Barrel-mixed pesticide synergistic auxiliary and method for preparing same

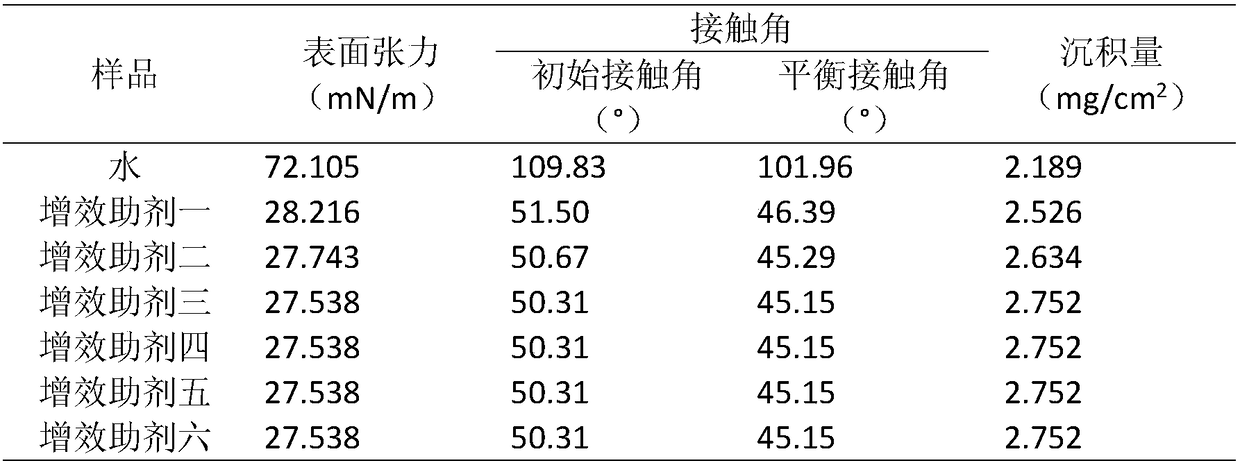

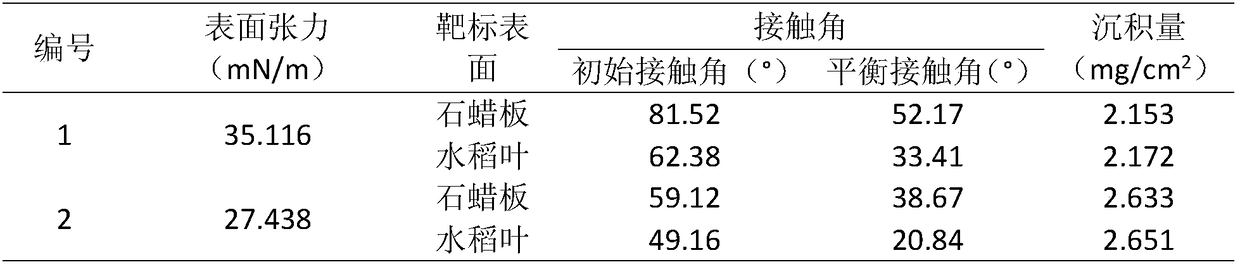

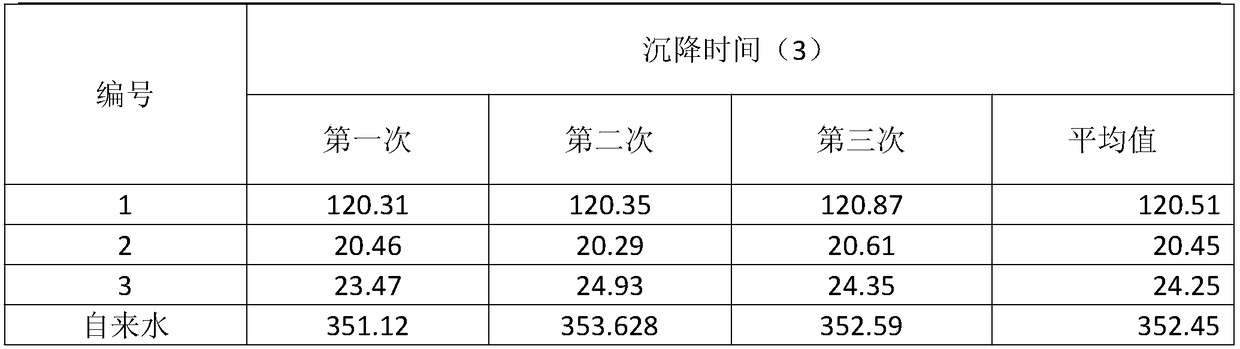

A technology of synergistic adjuvants and pesticides, applied in botany equipment and methods, insecticides, biocides, etc., can solve the problems of low effective utilization of pesticides, difficult penetration of pesticide liquid, easy bouncing and rolling, etc., to achieve Effects of prolonged drying time, improved solubility, and reduced surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of the oil-based pesticide synergist of the present invention one

[0022] Ratio of various raw materials: Thione: 5%, lecithin 20%, vitamin E 10%, emulsifier 10% (Nongru 500#5%, Nongru 600#3%, cashew oil polyoxyethylene ether 2%), Spreading agent Silwet 4085%, 150# solvent naphtha 30%, methylated soybean oil 20%.

[0023] Preparation method: Weigh 5kg of thioketone, 20kg of lecithin, 10kg of vitamin E, 5kg of agricultural milk 500#, 3kg of agricultural milk 600#, 2kg of cashew nut oil polyoxyethylene ether, 5kg of spreading agent, 30kg of 150# solvent oil, methyl ester 20kg of soybean oil, a total of 100 kilograms. At a constant temperature of 40°C, under magnetic stirring, add lecithin to the solvent in sequence, after fully dissolving, then add vitamin E, then sequentially add thione, emulsifier, and finally add spreading agent, fully stir until the solution is uniform, that is Get synergist one.

Embodiment 2

[0024] Embodiment 2: Preparation of oil-based pesticide synergist II according to the present invention

