Pore wall laser peening compound expansion strengthening device and method thereof

A composite extrusion and laser shot peening technology, applied in the field of laser shot peening technology or extrusion strengthening, can solve the problems of reducing the strengthening effect of the hole wall, consuming energy, and the strengthening effect is not obvious, so as to avoid the fracture of the mandrel. and scratches on the hole wall, reducing the effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

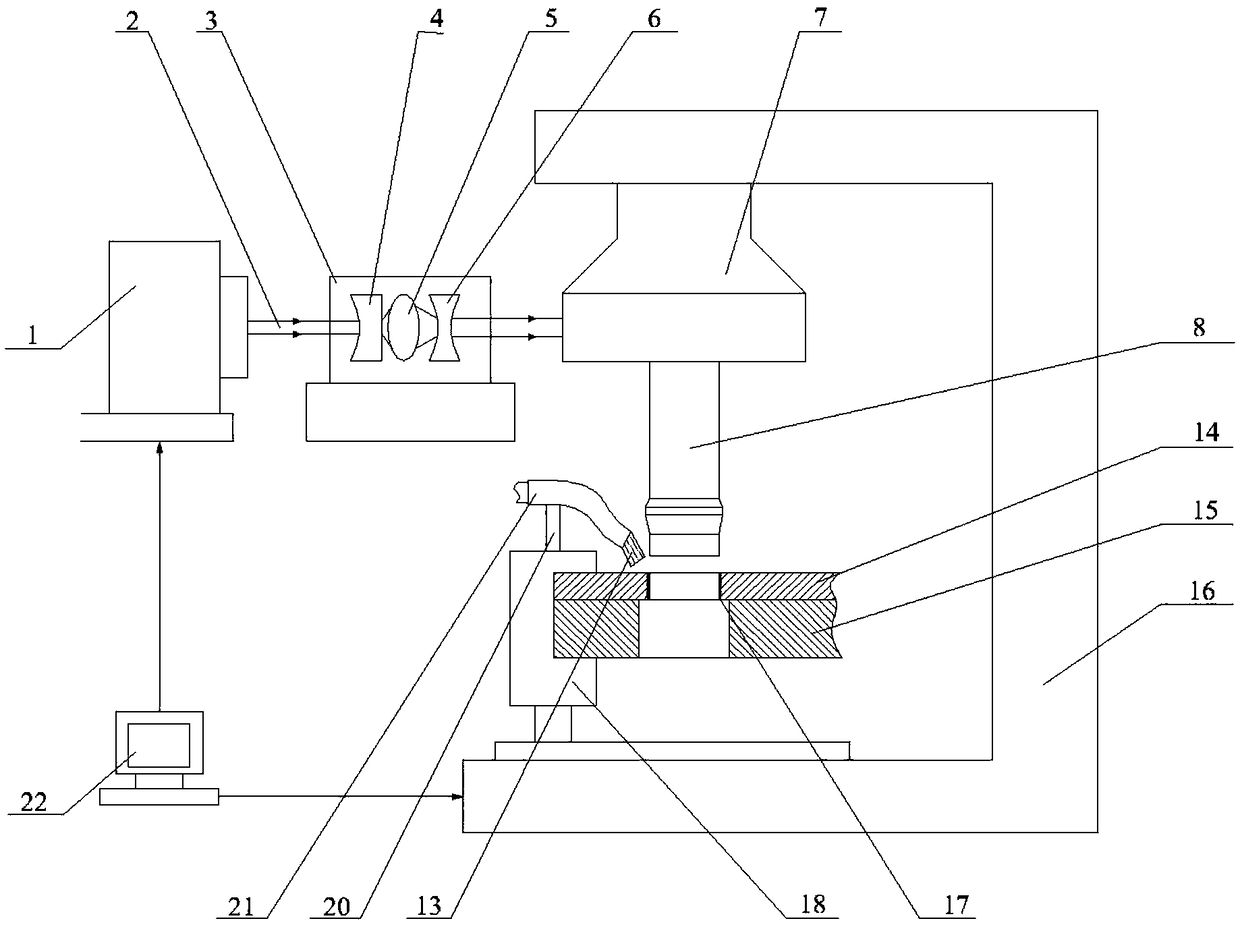

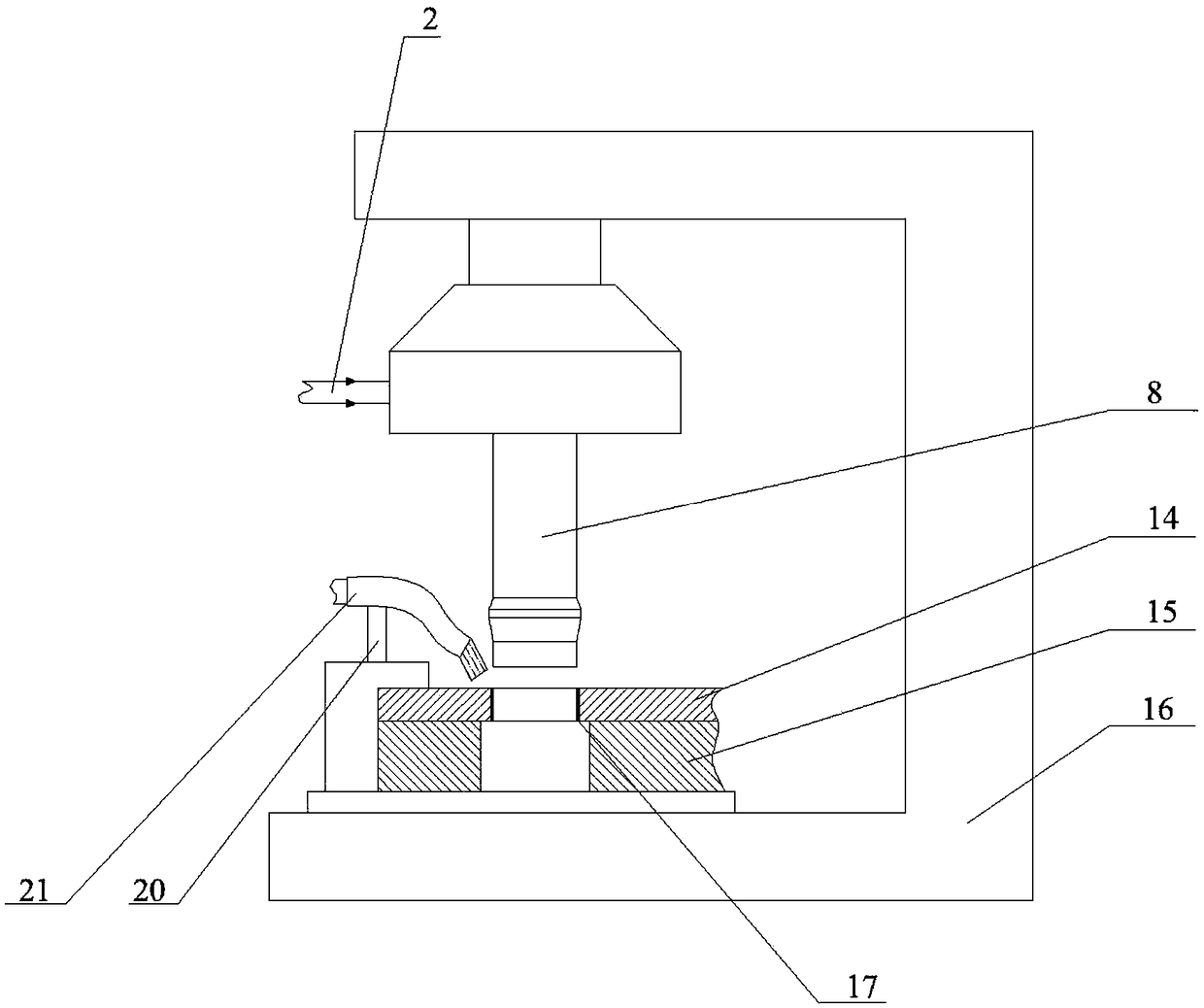

[0039] Both the hole wall laser peening composite extrusion strengthening device described in embodiment 1 and embodiment 2 may include a spray system 21, and the spray system 21 is installed on the fixture 18 for spraying the lubricating liquid 13 on the surface of the workpiece 14 , used for cooling during extrusion strengthening.

