Water-based composite adhesive and method for making holographic positioning transfer paper

A production method and transfer paper technology, applied in the direction of copying/marking method, adhesive, temperature recording method, etc., can solve the problems of high cost, high material consumption, long production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

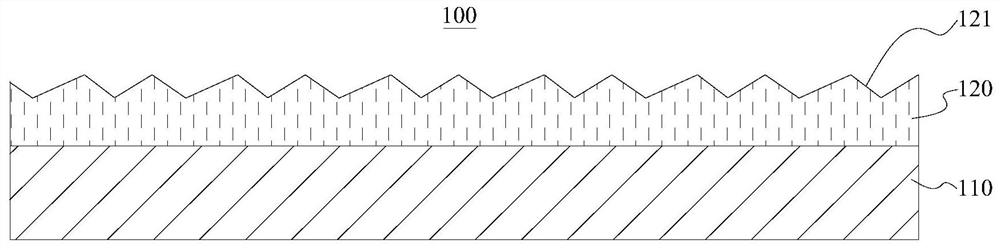

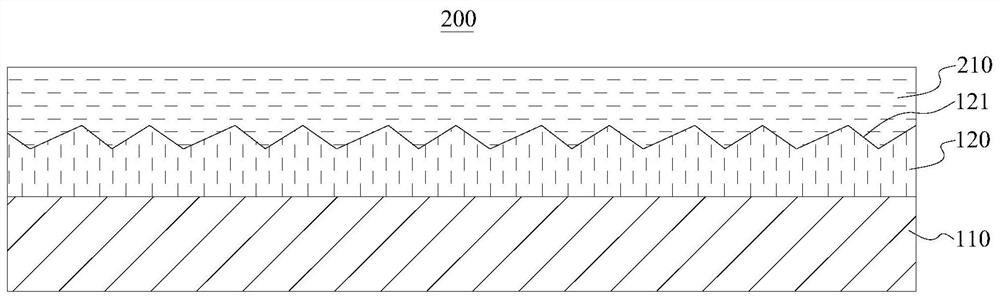

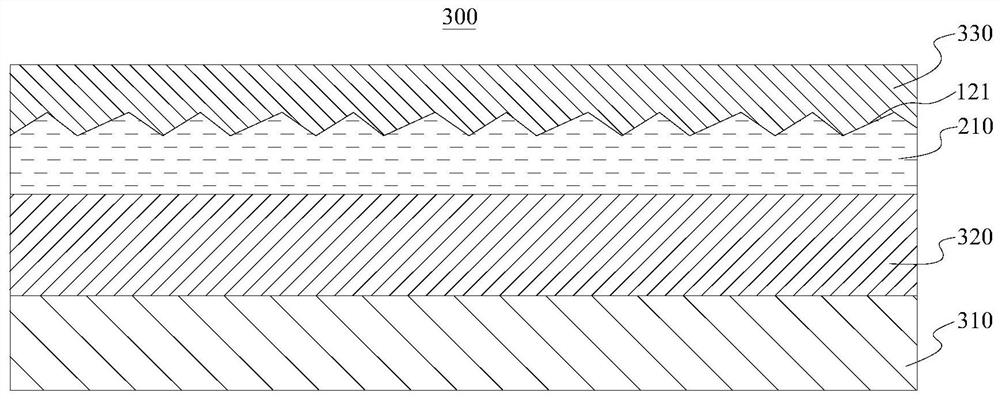

[0051] see Figure 1 to Figure 3 As shown, this embodiment provides a holographic positioning transfer paper 300, which includes a paper base 310, a composite adhesive layer 320, an aluminum-coated layer 210, and a protective layer 330 that are stacked sequentially from bottom to top. The upper surface of the aluminum-coated layer 210 is set There is a holographic microstructure 121, the thickness of the composite adhesive layer 320 is 3 μm; the thickness of the aluminum layer 210 is 250 angstroms; the thickness of the protective layer 330 is 0.5 μm. The specific production method of the holographic positioning transfer paper 300 is as follows:

[0052] S1. Making holographic positioning composite film 100: PET film is used as the base film layer 110, corona the surface of the base film layer 110 to make the surface tension reach 48dyn / cm; apply imaging paint on the corona surface of the base film layer 110, and mold the hologram microstructure 121, forming a positioning holo...

Embodiment 2

[0058] Please refer to image 3 As shown, this embodiment provides a holographic positioning transfer paper 300, the manufacturing method of the holographic positioning transfer is roughly the same as that of Embodiment 1, the difference lies in:

[0059] In this embodiment, the thickness of the aluminized layer 210 of the holographic positioning transfer paper 300 is 300 angstroms, and the thickness of the composite adhesive layer 320 is 1 μm. The water-based composite glue is formed from the following raw materials in parts by weight: 60 parts of acrylate emulsion; 4 parts of polyoxyethylene ether; 2 parts of sodium sulfosuccinate; 3 parts of hexamethylenediamine; 0.3 parts of cellulose; 30 parts of ethanol. Among them, the acrylate emulsion is made of the following raw materials in parts by weight: 15 parts of methyl methacrylate; 25 parts of butyl acrylate; 8 parts of hydroxyethyl acrylate; 4 parts of vinyl sulfonate; 0.3 parts; 43 parts of deionized water.

Embodiment 3

[0061] Please refer to image 3 As shown, this embodiment provides a holographic positioning transfer paper 300, the manufacturing method of the holographic positioning transfer is roughly the same as that of Embodiment 1, the difference lies in:

[0062] In this embodiment, the thickness of the aluminum-coated layer 210 of the holographic positioning transfer paper 300 is 350 angstroms. The water-based composite glue is specifically made of the following raw materials in parts by weight: 40 parts of acrylate emulsion; 3 parts of polyoxyethylene ether; 1 part of sodium sulfosuccinate; 5 parts of adipic acid dihydrazide; 1 part of polydimethylsiloxane; 55 parts of water. Among them, the acrylate emulsion is made of the following raw materials in parts by weight: 30 parts of styrene; 12 parts of isooctyl acrylate; 10 parts of hydroxypropyl acrylate; 1 part of polyoxyethylene octylphenyl ether; 1 part of ammonium; 61 parts of deionized water.

[0063] In summary, the water-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com