A kind of preparation method of azide grafting modified nitrocellulose microspheres

A technology of nitrocellulose and graft modification, which is applied in the field of new energetic materials, can solve the problems of unstable control of formula component content, poor technological performance of medicinal slurry, increased viscosity of medicinal slurry, etc., so as to improve uniform dispersion. and physical compatibility, improve the preparation process, and improve the effect of plasticizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

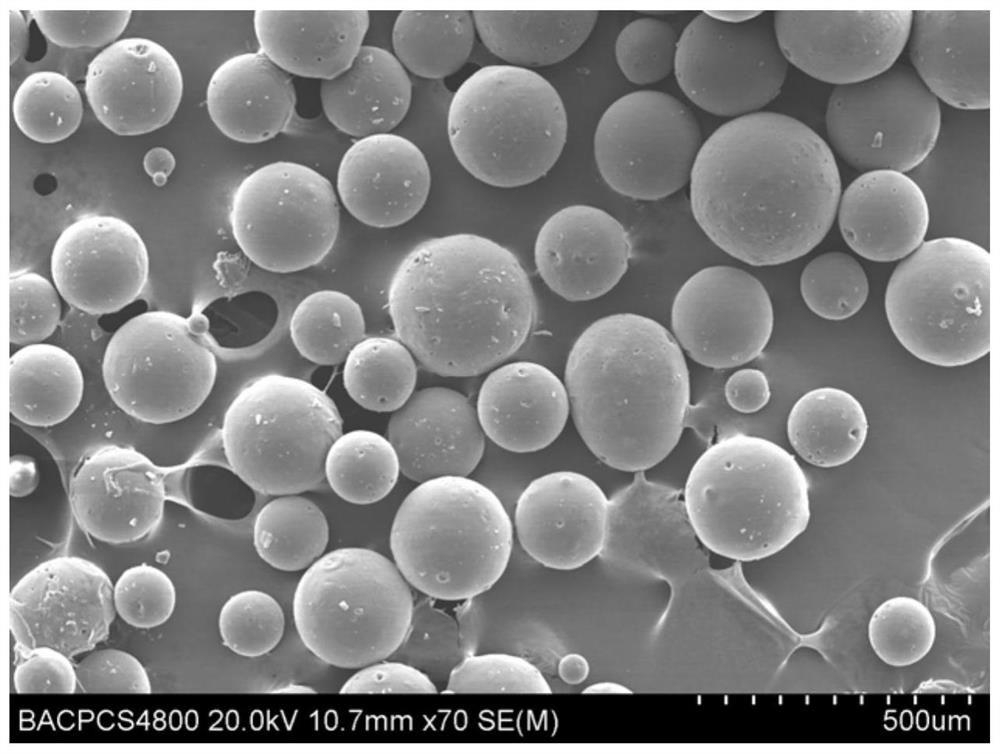

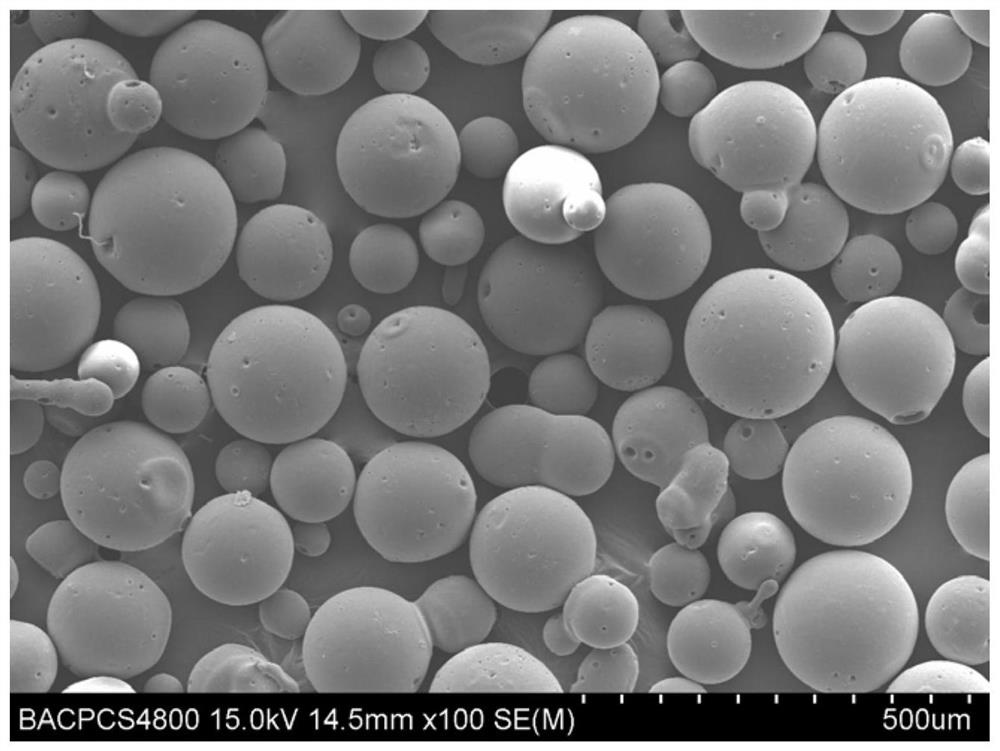

Examples

Embodiment 1

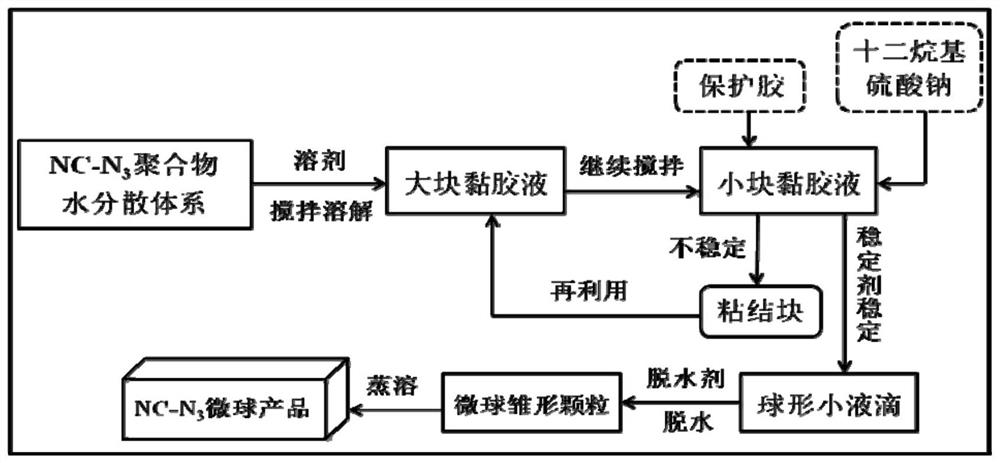

[0038] A kind of NC-N 3 The preparation method of microsphere, its process comprises the steps:

[0039] Step 1: Add 5.0g NC-N to the reactor 3 , then add 65g of dispersant water, start the agitator to stir and heat at a speed of 320 rpm to form a dispersion system;

[0040] Step 2: When the temperature rises to 65°C, slowly add 35.0 g of ethyl acetate solvent dropwise to the dispersion system prepared in the first step, and after the addition of the solvent is completed, adjust the stirring speed to 550 rpm and continue stirring for 60 minutes into small pieces of viscose;

[0041] The third step: take by weighing 1.5g gelatin and be mixed with 10.0% protective glue aqueous solution, join in the small piece viscose liquid that the second step makes, add 0.024g sodium lauryl sulfate after stirring for 60 minutes, Continue to stir for 25 minutes to form an "oil-water" type stable emulsion, in which the cohesive blocks formed without being stabilized by the protective glue ca...

Embodiment 2

[0047] A NC-N 3 The preparation method of microsphere, its process comprises the steps:

