Texturing technology of diamond wire solar battery piece

A technology for solar cells and diamond wire, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of incompatibility of polycrystalline diamond wire texturing process, increased cost, and insignificant anti-reflection effect, etc. Good light trapping effect, improve finished product, improve fill factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

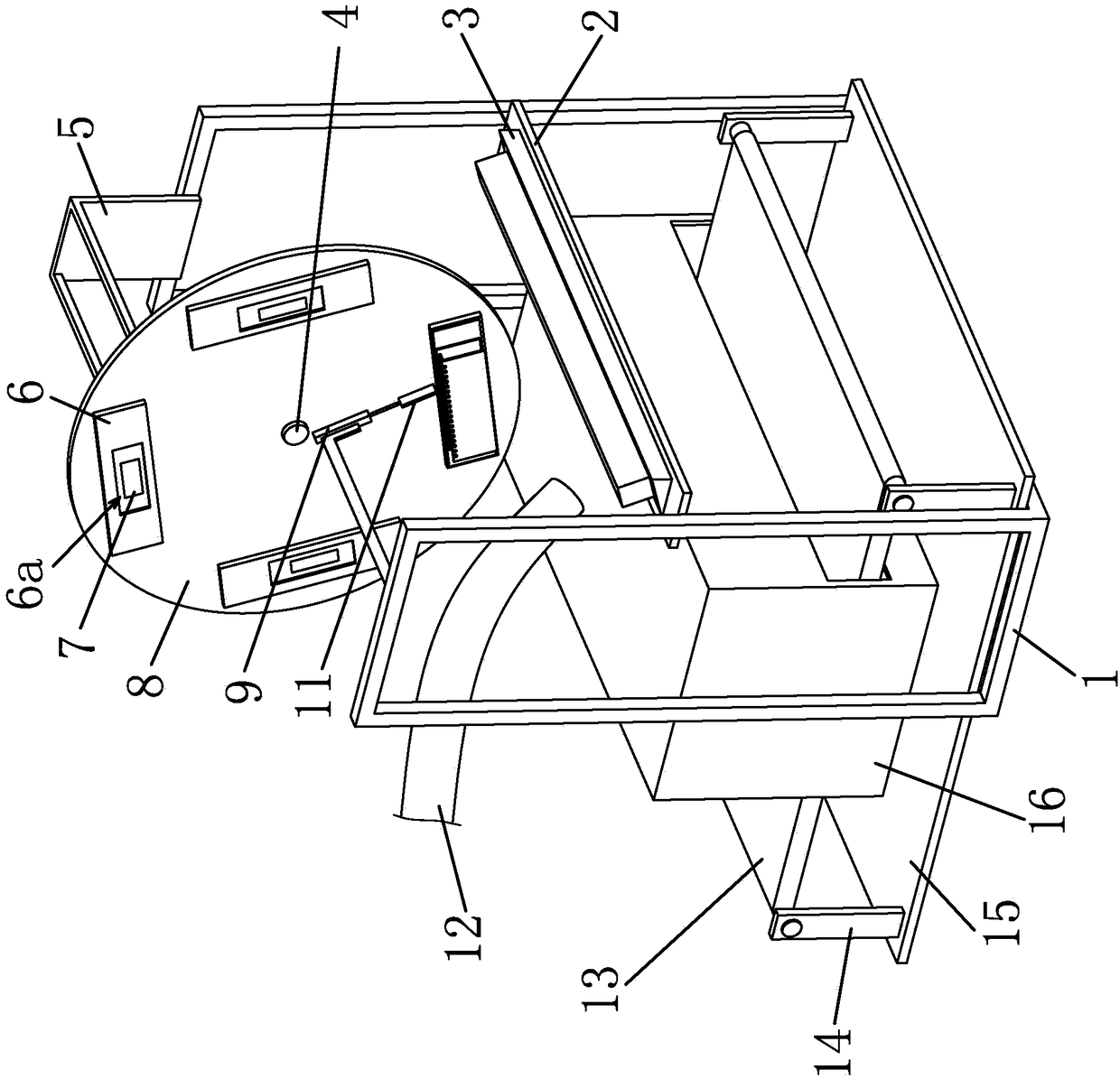

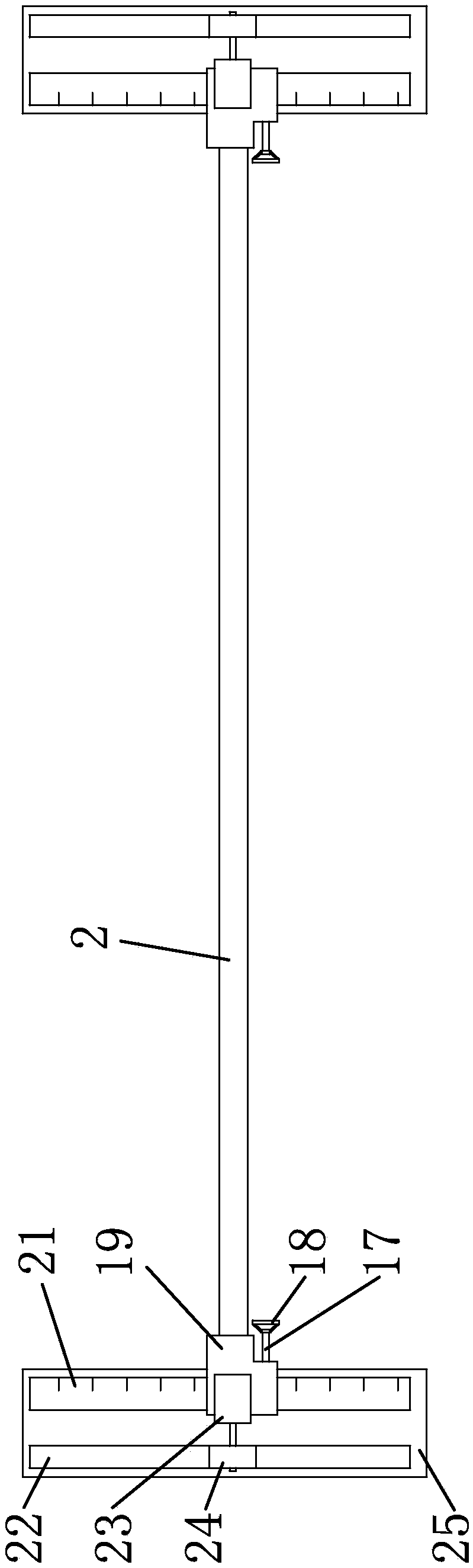

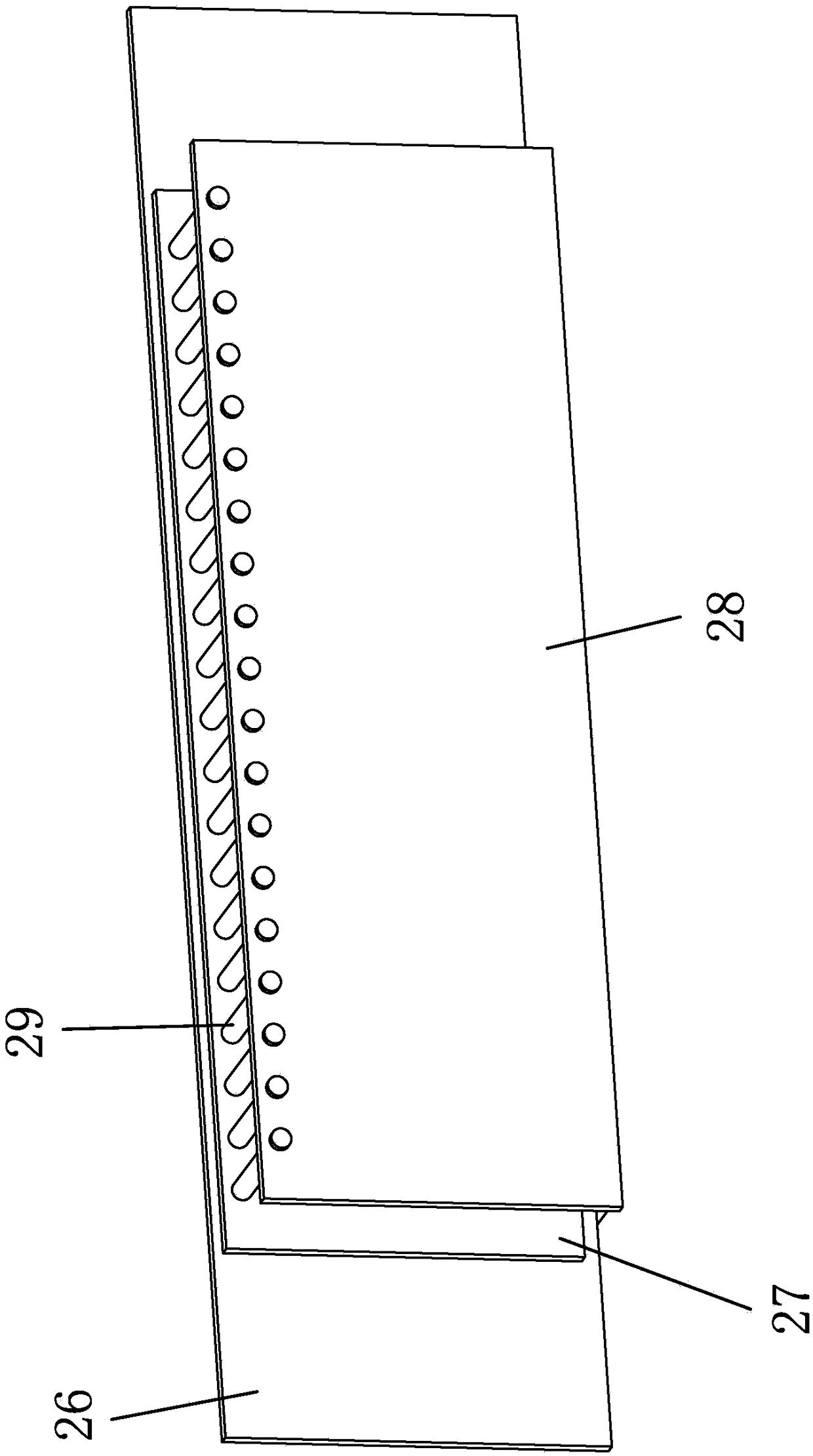

[0081] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0082] The texturing process of the diamond wire solar cells comprises the following steps:

[0083] a. Texturing: immerse silicon wafers in a mixed solution of nitric acid, hydrofluoric acid and water, add polycrystalline additives, and perform acid texturing on silicon wafers;

[0084] b. Clean the surface of the silicon wafer with ultrapure water: use ultrapure water to clean the surface of the silicon wafer to remove the acid on the surface of the silicon wafer;

[0085] c. Alkali cleaning: immerse the silicon wafer in alkaline solution for cleaning to remove the porous silicon on the surface of the silicon wafer and neutralize the residual acid on the surface of the silicon wafer;

[0086] d. Clean the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com