Electrochemical sensor for determining 2,4,6-trichlorophenol as well as preparation and application of electrochemical sensor

A trichlorophenol, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, instruments, etc., to achieve the effect of improving anti-interference ability, low cost, strong specific recognition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

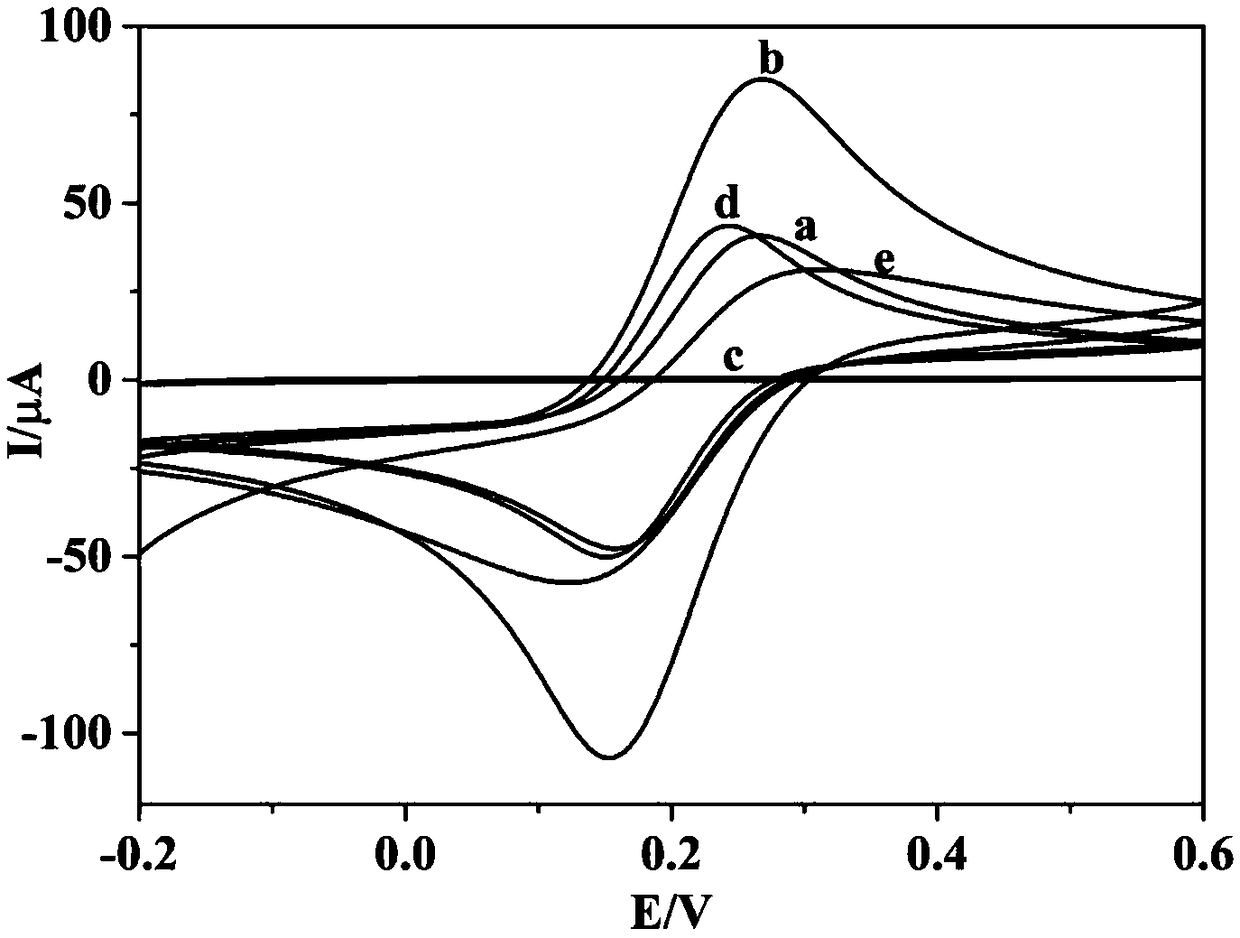

[0021] Preparation of the sensor:

