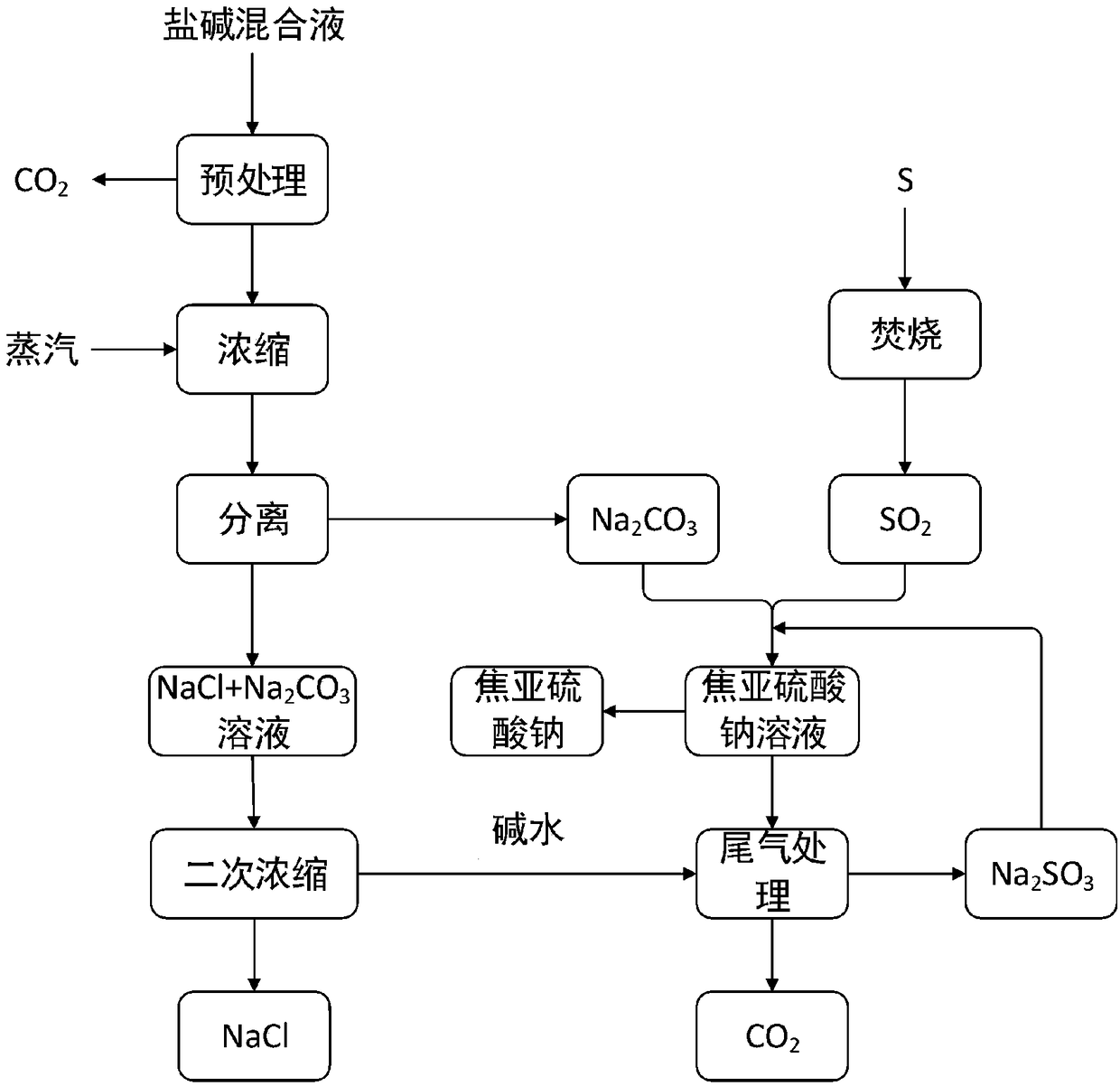

[0018] See attached figure 1 , the clean production technique that saline-alkali mixed liquor of the present invention produces sodium metabisulfite and sodium chloride, its steps are as follows:

[0019] 1) Heat 1000kg of saline-alkali mixed solution (containing 100kg of sodium carbonate, 30kg of sodium bicarbonate, and 5kg of sodium chloride) to 105°C, and dissolve the NaHCO in the solution 3 converted to Na 2 CO 3 , remove part of CO 2 , to NaHCO in solution 3 The balance is less than 5kg;

[0020] 2) CO removal 2 The final saline-alkali mixture is evaporated and concentrated by MVR (Mechanical Vapor Recompression);

[0021] 3) When the sodium chloride in which the mixed solution is concentrated is close to saturation (sodium chloride saturation solubility 35.9g), the wet product Na is separated by crystallization of the cooling solution. 2 CO 3 Solid; the remaining mother liquor is evaporated twice by MVR. When the sodium carbonate in the evaporation liquid is clos...

Embodiment 2

[0025] See attached figure 1 , the clean production technique that saline-alkali mixed liquor of the present invention produces sodium metabisulfite and sodium chloride, its steps are as follows:

[0026] 1) Heat 1000kg of saline-alkali mixed solution (which contains 80kg of sodium carbonate, 70kg of sodium bicarbonate, and 6kg of sodium chloride) to 115°C, and dissolve the NaHCO in the solution 3 converted to Na 2 CO 3 , remove part of CO 2 , to NaHCO in solution 3 The balance is less than 3kg;

[0027] 2) CO removal 2 The final saline-alkali mixture is evaporated and concentrated by MVR (Mechanical Vapor Recompression);

[0028] 3) When the sodium chloride in which the mixed solution is concentrated is close to saturation (sodium chloride saturation solubility 35.9g), the wet product Na is separated by crystallization of the cooling solution. 2 CO 3 Solid; the remaining mother liquor is evaporated twice by MVR. When the sodium carbonate in the evaporating liquid is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com