[0048] Step 1: Add 5.0g NC-N to the reactor 3 , then add 75g of dispersant water, start the agitator to stir and heat at a speed of 320 rpm to form a dispersion system;

[0049] Step 2: When the temperature rises to 65°C, slowly add 45.0 g of ethyl acetate solvent dropwise to the dispersion system prepared in the first step, and after the addition of the solvent is completed, adjust the stirring speed to 600 rpm and continue stirring for 60 minutes into small pieces of viscose;

[0050] The third step: take by weighing 2.0g white gelatin and be mixed with 10.0% protective glue aqueous solution, join in the small piece viscose liquid that the second step makes, add 0.030g sodium lauryl sulfate after stirring for 60 minutes, Continue to stir for 25 minutes to form an "oil-water" type stable emulsion, in which the cohesive blocks formed without being stabilized by the protective glue can ...

Embodiment 3

[0056] A kind of NC-N 3 The preparation method of microsphere, its process comprises the steps:

[0057] Step 1: Add 5.0g NC-N to the reactor 3 , then add 85g of dispersant water, start the agitator to stir and heat at a speed of 320 rpm to form a dispersion system;

[0058] Step 2: When the temperature rises to 65°C, slowly add 55.0 g of ethyl acetate solvent dropwise to the dispersion system prepared in the first step, and after the addition of the solvent is completed, adjust the stirring speed to 650 rpm and continue stirring for 60 minutes into small pieces of viscose;

[0059] The 3rd step: take by weighing 2.5g white gelatin and be mixed with 10.0% protective glue aqueous solution, join in the small piece viscose liquid that the second step makes, add 0.034g sodium lauryl sulfate after stirring for 60 minutes, Continue to stir for 25 minutes to form an "oil-water" type stable emulsion, in which the cohesive blocks formed without being stabilized by the protective glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com