Multipurpose inductor-capacitor integrated structure

A multi-purpose, inductive technology, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problem of occupying a large space, achieve the effect of reducing area and space, saving area and space, and remarkable functional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

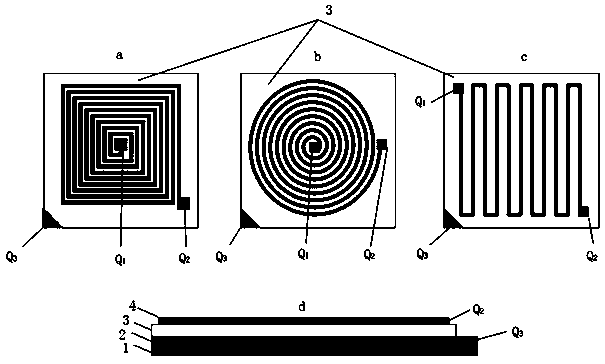

[0030] Specific implementation mode one: as figure 1 As shown, the multipurpose inductance-capacitance integrated structure provided by this embodiment is composed of a substrate 1, a conductive layer 2, a functional material film layer 3 and a conductive coil layer 4, wherein:

[0031] The substrate 1 is provided with a conductive layer 2;

[0032] The conductive layer 2 is used as the electrode Q of the lower layer of the capacitor 3 , which is provided with a functional material film layer 3;

[0033] The functional material thin film layer 3 is used as a capacitor dielectric layer and an inductive magnetic core, on which a conductive coil layer 4 is arranged;

[0034] The conductive coil layer 4 is used as an electrode on the upper layer of the capacitor, and the outer ring end of the conductive coil is used as the output signal terminal Q of the capacitor 2 , the inner end of the coil is used as the capacitor input signal end Q 1 .

[0035] Concrete preparation steps...

specific Embodiment approach 2

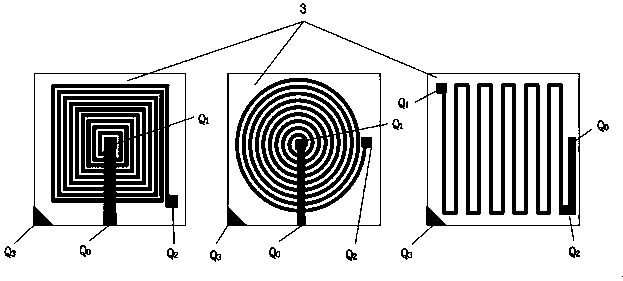

[0042] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the functional material film layer 3 is composed of a dielectric material layer / magnetic material layer, and the dielectric material layer is arranged on the conductive layer 2. The conductive coil layer 4 is disposed on the dielectric material layer, and the magnetic material layer is disposed on the conductive coil layer 4 .

[0043] In this embodiment, the number of layers of the functional material thin film layer and the conductive coil layer is N layers (N is an integer greater than 1), and each layer of functional material thin film layer is provided between the dielectric material layer and the magnetic material layer. layer conductive coil layer. Concrete preparation steps are as follows:

[0044] 1. Prepare a conductive layer on the substrate;

[0045] 2. Prepare a dielectric material layer on the conductive layer;

[0046] 3. Prepare a conductive coil layer on the dielectric mate...

specific Embodiment approach 3

[0055] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the dielectric material layer is disposed on the conductive layer 2, the magnetic material layer is disposed on the dielectric material layer, and the conductive coil layer 4 is disposed on the magnetic material layer superior.

[0056] In this embodiment, the number of layers of the functional material thin film layer and the conductive coil layer is N layers (N is an integer greater than 1), and each magnetic material layer is provided with a layer of conductive coil layer 4 . Concrete preparation steps are as follows:

[0057] 1. Prepare a conductive layer on the substrate;

[0058] 2. Prepare a dielectric material layer on the conductive layer;

[0059] 3. Preparing a magnetic material layer on the dielectric material layer;

[0060] 4. Prepare a conductive coil layer on the magnetic material layer;

[0061] 5. Prepare a dielectric material layer on the conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com