Medical-grade PVC (polyvinyl chloride) cable material and preparation technique thereof

A cable material, medical-grade technology, applied in the field of medical-grade PVC cable material and its preparation process, can solve the problems of poor electrical performance, large frictional resistance, poor environmental performance, etc., and achieve good mechanical and physical properties, excellent processing performance, and environmental protection good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

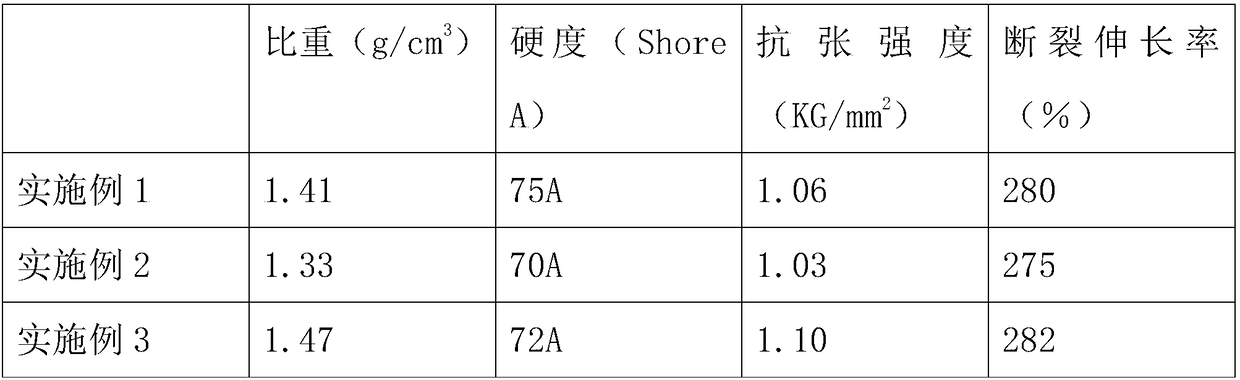

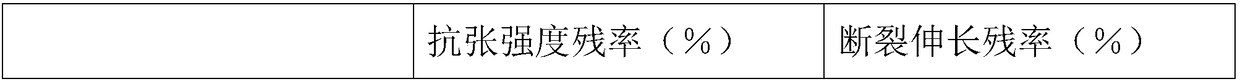

Embodiment 1

[0028] The invention discloses a medical-grade PVC cable material, which is prepared from the following components in parts by weight: 100 parts of PVC resin, 50 parts of calcium carbonate, 80 parts of plasticizer, 5 parts of Ca and Zn composite stabilizer, 6 parts of flame retardant, 0.5 parts of lubricant, 2 parts of additives, 5 parts of pigment.

[0029] The plasticizer adopts TOTM, the flame retardant adopts Mg(OH)2, the described lubricant adopts 380C, the described auxiliary agent adopts CaST, the described pigment adopts R900, and the described Ca, Zn composite stabilizer adopts OW-5102.

[0030] The present invention also discloses a preparation process of the above-mentioned medical-grade PVC cable material, and the specific steps are as follows:

[0031] (1), according to the above-mentioned parts by weight, open the cylinder head, first add calcium carbonate, then add PVC resin, then add auxiliary agent, pigment;

[0032] (2) Start the powder mixing motor, adjust...

Embodiment 2

[0037] The invention discloses a medical-grade PVC cable material, which is prepared from the following components in parts by weight: 90 parts of PVC resin, 55 parts of calcium carbonate, 75 parts of plasticizer, 8 parts of Ca and Zn composite stabilizer, 2 parts of flame retardant, 0.9 parts of lubricant, 1 part of additive, 8 parts of pigment.

[0038] The plasticizer adopts TOTM, the flame retardant adopts Mg(OH)2, the described lubricant adopts 380C, the described auxiliary agent adopts ZNST, the described pigment adopts K2270, and the described Ca, Zn composite stabilizer adopts OW-5102.

[0039] The present invention also discloses a preparation process of the above-mentioned medical-grade PVC cable material, and the specific steps are as follows:

[0040] (1), according to the above-mentioned parts by weight, open the cylinder head, first add calcium carbonate, then add PVC resin, then add auxiliary agent, pigment;

[0041] (2) Start the powder mixing motor, adjust t...

Embodiment 3

[0046] The invention discloses a medical-grade PVC cable material, which is prepared from the following components in parts by weight: 110 parts of PVC resin, 45 parts of calcium carbonate, 85 parts of plasticizer, 2 parts of Ca and Zn composite stabilizer, 10 parts of flame retardant, 0.1 part of lubricant, 3 parts of auxiliary agent, 2 parts of pigment.

[0047] The plasticizer adopts TOTM, the flame retardant adopts Mg(OH) 2, the described lubricant adopts 380C, the described auxiliary agent adopts ZNST, the described pigment adopts 5008, and the described Ca, Zn composite stabilizer adopts OW-5102.

[0048]The present invention also discloses a preparation process of the above-mentioned medical-grade PVC cable material, and the specific steps are as follows:

[0049] (1), according to the above-mentioned parts by weight, open the cylinder head, first add calcium carbonate, then add PVC resin, then add auxiliary agent, pigment;

[0050] (2) Start the powder mixing motor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com