Forming device for preparing continuous fiber reinforced thermoplasticity prepreg through ultrasonic suspension liquid method

A technology of enhancing thermoplasticity and suspension method, applied in the direction of coating, etc., can solve the problems of rigidity of prepreg, uneven glue content of prepreg, local aggregation of powder, etc., so as to reduce powder agglomeration and improve the formation of transverse crystals. rate, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

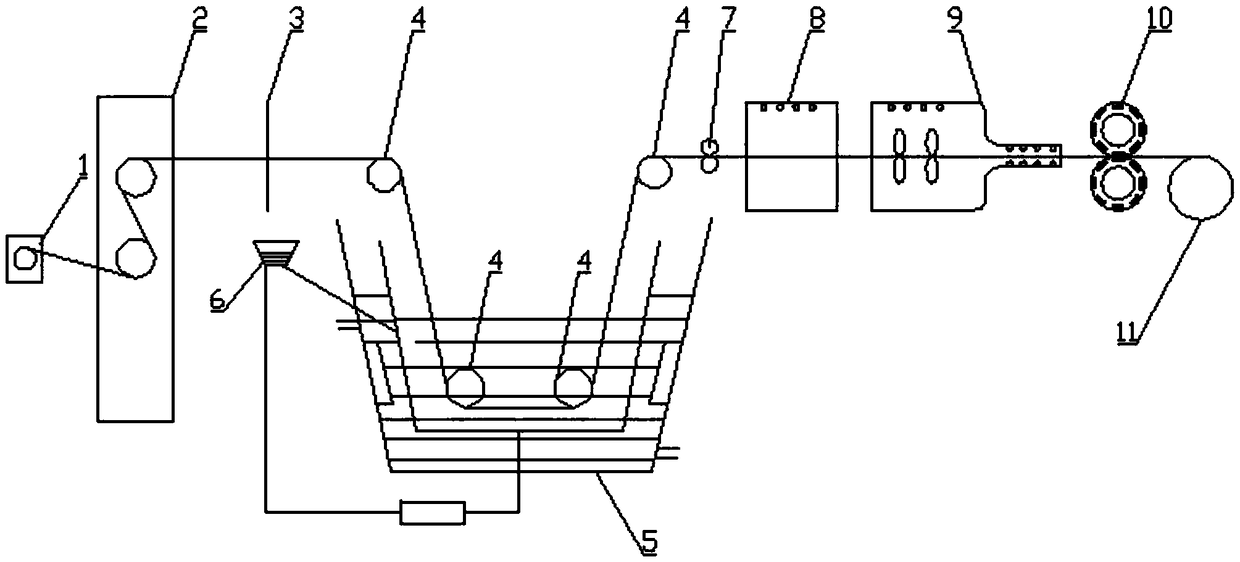

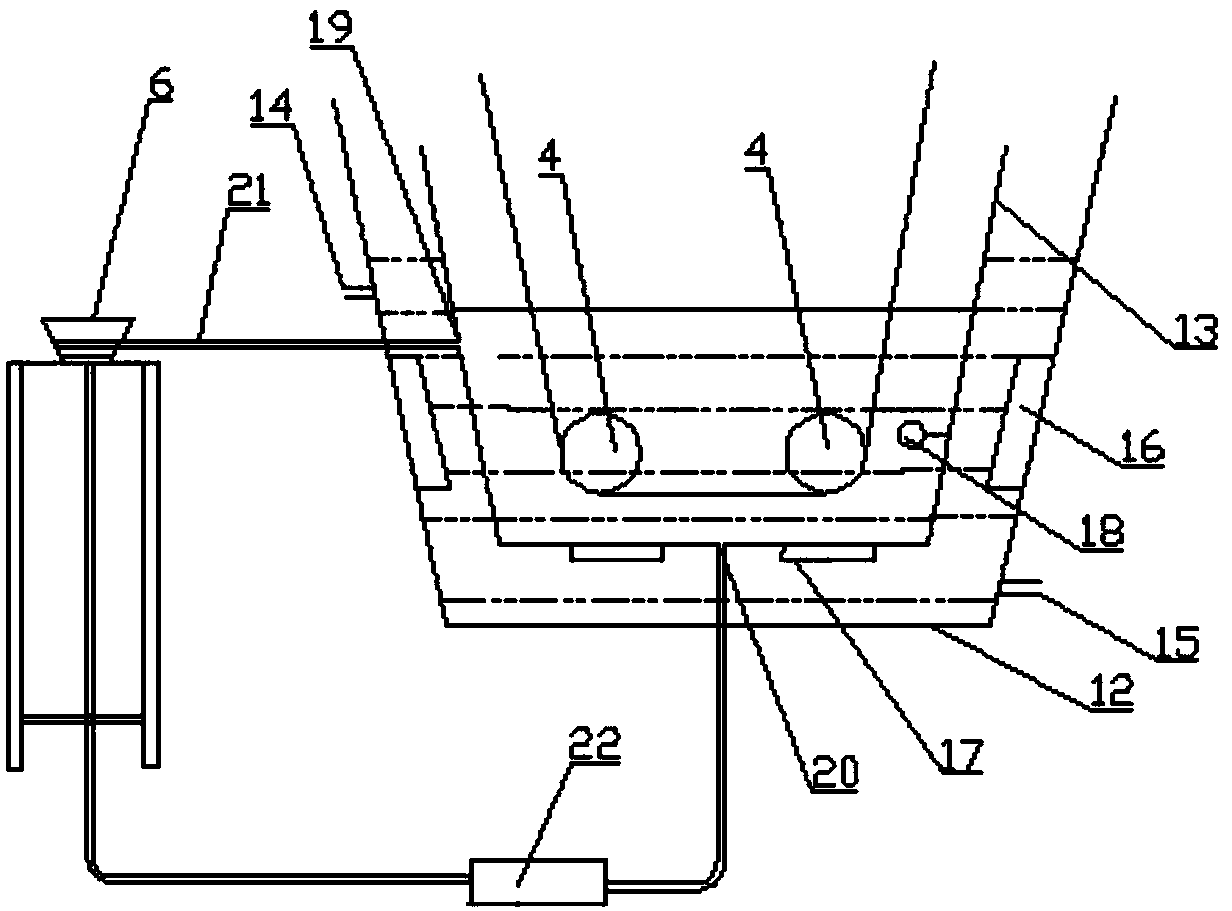

[0034] A molding device for preparing continuous fiber-reinforced thermoplastic prepregs using the ultrasonic suspension method of the present invention is used to prepare continuous carbon fiber-reinforced thermoplastic prepregs. Process flow:

