A micro-chamber microfluidic system for microbial growth image detection

A microfluidic system and image detection technology, applied in the field of microbial detection, can solve the problems of limiting microbial movement, microbial contact with culture medium, unfavorable microbial growth, microbial growth and movement restrictions, etc., to achieve true and reliable data, accurate measurement, The effect of less sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

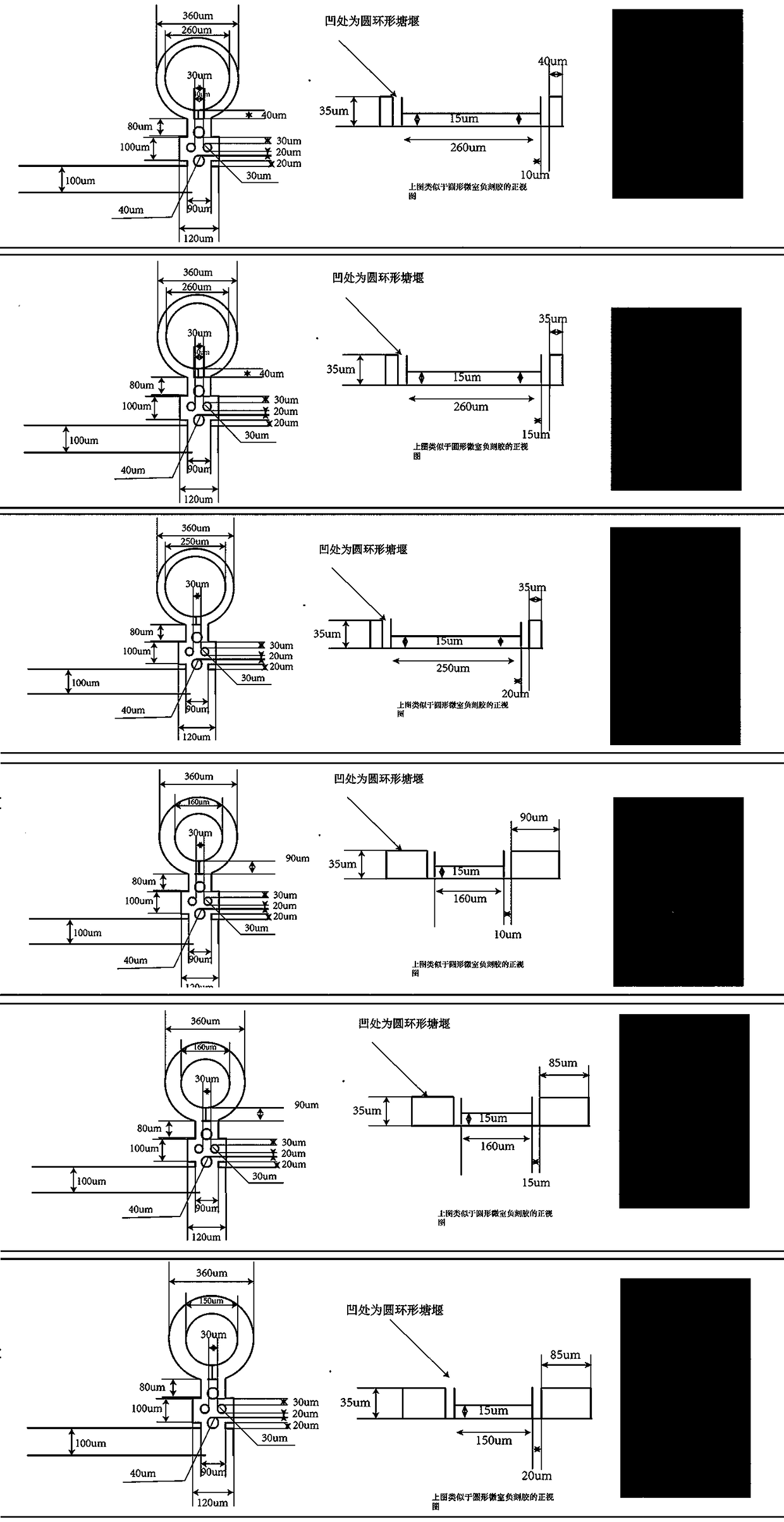

[0063] Such as Figure 1~4 As shown, this embodiment discloses a microchamber microfluidic chip for real-time culture and observation of microorganisms. The microfluidic chip includes a chip body and a PDMS membrane integrally molded with it. The chip body contains 4 strips A microfluidic channel, the microfluidic channel is composed of a liquid inlet 1, a main channel 2 and a liquid outlet 3 connected in sequence; the middle part of the main channel 1 is the microchamber area of the microfluidic chip, and the main channel The middle section of 1 is a broken line, and the angles between each other are all 90°. The broken line main channel extends outward along the liquid flow direction at the corner to form an annular channel and a microchamber 4 with a cofferdam structure. 4. A T-shaped corner 5 is arranged at one end close to the main channel; a microcolumn 6 is arranged on the channel between the microchamber 4 and the main channel 1; the cofferdam of the microchamber 4 i...

Embodiment 2

[0072] Such as Image 6 As shown, this embodiment discloses a microchamber microfluidic system for microbial growth image detection, including a microscope, a constant flow syringe pump, a syringe, a constant temperature stage, the microchamber microfluidic chip described in Example 1, and a collector , CMOS video detection components, video recorder, mobile hard disk and display; the constant temperature stage is placed on the microscope carrier; the microchamber microfluidic chip is placed on the constant temperature stage to provide constant culture for the chip The temperature and size are adapted to the microscope and the chip; the CMOS video detection component is fixed above the microscope through connection, and the CMOS video detection component is used to measure the morphology of bacteria in each microchamber in the microchamber microfluidic chip Change; the liquid inlet of the microchamber microfluidic chip is connected with a constant flow syringe pump, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com