Anti-swelling shrinking agent and preparation method thereof

A technology of anti-swelling and shrinking agent and organic solvent, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc. Wetting reversal and other problems to achieve the effect of reducing capillary binding force, increasing water phase permeability, and reducing water injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] This embodiment also provides a kind of preparation method of anti-swelling agent, comprising the following steps:

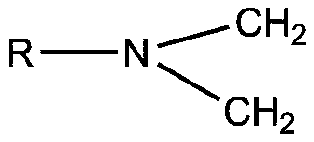

[0021] (1) Prepare materials according to the following parts by weight: 15.7-64.68 parts of tertiary amine, 6-13.3 parts of epichlorohydrin, 5-13.5 parts of hydrochloric acid, and 12-32 parts of organic solvent;

[0022] (2) Add tertiary amine, organic solvent and appropriate amount of deionized water into the reaction kettle and stir to mix evenly, then continue to stir the mixture and pass nitrogen gas to exhaust the oxygen in the reaction kettle, and drop hydrochloric acid into the reaction kettle at a uniform speed for mixing In the solution, since adding hydrochloric acid is an exothermic reaction, if the drop rate is too fast, the temperature of the mixed solution will be too high, and by-products will be produced. After dropping, raise the temperature of the mixture in the reactor to 60-80°C, and react for 4-6 hours;

[0023] (3) The mixed soluti...

Embodiment 1

[0027] This embodiment provides an anti-expansion and shrinkage agent, which includes the following raw materials in parts by weight: 42.6 parts of dodecyldimethyl tertiary amine, 10.2 parts of epichlorohydrin, 10 parts of hydrochloric acid, and 32 parts of ethanol.

[0028] The present embodiment also provides a preparation method of the above-mentioned anti-swelling and shrinking agent, comprising the following steps:

[0029] (1) material preparation: take by weighing 42.6g dodecyl dimethyl tertiary amine, 10.2g epichlorohydrin, 10g mass concentration are 37% hydrochloric acid and 32g ethanol;

[0030] (2) Add dodecyldimethyl tertiary amine, ethanol and 7g deionized water to a 250ml glass homogeneous reactor and stir to mix evenly, then continue to stir the mixed solution and feed nitrogen to exhaust the oxygen in the reactor, Drop hydrochloric acid into the mixed solution in the reaction kettle at a constant speed, and the speed of dropping hydrochloric acid is based on th...

Embodiment 2

[0033] This embodiment provides an anti-expansion and shrinkage agent, which includes the following raw materials in parts by weight: 64.68 parts of cetyl dimethyl tertiary amine, 13.3 parts of epichlorohydrin, 13.5 parts of hydrochloric acid, and 12 parts of methanol.

[0034] The present embodiment also provides a preparation method of the above-mentioned anti-swelling and shrinking agent, comprising the following steps:

[0035] (1) material preparation: take by weighing 64.68g cetyl dimethyl tertiary amine, 13.3g epichlorohydrin, 13.5g mass concentration are 37% hydrochloric acid and 12g methanol;

[0036] (2) Add hexadecyldimethyl tertiary amine, methanol and 4g deionized water to a 250ml glass homogeneous reactor and stir to mix evenly, then continue to stir the mixed solution and feed nitrogen to exhaust the oxygen in the reactor, Drop hydrochloric acid into the mixed solution in the reactor at a constant speed, and the speed of dropping hydrochloric acid is based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com