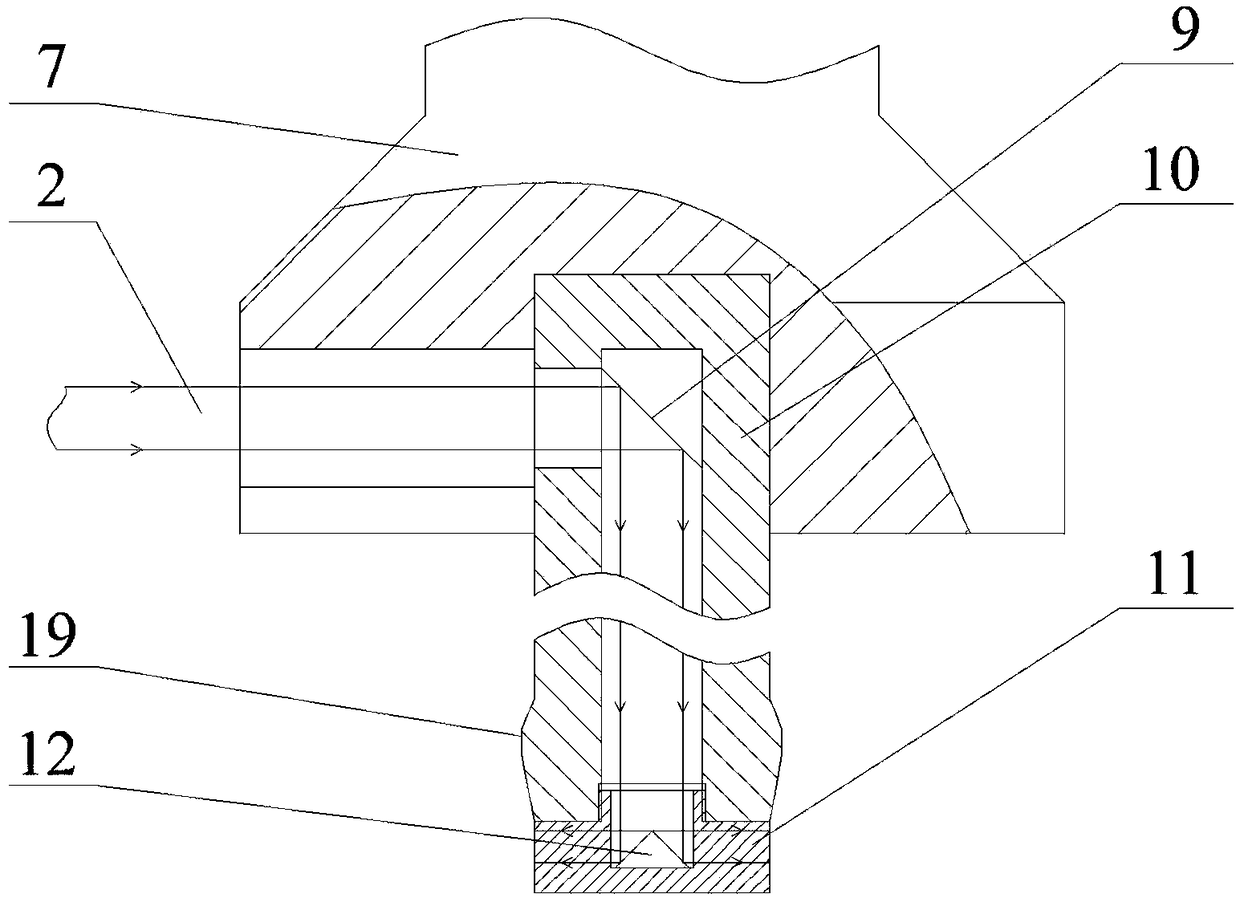

[0040] The mandrel front cone 11 is made of transparent and light-transmitting material; the hardness of the material of the mandrel front cone 11 is 350-500HV; the material of the back cone 10 is high-speed steel. The material of the mandrel front cone 11 is transparent sapphire glass; the material of the rear cone 10 is W6Mo5Cr4V2.

[0041] image 3 As shown, the front cone 11 of the mandrel is in transition fit with the inner hole of the workpiece 14 ; the working section 19 of the mandrel is in interference fit with the inner hole of the workpiece 14 . The diameter of the inner hole of the workpiece 14 is D 2 , the diameter of the mandrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com