[0025] Proportion of various raw materials: Thione: 10%, lecithin 10%, vitamin E 5%, emulsifier 10% (Nongru 500#5%, Ningru 33#3%, castor oil polyoxyethylene ether 2%) , Spreading agent Silwet 4085%, 150# solvent naphtha 30%, methylated soybean oil 30%.

[0026] Preparation method: Weigh 10kg of thilone, 10kg of lecithin, 5kg of vitamin E, 5kg of agricultural milk 500#, 3kg of 33#, 2kg of castor oil polyoxyethylene ether, 4085kg of spreading agent Silwet, 30kg of 150# solvent oil, methylate 30kg of soybean oil, 100kg in total. At a constant temperature of 40°C, under magnetic stirring, add lecithin to the solvent in sequence, after fully dissolving, then add vitamins, then sequentially add thioketone, emulsifier, and finally add spreading agent, stir well until the solution is uniform, that is, Synergist II.

Embodiment 3

[0027] Example 3: Preparation of the oil-based pesticide synergist of the present invention III

[0028] Various raw material ratios: Azone: 20%, lecithin 5%, vitamin E 5%, emulsifier 10% (Nongru 500#4%, Nongru 600#3%, fatty alcohol polyoxyethylene ether 3%), Spreading agent Silwet 4085%, 150# solvent naphtha 35%, methylated soybean oil 15%.

[0029] Preparation method: Weigh 10kg of azone, 5kg of lecithin, 5kg of vitamin E, 4kg of agricultural milk 500#, 3kg of agricultural milk 602#, 3kg of fatty alcohol polyoxyethylene ether, 5kg of spreading agent, 35kg of 150# solvent oil, methyl ester 30kg of soybean oil, a total of 100 kilograms. At a constant temperature of 40°C, under magnetic stirring, add lecithin in sequence in the solvent, after fully dissolving, then add vitamins, followed by azone, emulsifier, and finally add spreading agent, fully stir until the solution is uniform, that is, Synergist three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com