Preparation method for glass material stock and glass

A technology for glass frit and glass batch material, which is applied in the field of glass blank and glass preparation, and can solve the problems of easy flying agglomeration, refractory lumps, stones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the glass of one embodiment, comprises the following steps:

[0023] Step S110, preparing a glass blank.

[0024] In one of the embodiments, the preparation of the glass blank comprises:

[0025] Step S111, drying the silica powder.

[0026] In one embodiment, the particle size of the silicon dioxide powder is less than 0.15mm, preferably, the particle size of the silicon dioxide powder is 0.05mm-0.1mm. In this embodiment, the ultrafine silica powder can be effectively used to prepare glass, which saves energy and solves the problem that the ultrafine silica powder is difficult to use. Of course, the silica powder in the batch is not limited to ultrafine silica powder. Silica powder, silicon dioxide powder of other particle size can be used.

[0027] In order to effectively utilize ultra-fine silica powder, the silica powder can be sieved first, and the silica powder with a particle size of less than 0.15mm can be selected.

[0028] Step S1...

Embodiment 1~10

[0061] In the following examples, the amount of each component is the mass content.

[0062] The preparation method of the glass of embodiment 1~10 comprises the following steps:

[0063] 1. After crushing industrial silica, sieve out superfine powder with particle size less than 0.15mm. The crushing machine adopts non-ferrous hammer head, and the iron content of silica powder is 80ppm.

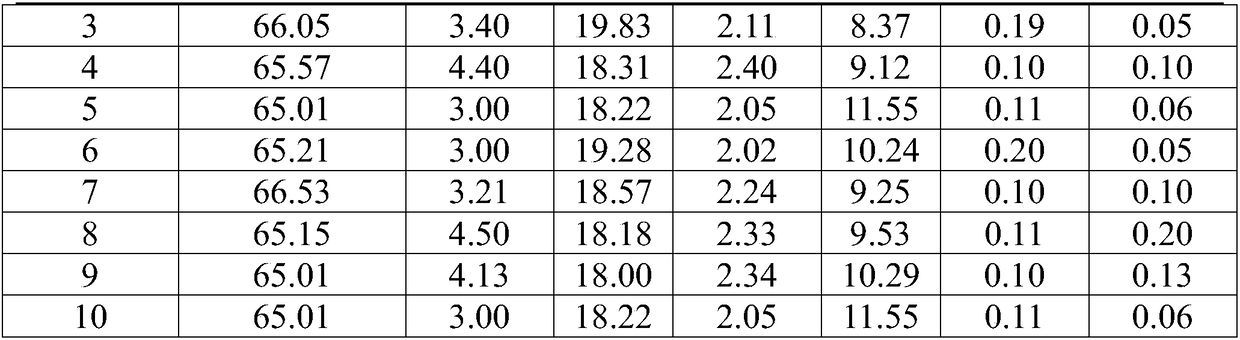

[0064] 2. Weigh silica powder, alumina, boric acid, limestone, soda ash, sodium nitrate, and cerium oxide according to the ingredients in Table 1, and mix them with a mixer for 10 to 30 minutes to obtain a mixture.

[0065] Table 1

[0066]

[0067]

[0068] Note: The numerical value corresponding to each raw material in Table 1 is its mass percentage content.

