Method and system for low residual multi-stage stripping of vitamin E by-product fatty acid solvent

A technology for vitamins and by-products, applied in the field of vitamin E preparation, can solve the problems of low recovery rate of vitamin E, serious environmental pollution, difficult reaction control, etc., and achieves high purity and recovery rate, low environmental pollution, and easy reaction control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

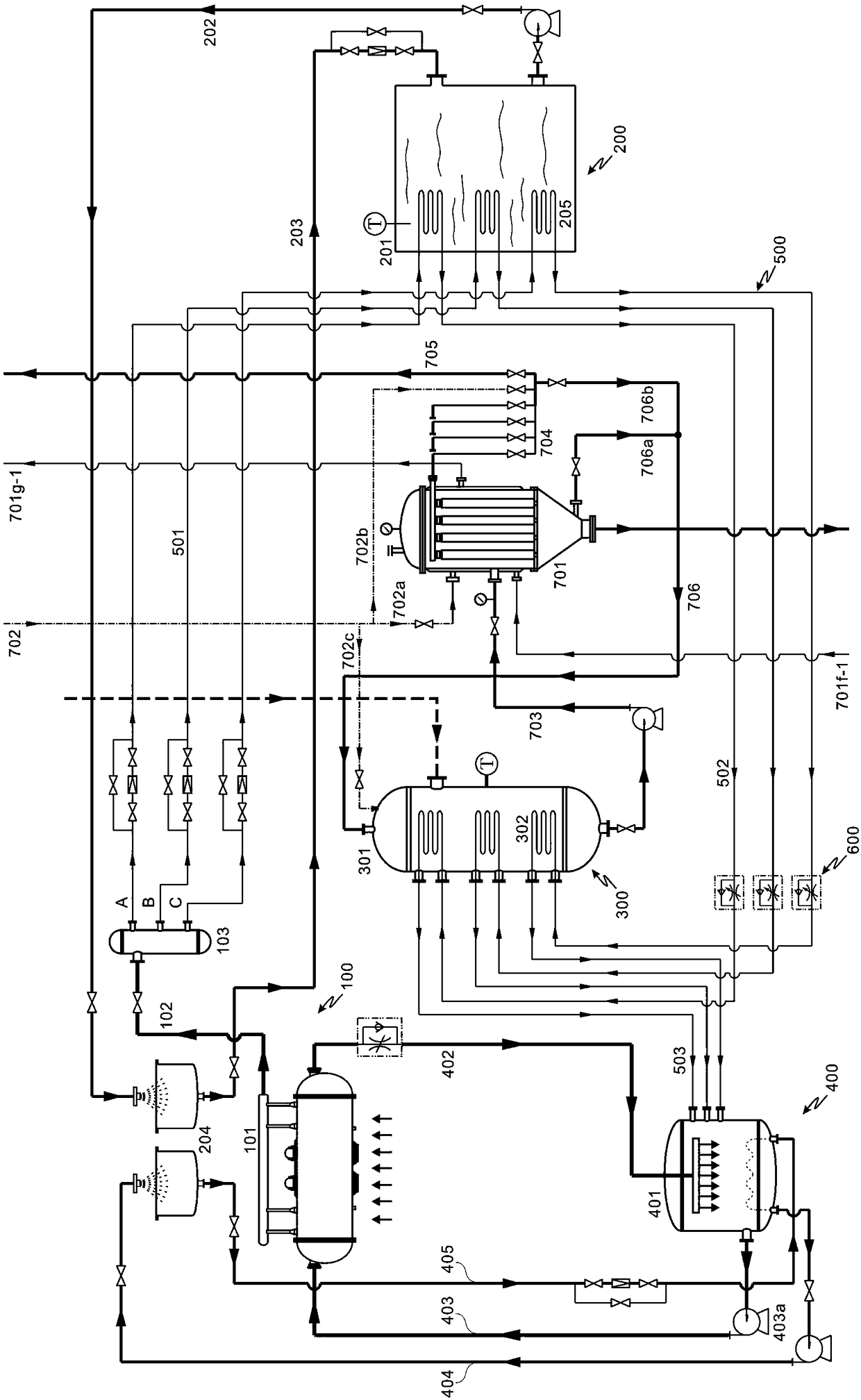

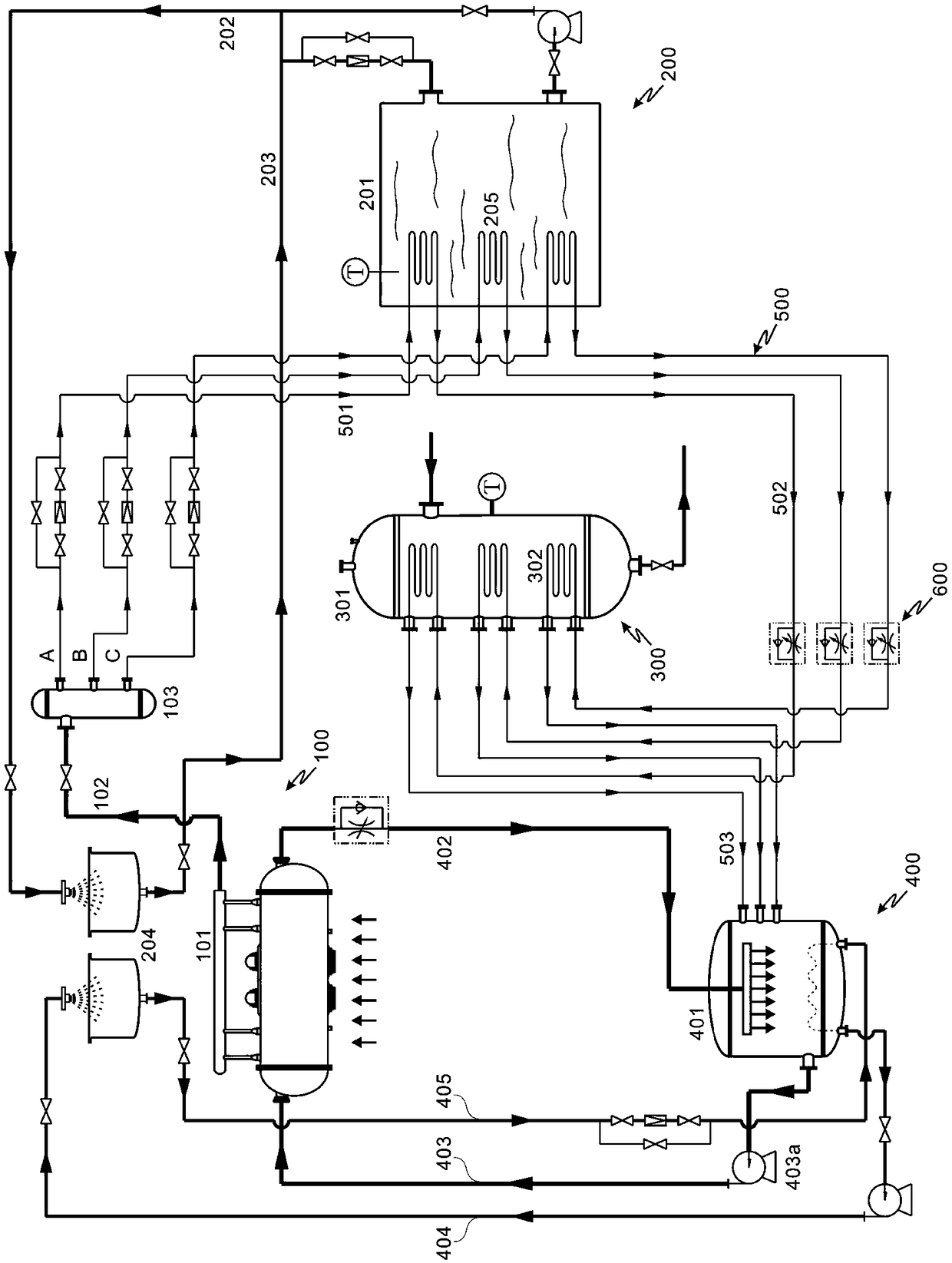

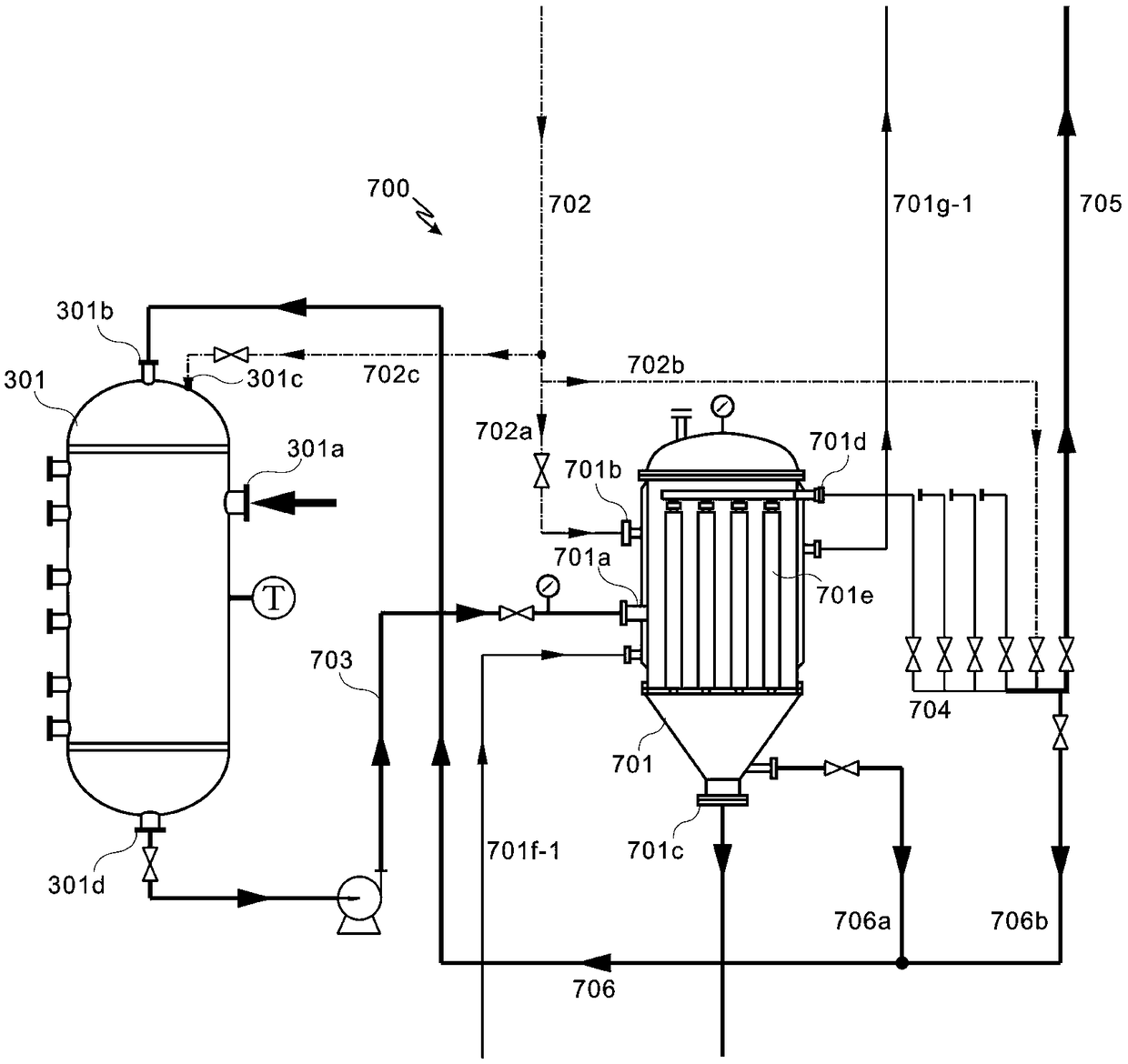

[0029] The present embodiment provides one embodiment of a method for centrifugal separation of 50VE and sterol, comprising:

[0030] Dissolve 1t of soybean oil deodorized distillate in 5000L acetone-methanol mixed solvent (the volume ratio of acetone to methanol is 1.5:1), and inject this mixed solution into the heat dissipation device 301 of the second heat exchange unit 300 for low-temperature crystallization deal with. During this low-temperature crystallization process, the present invention needs to control the initial temperature in the heat dissipation device 301 to be 40°C, and then slowly cool down to -5°C