A kind of carbon fiber thermal insulation soft felt and preparation method thereof

A carbon fiber and soft felt technology, applied in the field of carbon fiber thermal insulation soft felt and its preparation, can solve the problems of carbon fiber application, insufficient safety performance of thermal insulation materials, low self-sufficiency rate, etc., and achieve the effect of uniform performance in all directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In one embodiment, the preparation method of the hollow polyethylene terephthalate fiber comprises the following steps:

[0036] Pre-crystallize PET polyester chips with a weight average molecular weight of 22000 at 145°C for 30 minutes, then dry at 135°C for 2.5 hours, then transport them to a twin-screw extruder for melting at 270-285°C, and use a metering pump to obtain the melt Metered and pressed into the spinning assembly, extruded with a "C" type spinneret, the resulting filaments are cooled and formed by a ring blower, the pressure is 480Pa, the air temperature is 35°C, and the air speed is 0.18-0.20m / s, and then relaxed heat setting, drying, and winding to obtain the hollow polyethylene terephthalate fiber.

[0037] The preparation method of described special-shaped polyethylene terephthalate fiber comprises the steps:

[0038] PET polyester chips with a weight-average molecular weight of 22,000 were pre-crystallized by thermal convection at 145°C for 30 minut...

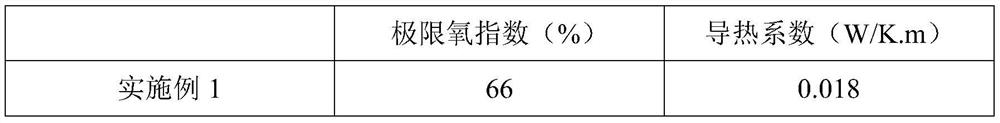

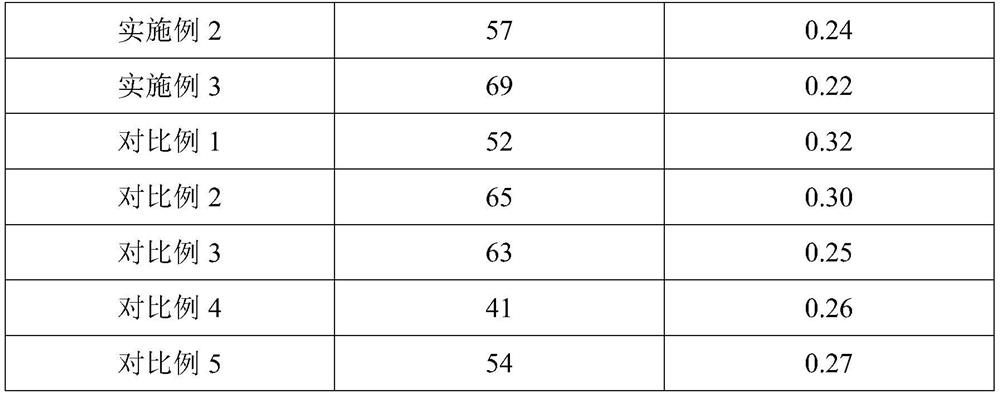

Embodiment 1

[0056] Embodiment 1 provides a carbon fiber thermal insulation soft felt, the carbon fiber thermal insulation soft felt includes a surface layer and a composite cotton mesh layer; the thickness of the surface layer and the thickness ratio of the composite cotton mesh layer are 1:2.2; the composite cotton mesh layer The raw materials for the preparation of the layer consisted of 20 parts by weight of polyester fiber and 38 parts by weight of carbon fiber.

[0057] The surface layer is prepared from a zigzag folded fiber web; the folding angle of the zigzag folded fiber web is 45 degrees; the polyester fiber is polyethylene terephthalate fiber; the polyethylene terephthalate fiber The ethylene formate fiber is composed of hollow polyethylene terephthalate fiber and special-shaped polyethylene terephthalate fiber, and its weight ratio is 1:3.2; the carbon fiber is pitch-based carbon fiber; the pitch-based carbon fiber The degree of crimp is 6%; The preparation method of described...

Embodiment 2

[0067] Embodiment 2 provides a carbon fiber thermal insulation soft felt, the carbon fiber thermal insulation soft felt includes a surface layer and a composite cotton mesh layer; the thickness of the surface layer and the thickness ratio of the composite cotton mesh layer are 1:1.8; the composite cotton mesh layer The raw materials for the preparation of the layer consisted of 15 parts by weight of polyester fiber and 30 parts by weight of carbon fiber.

[0068] The surface layer is prepared from a zigzag folded fiber web; the folding angle of the zigzag folded fiber web is 30 degrees; the polyester fiber is polyethylene terephthalate fiber; the polyethylene terephthalate fiber The ethylene formate fiber is composed of hollow polyethylene terephthalate fiber and special-shaped polyethylene terephthalate fiber, and its weight ratio is 1:2.5; the carbon fiber is pitch-based carbon fiber; the pitch-based carbon fiber The degree of crimp is 4%; The preparation method of described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com