Integrated system and method for multi-stage white-smoke-removing and purification of flue gas and waste heat recycling

A waste heat recovery and flue gas technology, applied in the field of integrated systems, can solve the problems of high absorbent consumption, low COP value, pipeline clogging and scouring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

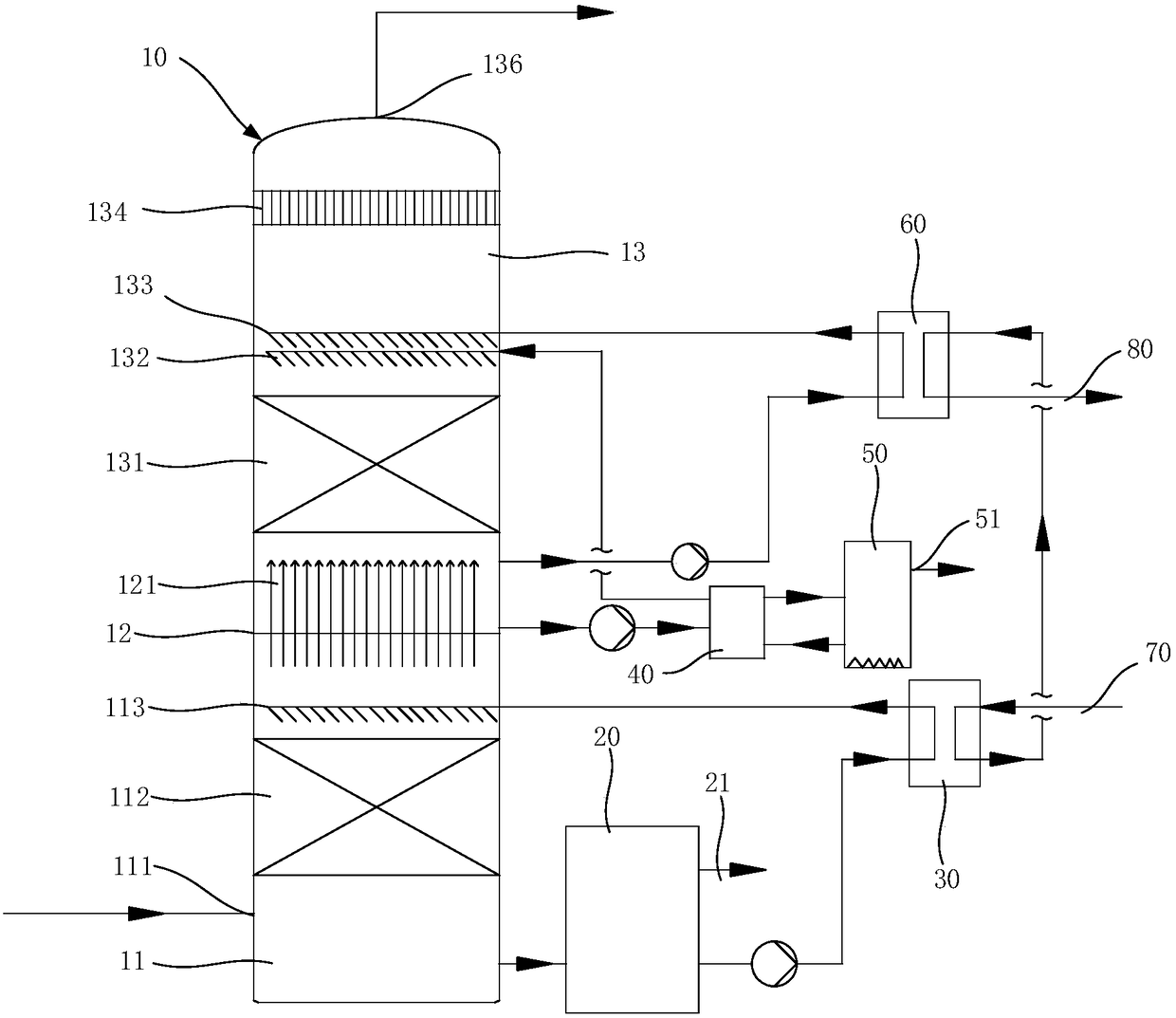

[0080] 1. An integrated system for multi-stage dewhitening and purification of flue gas and waste heat recovery

[0081] Such as figure 1 The integrated system for multi-stage dewhitening and purification of flue gas and waste heat recovery is shown. The integrated system includes a multi-stage absorption tower 10, a primary absorption liquid storage tank 20, a primary solution heat exchanger 30, a secondary solution external Circulating heat exchanger 40, secondary solution self-circulating heat exchanger 60 and secondary solution regeneration device 50;

[0082] The number of stages of the multi-stage absorption tower 10 is more than two, and the multi-stage absorption tower 10 is divided into a primary absorption zone 11 and a secondary absorption zone 13 from bottom to top; the multi-stage absorption tower 10 is provided with a wet flue gas inlet 111, The wet flue gas inlet 111 is used to send the wet flue gas into the primary absorption zone 11; Bit stability;

[0083]...

