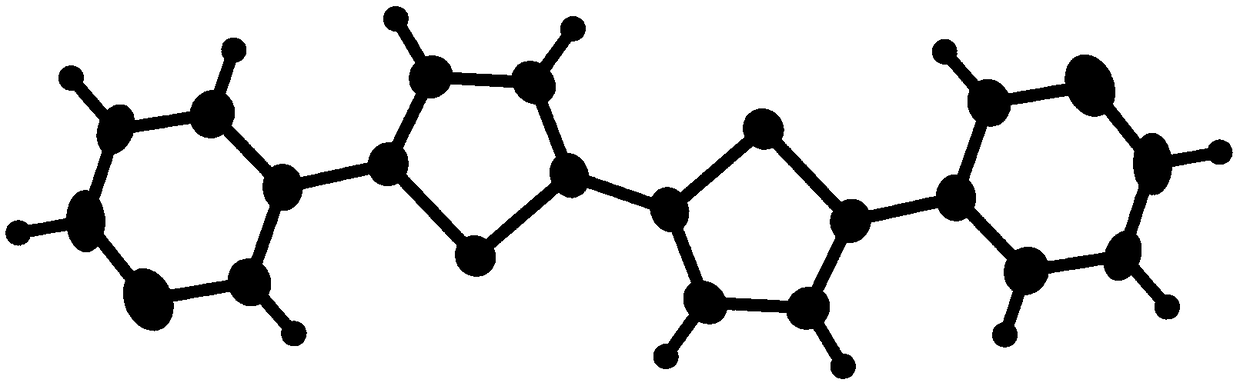

Bipyridine bisthiophene blue fluorescent material

A technology of bispyridine bisthiophene and pyridine bisthiophene, which is applied in the field of bispyridine bisthiophene organic light-emitting materials, can solve the problems of harsh preparation conditions, cumbersome synthesis steps, and expensive preparation, and achieve large delocalization, simple synthesis steps, The effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 5,5'-dibromo-2,2'-dithiophene (0.325g 1.0mmol), 3-pyridineboronic acid (0.271g 2.2mmol), tetrakistriphenylphosphine palladium (0.058g 0.03mmol) and potassium carbonate ( 1.658g 12mmol) was mixed in a 100mL reaction device, and the reaction device was evacuated and nitrogen was passed through, and the operation was repeated three times, then a mixed solution of toluene 18mL, ethanol 9mL, and water 3mL was added, and the reaction was refluxed at 85°C under the protection of nitrogen gas. sky. After the reaction was completed, the liquids were cooled and separated, extracted with dichloromethane, the organic phases were combined, washed with saturated brine and dried over magnesium sulfate to remove water. The solvent was removed by a rotary evaporator to obtain a solid powder, which was then separated through a column with an eluent of petroleum ether: ethyl acetate = 1:1 (volume ratio) to obtain a light yellow solid powder.

Embodiment 2

[0022] Take 5,5'-dibromo-2,2'-dithiophene (0.325g 1.0mmol), 3-pyridineboronic acid (0.307g 2.5mmol), tetrakistriphenylphosphine palladium (0.046g 0.04mmol) and potassium carbonate ( 1.935g 14.0mmol) was mixed in a 100mL reaction device, and the reaction device was vacuumed and nitrogen was passed through, and the operation was repeated three times, then a mixture of toluene 30mL, ethanol 15mL, and water 5mL was added, and the reaction was refluxed at 85°C under the protection of nitrogen. 2.5 days. After the reaction was completed, the liquids were cooled and separated, extracted with dichloromethane, the organic phases were combined, washed with saturated brine and dried over magnesium sulfate to remove water. The solvent was removed by a rotary evaporator to obtain a solid powder, which was then separated through a column with an eluent of petroleum ether: ethyl acetate = 1:1 (volume ratio) to obtain a light yellow solid powder.

Embodiment 3

[0024]Take 5,5'-dibromo-2,2'-dithiophene (0.650g 2.0mmol), 3-pyridineboronic acid (0.738g 6.0mmol), tetrakistriphenylphosphine palladium (0.116g 0.1mmol) and potassium carbonate ( 2.764g 20mmol) was mixed in a 100mL reaction device. After the reaction device was vacuumed, nitrogen gas was passed, and the operation was repeated three times. Then, a mixed solution of 36 mL of toluene, 18 mL of ethanol, and 6 mL of water was added, and the reaction was refluxed at 85 ° C under the protection of nitrogen gas. sky. After the reaction was completed, the liquids were cooled and separated, extracted with dichloromethane, the organic phases were combined, washed with saturated brine and dried over magnesium sulfate to remove water. The solvent was removed by a rotary evaporator to obtain a solid powder, which was then separated through a column with an eluent of petroleum ether: ethyl acetate = 1:1 (volume ratio) to obtain a light yellow solid powder.

[0025] The substances participa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com