within 4 hours, and keep it for 24 hours to obtain a crystallization mixed solution. Then, the crystallization mixed solution in the cooling device 301 is transferred to the filtration unit 700 for filtration, and the filtrate is centrifuged, washed and dried to obtain a deodorized distillate from which the sterols are removed. The centrifugation is at 6000 rpm for...

Embodiment 2

[0066] Dissolve 1t soybean oil deodorized distillate in 6000L acetone-methanol mixed solvent (the volume ratio of acetone to methanol is 2:1), control the temperature to 35°C, then slowly cool down to -5°C within 5h, and keep 24h, then filtered, the filtrate was centrifuged, washed and dried to obtain the deodorized distillate from which the sterol was removed, and the centrifugation was at 7000rpm for 35min;

[0067] Distill the deodorized distillate from the sterols at a distillation temperature of 230 °C, a feed temperature of 80 °C, and a rotational speed of 120 r / min to obtain distillate and residual liquid respectively; extract, and then evaporate the solvent to obtain a vitamin E product.

[0068] The content of the vitamin E product in Example 2 was measured to be 51.4%, the recovery rate was 82.3%, and the residual volume was 82 ppm.

[0069] The "low-temperature crystallization" and "filtration" in the above-mentioned process of this example are realized by the comb...

Embodiment 3

[0071] Dissolve 1t of corn oil deodorized distillate in 5500L acetone-methanol mixed solvent (the volume ratio of acetone to methanol is 2:1), control the temperature to 40°C, then slowly cool down to -5°C within 6h, and keep 20h, then filtered, the filtrate was centrifuged, washed and dried to obtain the deodorized distillate from which the sterol was removed, and the centrifugation was at 6000rpm for 35min;

[0072] Distilling the deodorized distillate from the sterols at a distillation temperature of 230 °C, a feed temperature of 90 °C, and a rotational speed of 160 r / min to obtain distillate and residual liquid respectively; extract, and then evaporate the solvent to obtain a vitamin E product.

[0073] The content of the vitamin E product in Example 3 was measured to be 50.3%, the recovery rate was 84.1%, and the residual volume was 83 ppm.

[0074] The "low-temperature crystallization" and "filtration" in the above-mentioned process of this example are realized by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com