Embodiment 2

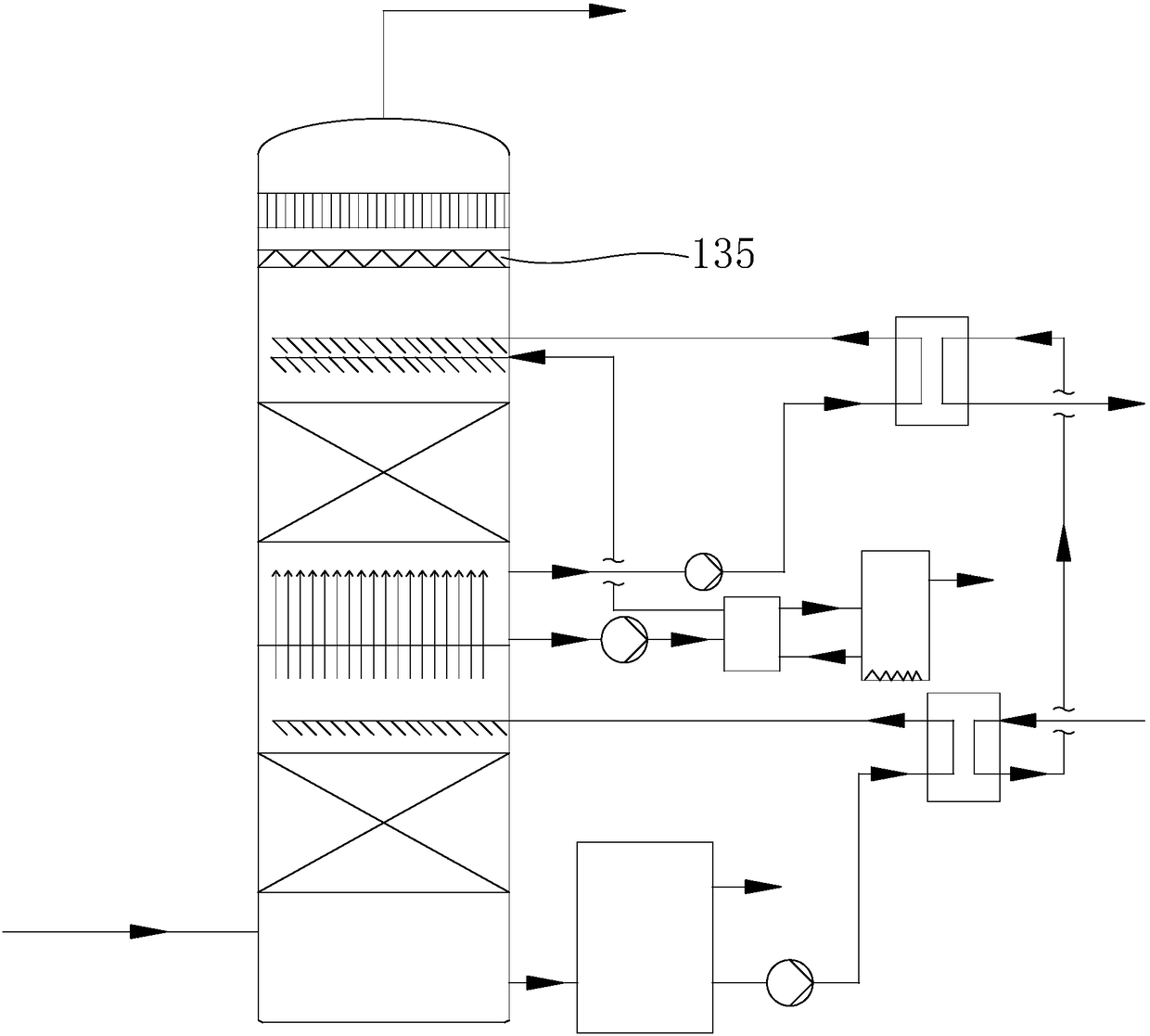

[0109] 1. An integrated system for multi-stage dewhitening and purification of flue gas and waste heat recovery

[0110] Such as figure 2 In the integrated system shown, there is also a wet electrostatic precipitator 135 above the secondary absorption zone 13 in the multi-stage absorption tower 10, and the rest are the same as the integrated system of Embodiment 1.

[0111] 2. Methods of flue gas dewhitening and purification and waste heat recovery

[0112] A method of flue gas dewhitening purification and waste heat recovery using the above-mentioned integrated system, the steps of the method are the same as those in Example 1, and the process parameters are slightly different, as follows:

[0113] In step (1), the inlet temperature of wet flue gas is 80°C, and the inlet flow rate of wet flue gas is 125000Nm 3 / h; the primary solution is 5wt% NaCl aqueous solution, the inlet temperature of the primary solution is 40°C, and the circulation flow rate of the primary solution ...

