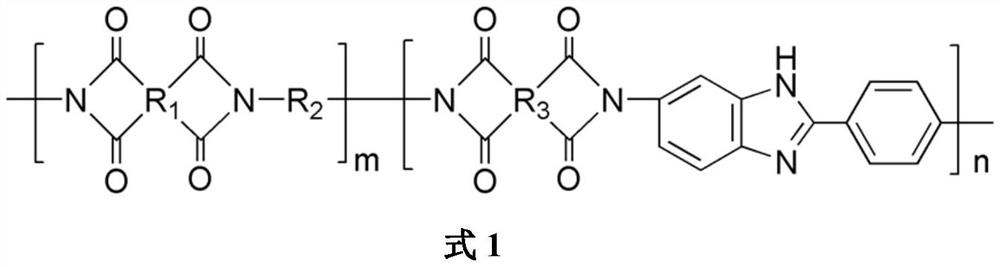

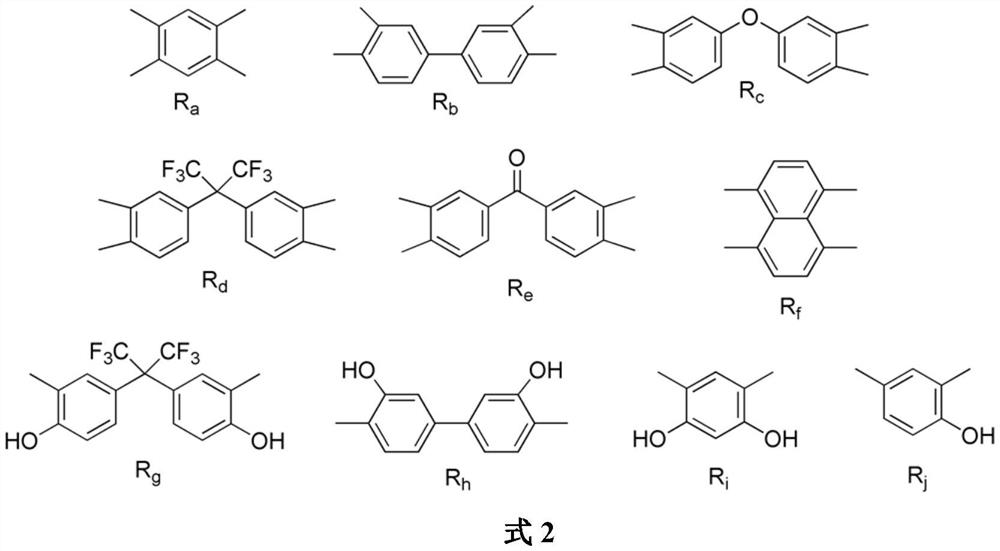

Structure, preparation method and application of anti-plasticizing effect polyimide copolymer gas separation membrane

A technology of gas separation membrane and polyimide, applied in separation methods, chemical instruments and methods, gas fuels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Under nitrogen protection, in a 250mL three-necked flask equipped with a mechanical stirrer, first add 6FAP (1.0000g, 6.6mmol) and imidazole diamine (1.5080g, 6.6mmol), then add anhydrous NMP (100mL), wait for After the diamine was completely dissolved, PMDA (2.9038 g, 13.2 mmol) was added, and the solution was reacted at 20° C. for 5 h to obtain the corresponding polyamic acid solution.

[0019] 2. Add 0.1 g of isoquinoline and 50 mL of 1,2-dichlorobenzene to the polyamic acid solution obtained in step 1, and continue to react at a temperature of 175-200 ° C for 12-24 h to obtain a polyimide solution; after cooling The obtained polyimide solution was slowly poured into stirring anhydrous methanol, and the precipitate was washed with anhydrous methanol for several times, filtered, and continuously dried under vacuum at 120° C. for 12 h to obtain a polyimide solid.

[0020] 3. At room temperature, the polyimide solid obtained in step 2 is dissolved in a mixed solution...

Embodiment 2

[0023] 1. Under nitrogen protection, in a 100mL three-necked flask equipped with a mechanical stirrer, first add BIDA (1.2000g, 5.3mmol) and ODA (1.0697g, 5.3mmol), then add anhydrous NMP (30mL), wait for the diamine After complete dissolution, 6FDA (4.7261 g, 10.6 mmol) was added, and the corresponding polyamic acid solution was obtained after 5 h of reaction at room temperature.

[0024] 2. Add 0.4 g of isoquinoline and 15 mL of xylene to the polyamic acid solution obtained in step 1, and continue the reaction at 175-200 ° C for 12-24 h to obtain a polyimide solution; then the obtained polyamide The imine solution was slowly poured into the stirring anhydrous methanol, and the precipitate was washed with anhydrous methanol for many times, filtered, and continuously dried under vacuum at 150 °C for 12 h to obtain a polyimide solid.

[0025] 3. At room temperature, the polyimide solid obtained in step 2 is dissolved in DMF to prepare a polyimide solution with a concentration o...

Embodiment 3

[0030] 1. Under nitrogen protection, in a 100mL three-necked flask equipped with a mechanical stirrer, first add BIDA (2.0000g, 9.0mmol) and ODA (0.5943g, 3.0mmol), then add anhydrous NMP (30mL), wait for the diamine After complete dissolution, 6FDA (5.2513 g, 12.0 mmol) was added, and the corresponding polyamic acid solution was obtained after 5 h of reaction at room temperature.

[0031] 2. Add 0.5 g of isoquinoline and 15 mL of xylene to the polyamic acid solution obtained in step 1, and continue to react at 175-200 ° C for 12-24 h to obtain a polyimide solution; then the obtained polyamide The imine solution was slowly poured into the stirring anhydrous methanol, and the precipitate was washed with anhydrous methanol for many times, filtered, and continuously dried under vacuum at 150 °C for 12 h to obtain a polyimide solid.

[0032]3. At room temperature, the polyimide solid obtained in step 2 is dissolved in DMF to prepare a polyimide solution with a concentration of 2%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com