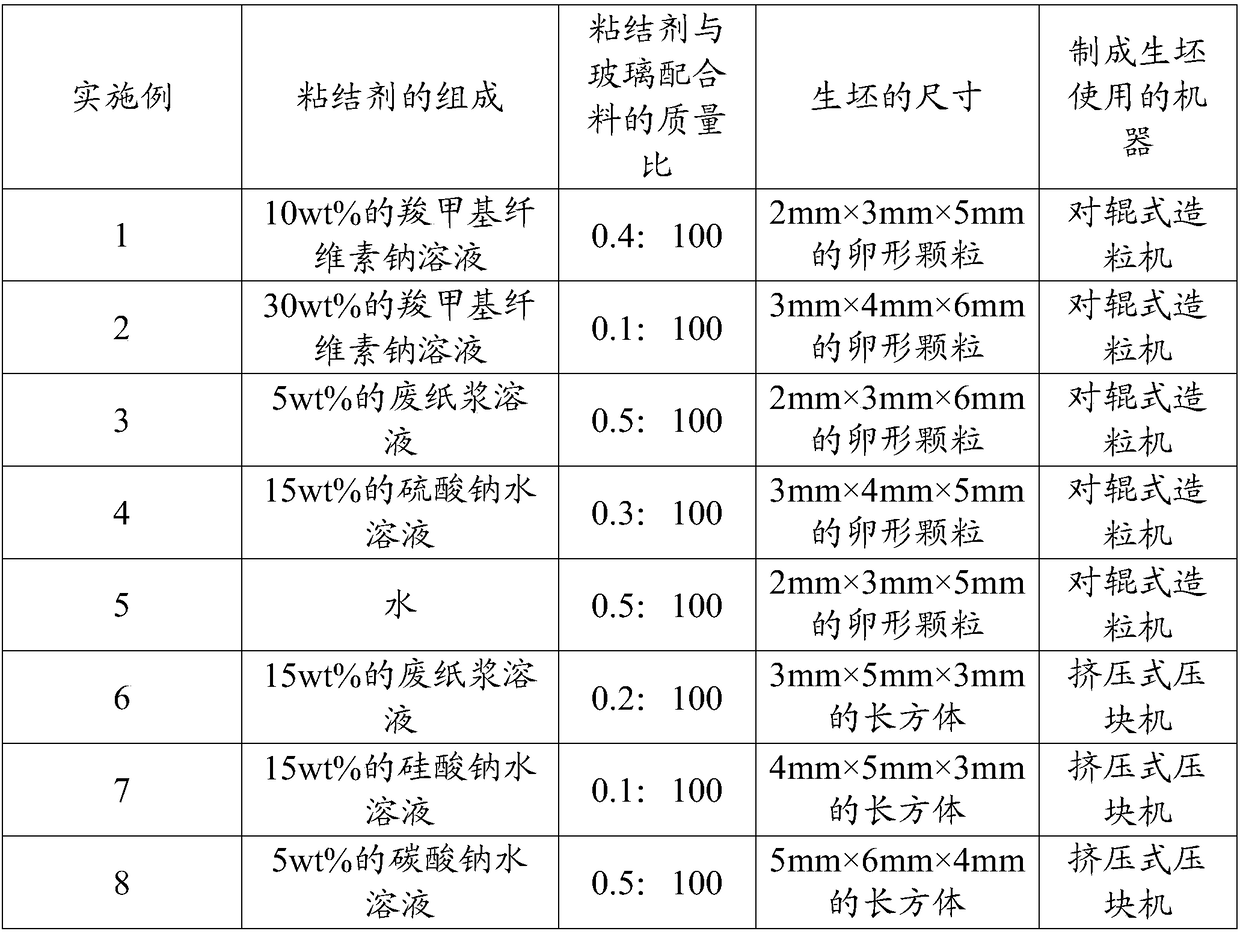

[0069] 3. Mix the glass batch materials of Examples 1-8 with the binder to obtain a premixed material, and use a machine to make the premixed material into a green body. Please refer to Table 2 for the composition of the bind...

Embodiment 1

[0081] The ultrafine silica powder in Examples 1-8 is granulated before being put into the melting furnace, which greatly reduces the generation of dust during production. Observation under a stereomicroscope found that there were almost no defects such as stones, streaks, and bubbles in the glass tubes prepared in Examples 1-8, indicating that the preheating treatment of the granulated batch materials effectively improved the melting and clarifying effects of the glass. The raw material composition of embodiment 1 is the same as that of embodiment 9, and the raw material composition of embodiment 5 is the same as that of embodiment 10. As can be seen from table 4, the volatilization amount of sodium oxide is reduced to 2.54% and 2.66% by 3.51% and 3% respectively , the volatile amount of boron oxide decreased from 11.93% and 11.99% to 7.81% and 7.84% respectively. Compared with the traditional process, the chemical composition of the glass tube prepared by the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com