Preparation method of zinc-nickel battery negative electrode silicate crystal material

A crystal material, zinc-nickel battery technology, applied in nickel storage batteries, battery electrodes, alkaline storage batteries, etc., can solve the problems of zinc anode material expansion and dendrite growth, etc., to achieve the effect of simple process, low cost and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add zinc chloride, stannous chloride, and calcium chloride into deionized water at 60°C according to the molar ratio of elements Zn:Sn:Ca=1.5:0.25:0.25 and stir until dissolved, then add 1M Na 2 SiO 3 Aqueous solution and keep the pH value of the mixed system at 9, after fully reacting for 2 hours, naturally cool and age for 6 hours to room temperature, filter, wash, dry and pulverize the precipitate at a temperature of 100°C to obtain the precursor of the target product.

Embodiment 2

[0015] Add zinc sulfate, stannous sulfate and calcium nitrate into deionized water at 60°C according to the ratio of element molar ratio Zn:Sn:Ca=1:0.5:0.5 and stir until dissolved, then add 1M Na 2 SiO 3 Aqueous solution and keep the pH value of the mixed system at 9, after fully reacting for 2 hours, naturally cool and age for 6 hours to room temperature, filter, wash, dry and pulverize the precipitate at a temperature of 100°C to obtain the precursor of the target product.

Embodiment 3

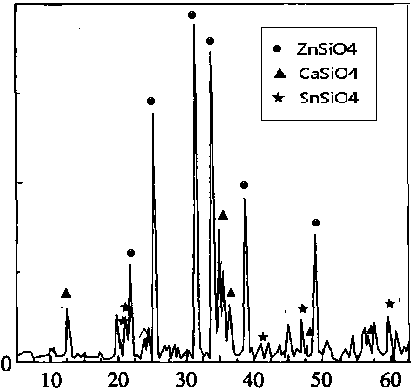

[0017] The silicate precursor crystal material obtained in Example 1 was placed in a muffle furnace for sintering at 850°C for 2 hours, and then cooled to room temperature with the furnace to obtain the target product silicate crystal material ZnCa 0.25 sn 0.25 SiO 4 , the sintered material is crushed and sieved for use.

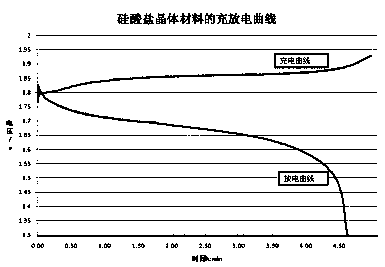

[0018] The ZnCa 0.25 sn 0.25 SiO 4 Add 5wt% conductive graphite to the silicate crystal material, use HPMC and SBR binder to prepare a slurry with a viscosity of about 10000cP and coat it on a density of 350g / m 2 On the nickel foam substrate, after drying and rolling, the tabs are spot-welded to form a negative electrode, and a negative electrode is sandwiched between two nickel hydroxide positive electrodes, and the positive and negative electrodes are separated by a diaphragm. In 7M KOH solution , after 300 charge-discharge cycles at a current of 0.2C, the measured capacity is 230mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com