Antibacterial preservative and preparation method thereof

A technology of preservatives and oxidants, which is applied in the field of antibacterial preservatives and their preparation, and can solve problems such as complex operations, limited sources, and unsatisfactory fresh-keeping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

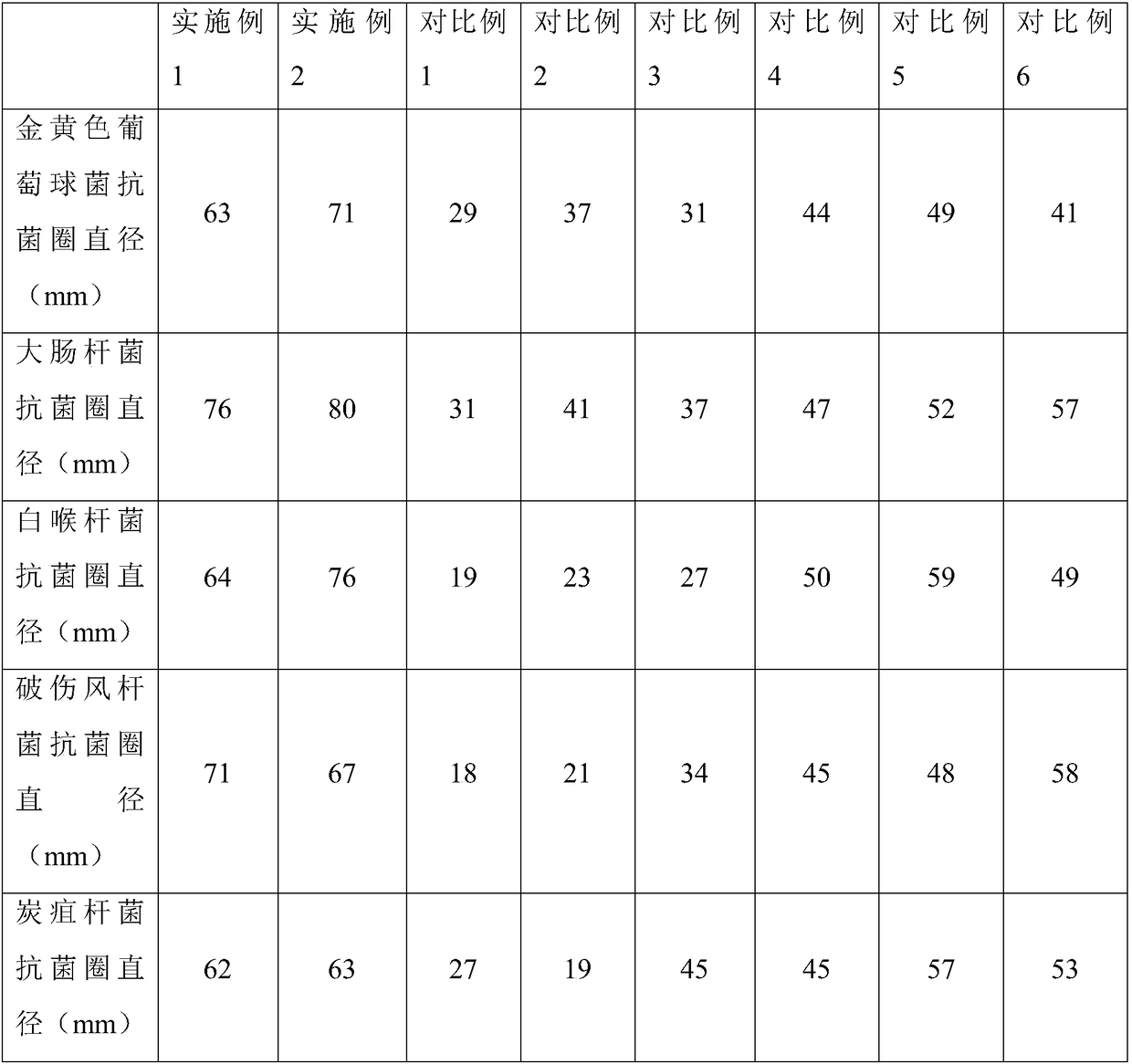

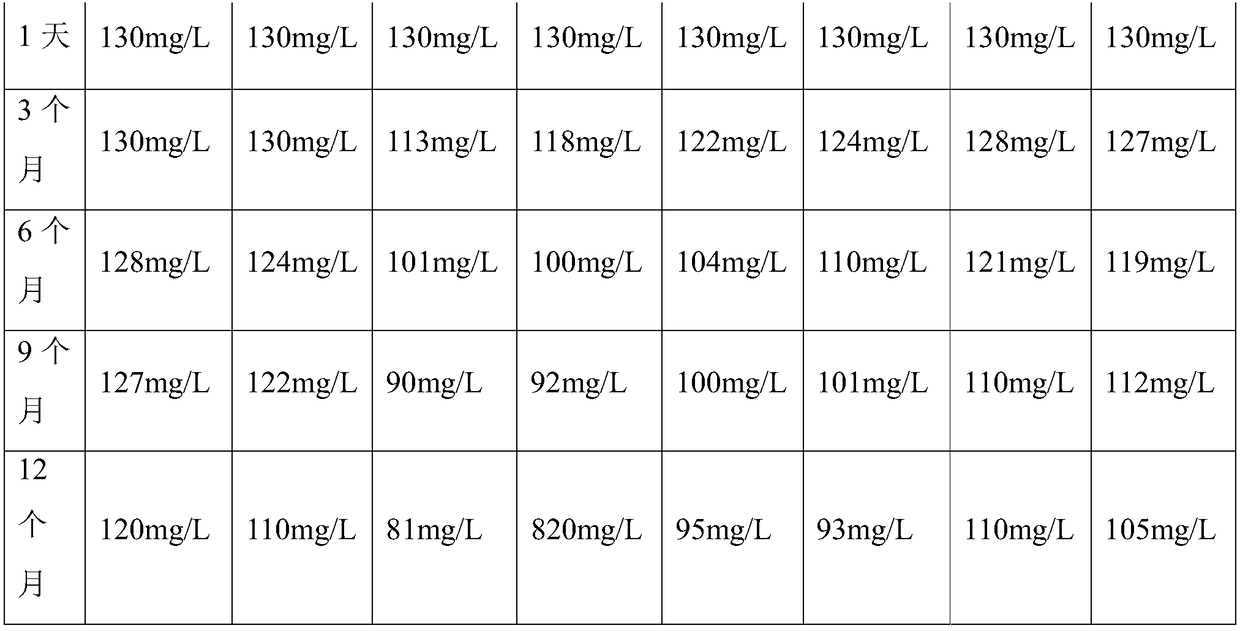

Examples

Embodiment 1

[0096] Methods as below:

[0097] (1) Preparation of gellan gum solution: Accurately weigh 100 mg of gellan gum powder, dissolve it in 10 mL of 2.5% sodium hydroxide solution, prepare a gellan gum solution with a final concentration of 1.0% (w / v), and boil to The solution was clear. Add 3 times the volume of isopropanol to precipitate, centrifuge at 8000r / min for 10min, take out the precipitate, and dry in an oven at 60°C until constant weight. Add distilled water to redissolve until the solution concentration is 0.1% (w / v), add 0.3g cation exchange resin and mix evenly for 30min, the resin is recovered by filtration with a sand core filter, and the filtrate is adjusted to neutrality with 2.5% sodium hydroxide solution to obtain the resultant cold glue solution;