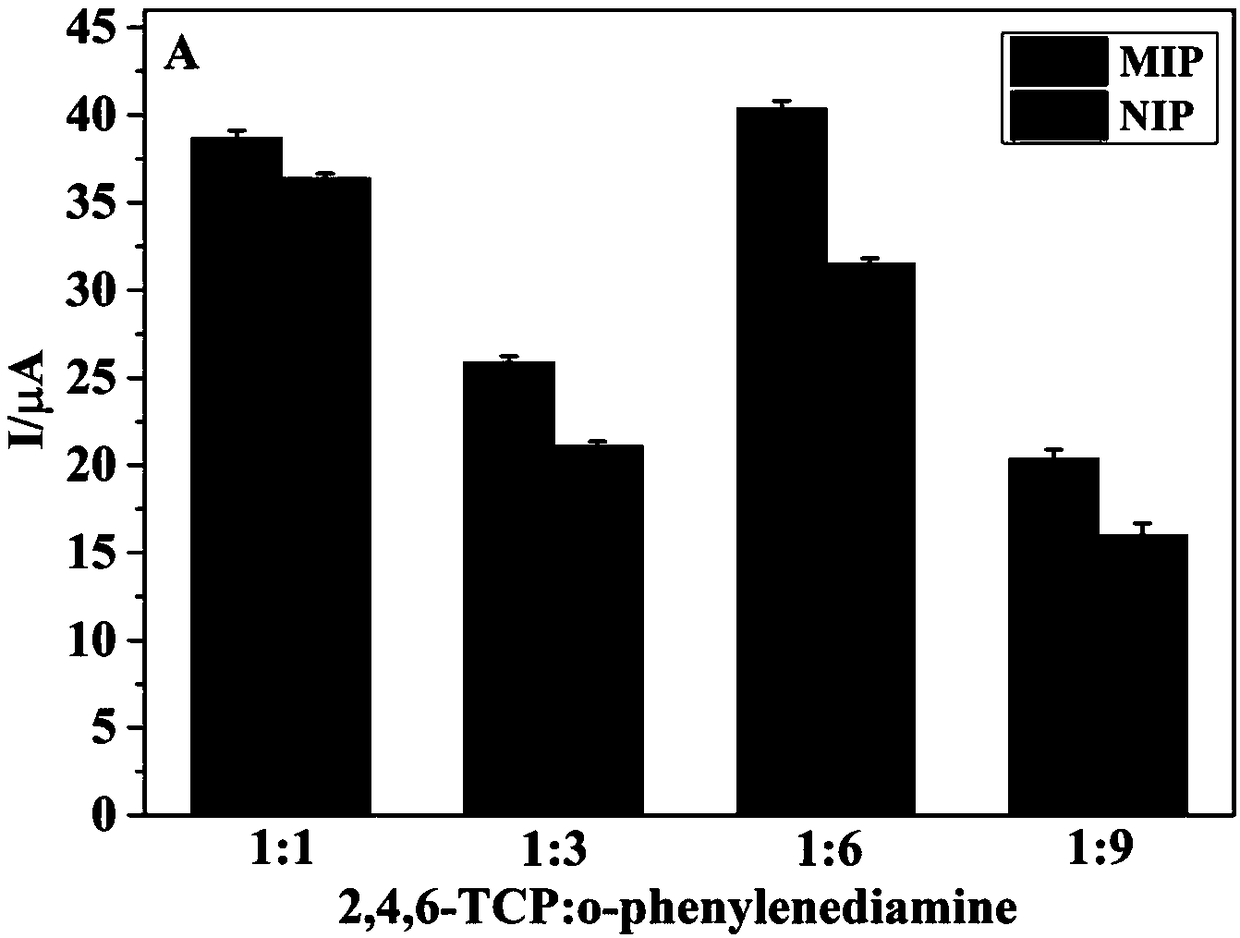

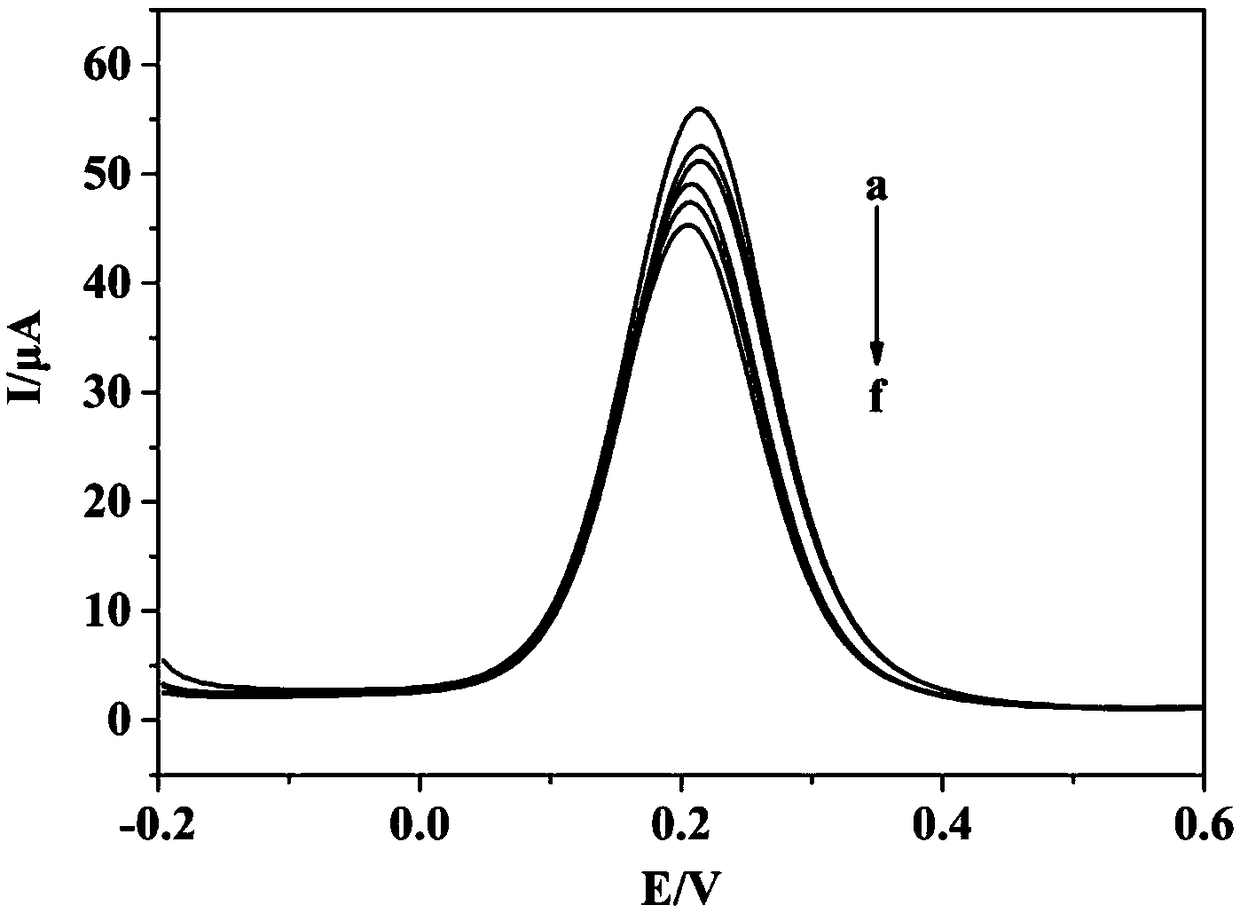

[0022] Take a total of 5 μL (volume ratio of 3:1) of a mixed solution of carbon quantum dot solution with a volume concentration of 4% dispersed in distilled water and a mass concentration of 1% chitosan acetic acid solution, and drop-coat it on the surface of the polished bare glassy carbon electrode. Tumble dry under infrared lamps. After placing it in a mixed solution of 1mM 2,4,6-TCP ethanol-water solution and 1mM o-phenylenediamine ethanol-water solution (the molar ratio is 1:1), the pH of the solution was adjusted to 5 with 0.05M phosphate buffer solution. In the range of 1.0V, the cyclic voltammetry was scanned for 20 cycles at a scan rate of 50mV / s, and the electrochemical polymerization was formed into a film. After the polymeric film was naturally dried at room temperature, the electrode prepared above was scanned by cyclic voltammetry in a 1% (m / V) NaOH solution for 6 laps at the same scan rate in the potential range of 0-1.5V, a...

Embodiment 2

[0024] Preparation of the sensor:

[0025] Take a total of 9 μL of a mixed solution of a carbon quantum dot solution with a volume concentration of 4% dispersed in distilled water and a mass concentration of 1% chitosan acetic acid solution (volume ratio is 3:1), and drop-coat it on the surface of the polished bare glassy carbon electrode. Tumble dry under infrared lamps. After placing it in a mixed solution of 1mM 2,4,6-TCP ethanol-water solution and 6mM o-phenylenediamine ethanol-water solution (molar ratio 1:6), adjust the pH of the solution to 7 with 0.05M phosphate buffer, and adjust the pH of the solution to 7 at 0- In the range of 1.0V, the cyclic voltammetry was scanned for 20 cycles at a scan rate of 50mV / s, and the electrochemical polymerization was formed into a film. After the polymeric film was naturally dried at room temperature, the electrode prepared above was scanned by cyclic voltammetry in a 1% (m / V) NaOH solution for 6 laps at the same scan rate within the...

Embodiment 3

[0027] Preparation of the sensor:

[0028] Take a total of 9 μL of a mixed solution of a carbon quantum dot solution with a volume concentration of 4% dispersed in distilled water and a mass concentration of 1% chitosan acetic acid solution (volume ratio is 3:1), and drop-coat it on the surface of the polished bare glassy carbon electrode. Tumble dry under infrared lamps. After placing it in a mixed solution of 1mM 2,4,6-TCP ethanol solution and 6mM pyrrole ethanol solution (the molar ratio is 1:6), adjust the pH of the solution to 7 with 0.05M phosphate buffer solution, within the range of 0-1.0V, Electrochemical polymerization was performed under the conditions of 20 cycles of cyclic voltammetry scanning at a scan rate of 50 mV / s. After the polymeric membrane is naturally dried at room temperature, the template molecules are eluted with the same scan rate of 1% (m / V) NaOH solution as the eluent within the potential range of 0-1.5V for the electrode prepared above. After dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com