Embodiment 3

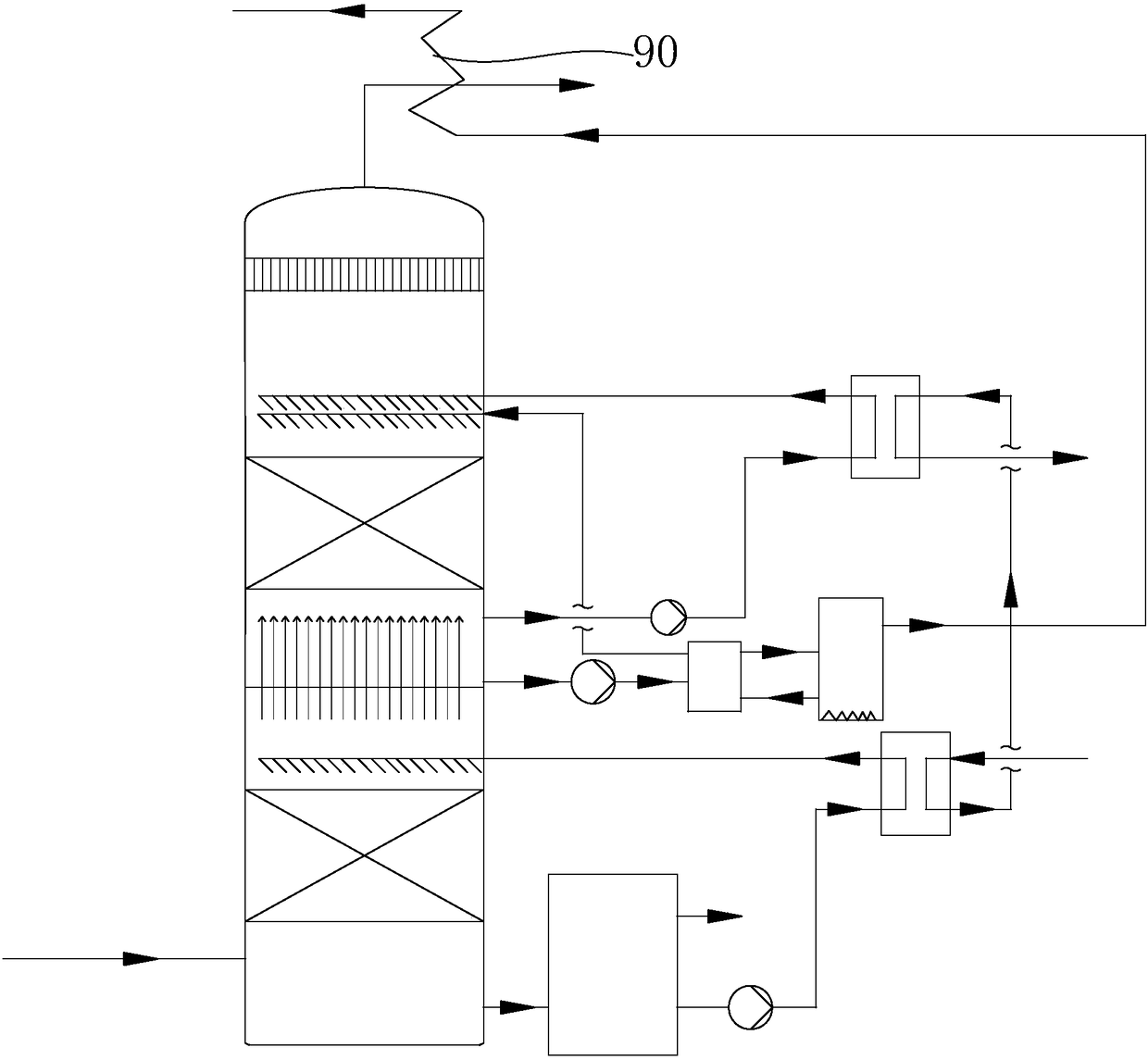

[0117] 1. An integrated system for multi-stage dewhitening and purification of flue gas and waste heat recovery

[0118] Such as image 3 In the integrated system shown, the integrated system is also provided with a first dry flue gas outlet 136 pipe leading from the dry flue gas outlet 136, and a flue gas heater 90 is arranged on the first dry flue gas outlet 136 pipe, and the flue gas The heater 90 is used to heat the dry flue gas; the secondary solution generator is also provided with a secondary steam outlet 51, and the secondary steam outlet 51 communicates with the thermal fluid channel of the flue gas heater 90, and the rest are the same as the integrated system of embodiment 1 .

[0119] 2. Methods of flue gas dewhitening and purification and waste heat recovery

[0120] A method of flue gas dewhitening purification and waste heat recovery using the above-mentioned integrated system, the steps of the method are the same as those in Example 1, and the process paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com