[0098] (2) Preparation of oxidant mixture: Weigh 0.01 mmoL of 2,2,6,6-tetramethylpiperidine-1-oxyl radical powder and 0.1 mmoL of sodium bromide powder and dissolve them in 100 mL of distilled water. Add 7.5mmoL s...

Embodiment 2

[0105] Methods as below:

[0106] (1) Preparation of gellan gum solution: Accurately weigh 200 mg of gellan gum powder, dissolve it in 10 mL of 2.5% sodium hydroxide solution, prepare a gellan gum solution with a final concentration of 2% (w / v), and boil to The solution was clear. Add 4 times the volume of isopropanol to precipitate, centrifuge at 10,000 r / min for 20 minutes, take out the precipitate, and dry in an oven at 80°C until constant weight. Add distilled water to redissolve until the solution concentration is 0.2% (w / v), add 0.5g cation exchange resin and mix evenly for 30min, the resin is recovered by filtration with a sand core filter, and the filtrate is adjusted to neutrality with 2.5% sodium hydroxide solution to obtain the resultant cold glue solution;

[0107] (2) Preparation of oxidant mixture: Weigh 0.03 mmoL of 2,2,6,6-tetramethylpiperidine-1-oxyl radical powder and 0.2 mmoL of sodium bromide powder and dissolve them in 200 mL of distilled water. Add 12m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com