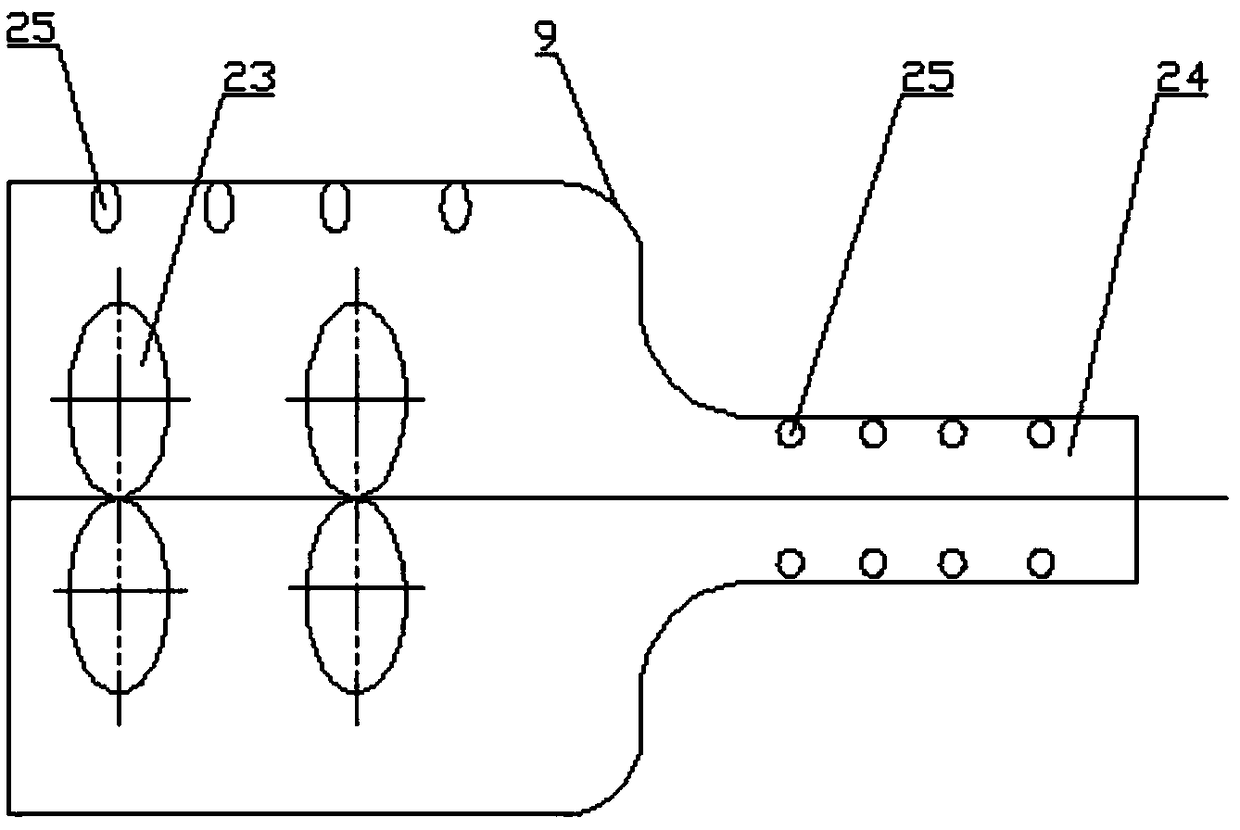

[0035] This technological process comprises two stages, and the first stage is the production preparation stage: at first, open the tap water on the cooling plate 17 on the bottom of the suspension tank 13 and the ultrasonic dispersion tank 12, tap water enters from the water inlet 14 of the ultrasonic dispersion tank 12, The water flows out from the water outlet 15, taking away the heat on the cooling fin 17, and keeping the temperature in the ultrasonic dispersion tank 12 constant at (20°C±3°C). After the temperature is constant for 10 minutes, the airflow powder feeding system 6 is started, and the suspension mixed with polyphenylene sulfide resin powder and deionized water with a particle size of 10 μm passes through the delivery p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com